Hello all, I have made more progress on the model.

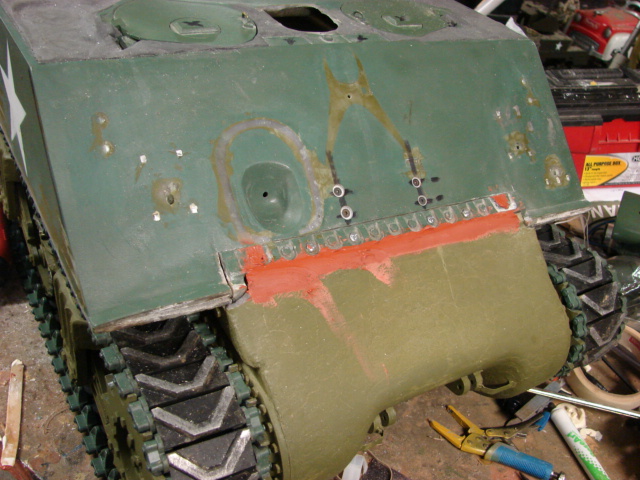

After completing most of the lower hull details I gave the lower hull a shot of primer and I applied it's preliminary base coat of OD. The rubber tires have been masked to protect them from any over spray.

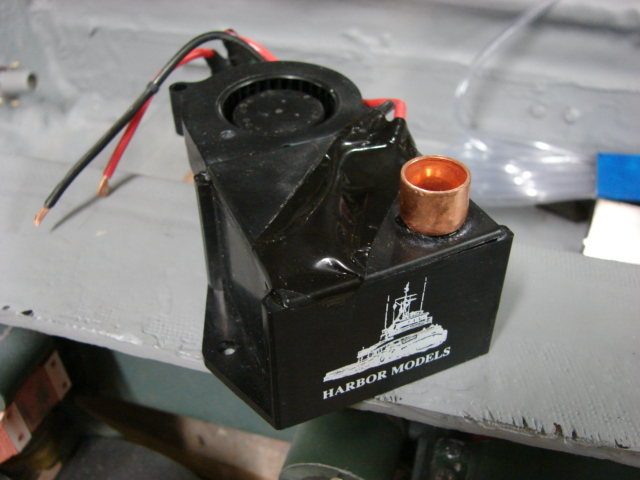

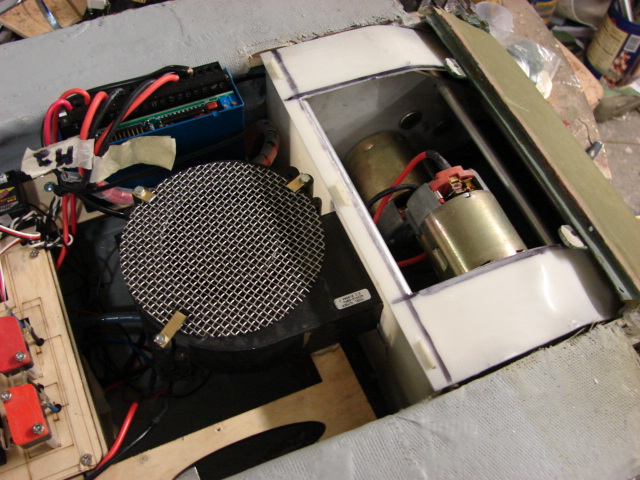

After the model was painted it was time to add the machinery. First I added the tank's smoke generators. For the main engine exhaust I used this smoke generator from harbormodels.com. I have used this system before in the King tiger and jagdpanther and I have no complaints on the system.

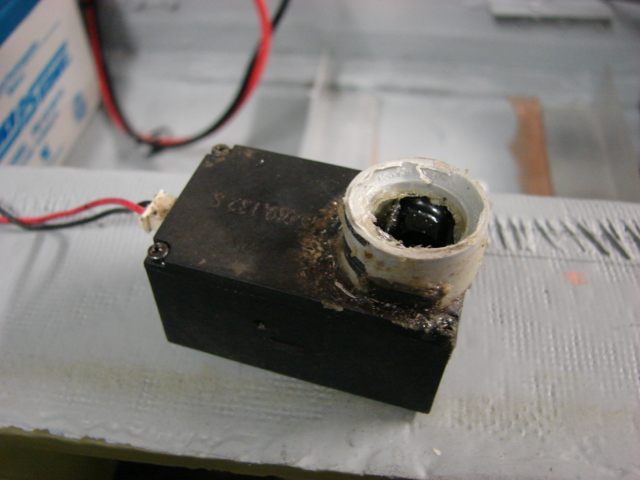

For the little Joe generator smoke I used this smaller smoke generator that I had on hand. This smaller generator emits less smoke, which is why I’m using it for this application.

