Not sure which is longer. How long it's been since I was a regular poster in this forum or the last time I built a 1/4 scale aircraft. Got a feeling there is a direct correlation there somewhere.

The little 144th F-4 was the germ that caused the fever. More cowbell won’t help this one but a 1/49 109 will.

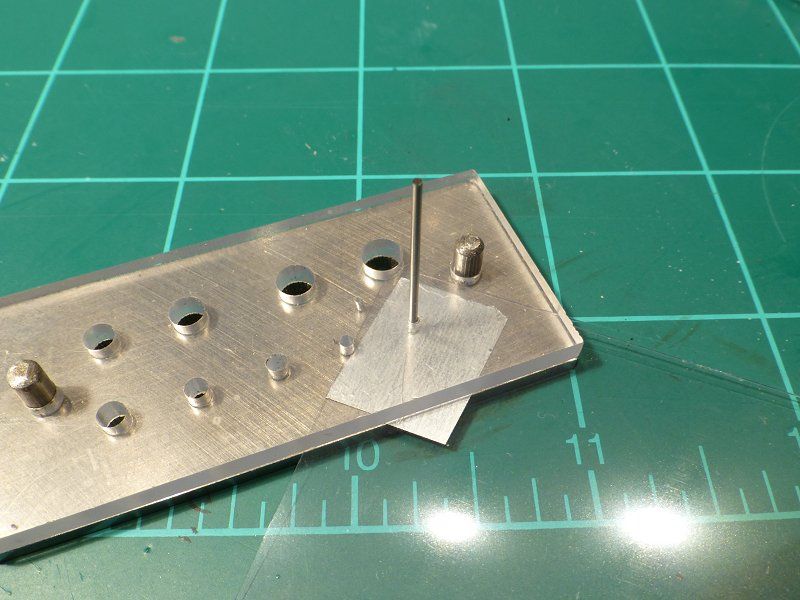

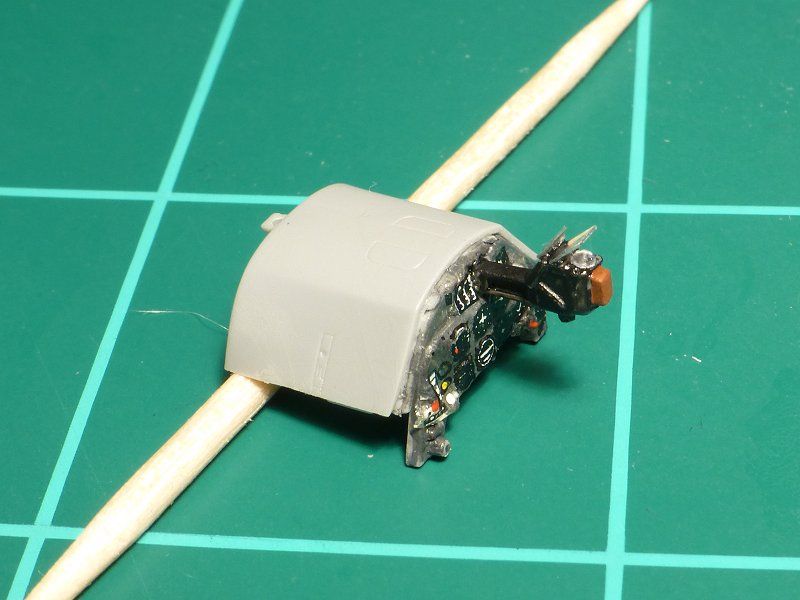

I have to agree with the reviews i read saying one of the few weak points in this kit is the IP. But I have decided to go with a buttoned up canopy, getting the instrument decal to settle over the IP is too bad looking and will be fine under the glass. I applied a piece of Bare Metal Foil on a very thin piece of acetate and punched a small circle to represent the lens in the gun sight, then used the same stuff to make the reflectors.