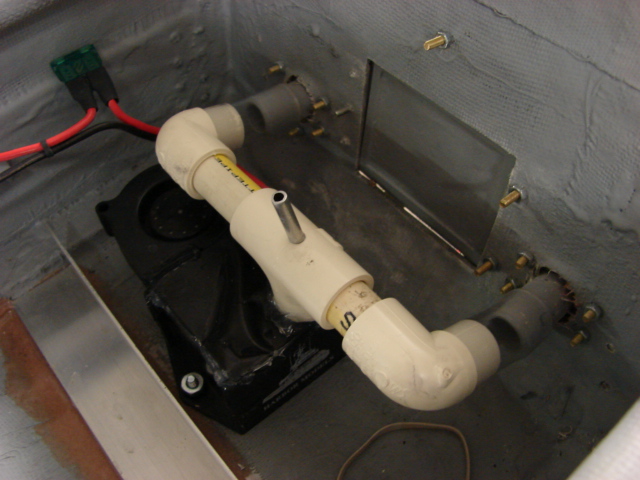

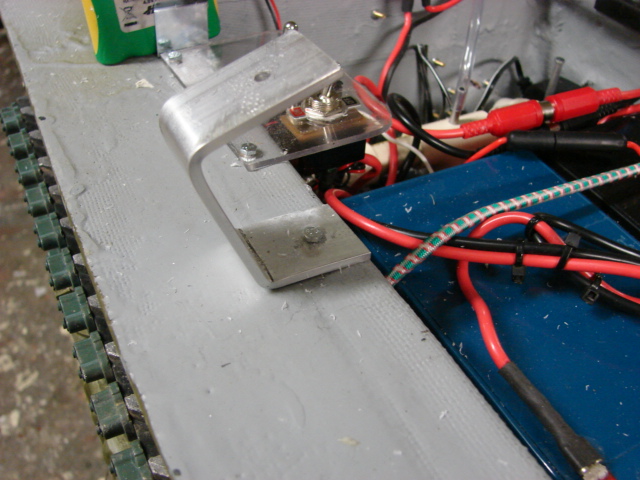

As in my other RC tanks with smoke I build into the model it's own on board smoke fluid refilling pump system. To do this I use a small RC fuel pump.

The pump refills the smoke fluid reservoir when they run low. To make the power switch more reachable I fabricated this handle out of an aluminum tube and a long bolt.

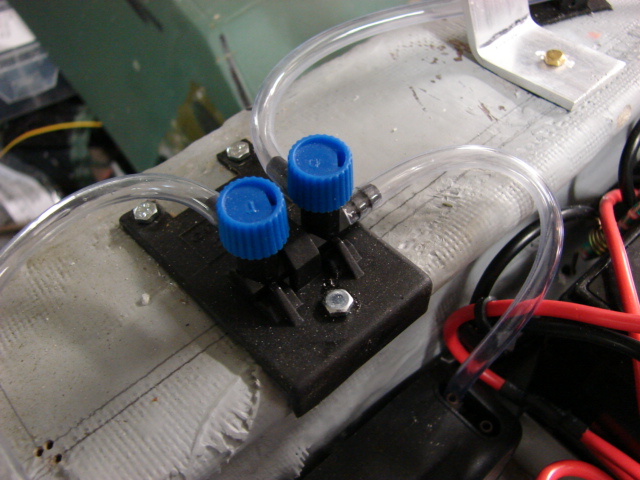

Since this model is equipped with two generators I needed to mount a valve system so I can control which generator gets refilled. To do this I mounted an aquarium gang valve to the model. With this I can refill both at one time or each of them individually.

All the refueling system needs to complete it is the refill hose. This is the hose that will extend out of the vehicle so I can refill the generators from a distance. This is done to minimize any chance of spilling the smoke fluid onto the model which can ruin the finish.

As for the smoke system I'm currently waiting for an electronic speed controller to arrive. Once it arrives I can complete the system so that it has proportional throttle smoke. The system will also be able to switch from main engine smoke to generator smoke as per the real vehicle.

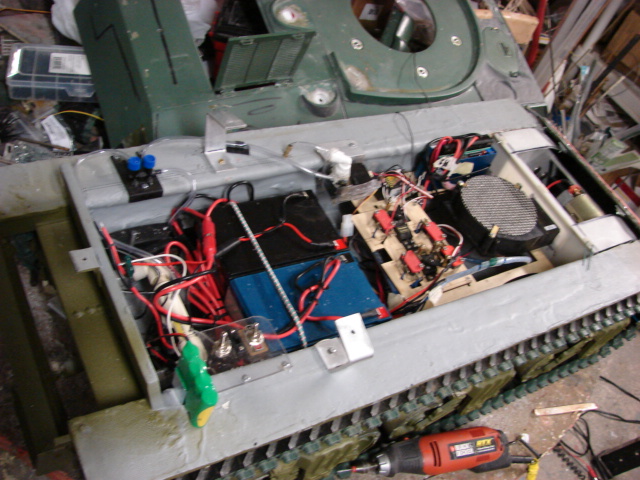

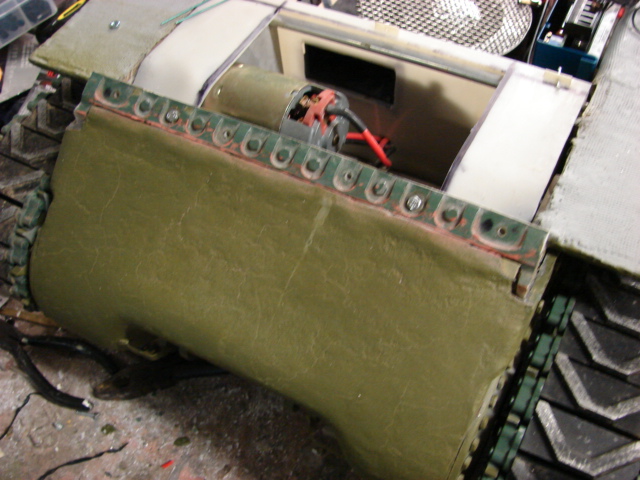

After the smoke system I concentrated on the rest of the tank's electronics. I relocated the tank's kit supplied servo tray to the center of the vehicle. I needed the back end to house the batteries so I can get easy access to them for recharging. The exposed turret rotation and gun elevation control servos will be encased in a plastic box to keep from getting snagged by any umbilical cord wiring that will enter into the turret.

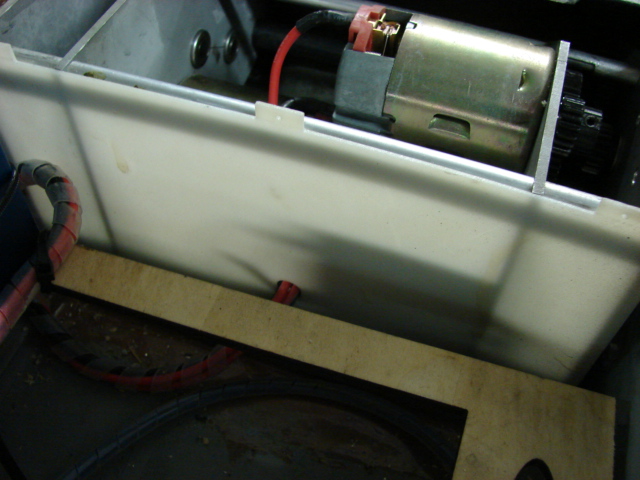

The tank's gear box came with a dust cover. this cover completely covers up both the motors and the gears from the top and back . Before the addition of the sponsons you would need this feature, but with the addition of the sponson sealing up the lower hull the dust cover becomes redundant.

After driving the tank out doors I noticed that the motors get very hot. If you have them encased with the cover while driving the tank even without the sponsons I feel that the motors will over heat and possibly burn out.

Even though the dust cover will no longer be needed to keep debris out of the gear box I decied to modify the cover to only cover the gear sections. I did this because when you lubricate the gears oil and grease will be flung all over the tank's interior. I also did this to prevent any wires or other matierals to be caught into the gears causing unwanted damage. To make the mod I simply cut out the center section of the top dust cover leaving the center with the motors exposed.

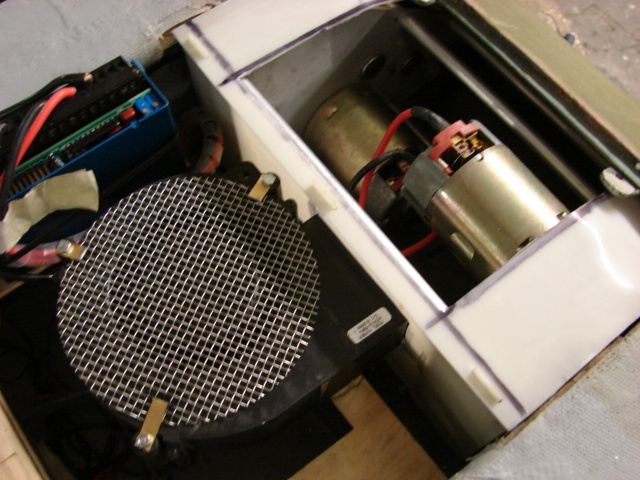

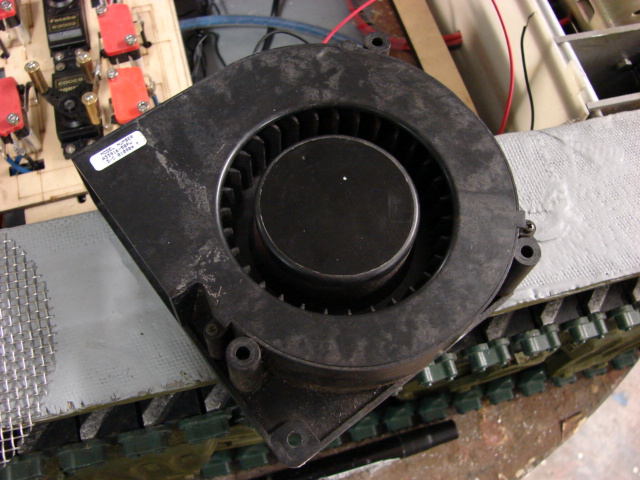

With the center removed the motors now have more air to breathe, and the gears are still protected. To cool the motors off further cut a hole in the rear portion of the dust cover and I mounted a large PC blower cooling fan.

The blower fan I also had lying around the shop

The 12volt fan was another component I had lying around the shop. It is very powerful and does exert alot of air

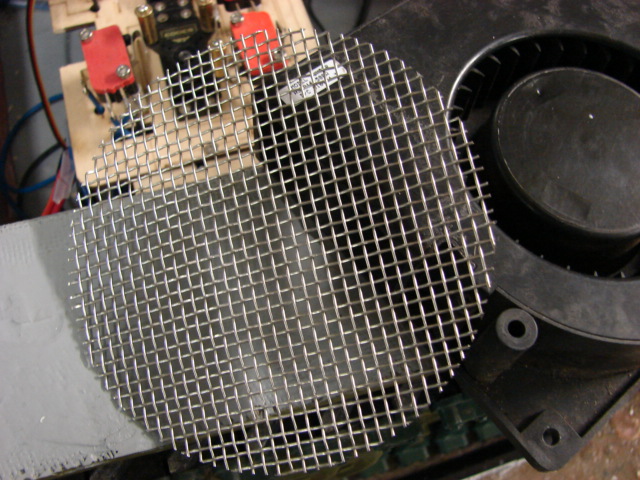

To protect the fan and to prevent any wires or other foreign material to fall inside I fabricated a fan guard out of a spare metal grill. The grill is actually a spare from the Armortek king tiger. Brass strips were soldered to the sides and the component was added.

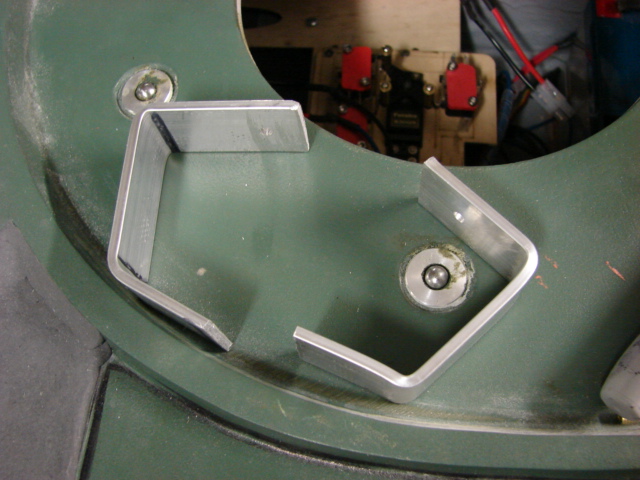

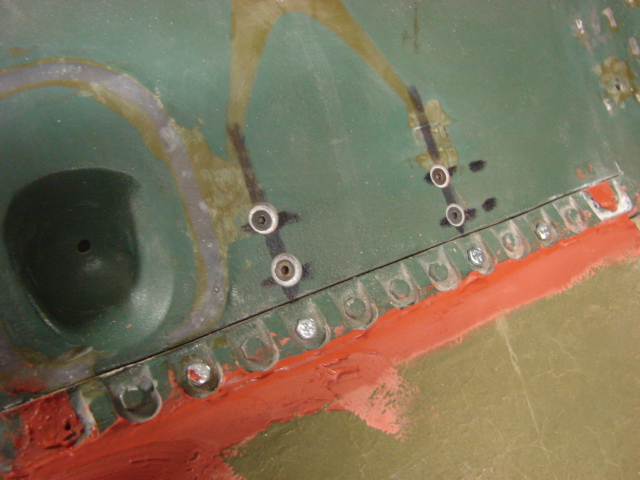

The last revision I was able to make to the model was the upper hull mounts. On the stock model the upper hull and lower hull were secured with three bolts. One in the center rear and two along the transmission cover. This system was simple, but not only hurt the look of the model, the rear portion still had some wobble to it. To correct this I redesigned the kit mounts. To mount the tank in the rear I decided to conceal the new bolts under the fuel caps.

The molded in fuel caps were removed, and the holes were cleaned up.

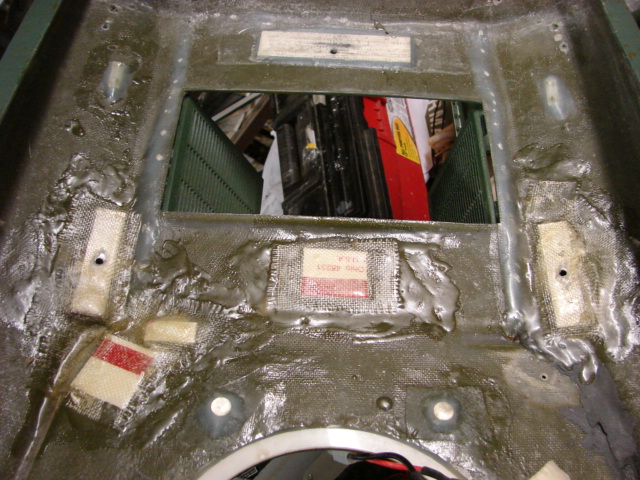

Aluminum strips were mounted to the hull and were fiberglassed into the upper hull shell.

for the lower hull I fabricated the mounts out of two bent strips of Aluminum . These mountes were bolted to the hull.

The new bolts simply bolt into these locations. This new design eliminates the wobble that was present with the kit design. As the build progresses I will be adding the functional fuel cap covers, and I will be reworking the bolt heads to look like the fuel filler caps so I can still display the fuel caps open.

In an earlier post I had written that the transmission rivet strip was molded into the upper hull and that I was going to leave it and tolerate a small seam there the two hulls met. After much decision I decided that the seam was unacceptable and I decided to rework the transmission cover mounting further.

To make the alteration I had to first remove the molded in transmission strip and to permanently bolt and mount the strip to the tank. To remove the strip I used the Dremel multimax to perkily cut out the part.

To mount the hull to the front transmission I mounted two aluminum strips to the front plate. These strips were mounted with counter sunk bolts. These bolts will be coved up with epoxy and body work leaving a smooth surface.

Now the front will mount to the transmission bolt strip using two bolts that are located on the bolt strip. With this design I can still remove the upper hull, but I will have no seam running along the transmission cover which on the real tank is a solid unit, rather I have moved the small seam to a location that is found on the actual vehicle.

I will now be focusing on adding the remaining electronics and functions. Once the electronics are complete I can then start on the detail aspect of the build which shouldn't take too long. More progress to come!