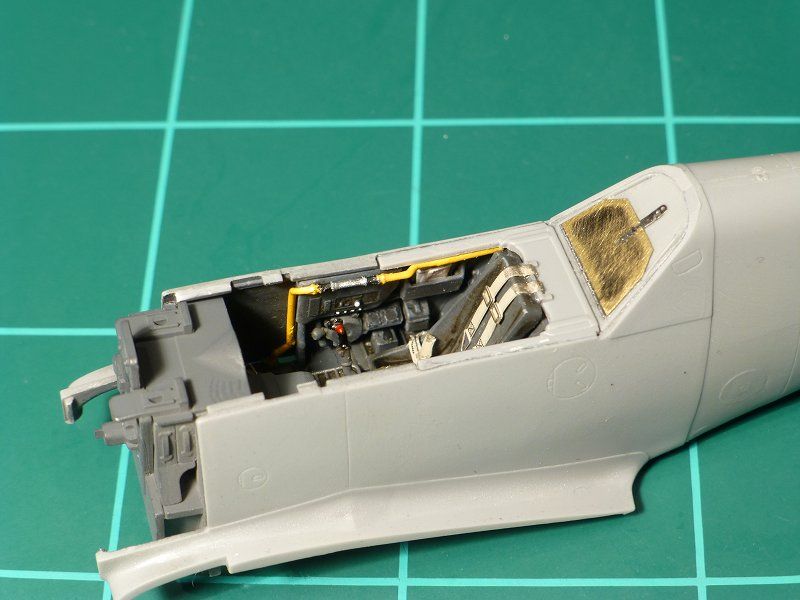

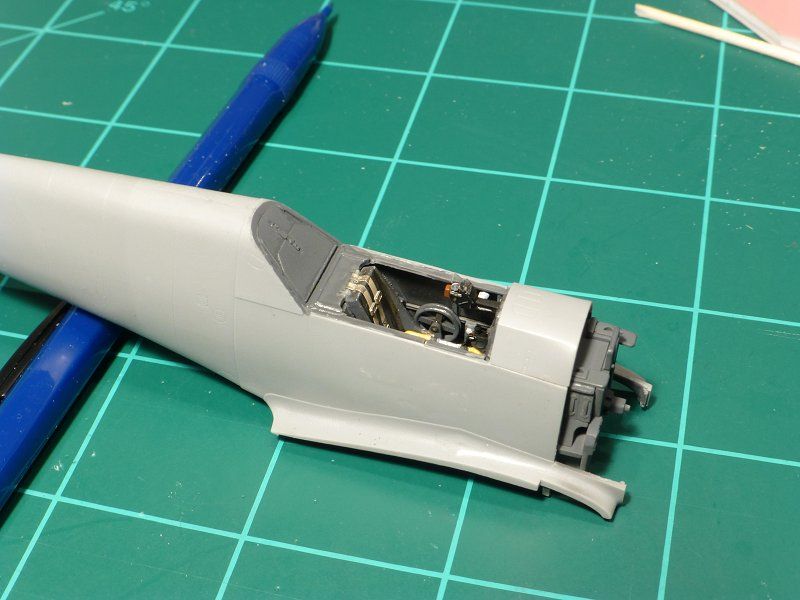

With the IP done and glued into its little section of the cowl, the fuselage halves were joined. I don't have a photo of the tail but Zvezda went with a 4 piece empennage with the 2 sides and the tail in 2 pieces. This is usual done for future kits to have different tails. Fine. I get it. But I have yet to have one of these go together without a lot of adjusting to get the best fit you can but then still having some sanding to do to remove a small step or something else. They also opted to make this fall on one of the very distinctive panel line features on a 109s. The vertical lines spaced down the length of the fuselage.

Note the the manufactures that may be reading this... STOP THAT!  Make the seam in the middle of 2 sections. Way easier to fill, file and clean up that line and leave the pre-scribed panel line intact. That was we don't have to try to rescribe that line around the circumference of a tapering fuselage. And scribing over a glued line is always harder not matter how long it cures.

Make the seam in the middle of 2 sections. Way easier to fill, file and clean up that line and leave the pre-scribed panel line intact. That was we don't have to try to rescribe that line around the circumference of a tapering fuselage. And scribing over a glued line is always harder not matter how long it cures.

PHEW! Sorry for the rant. But I do feel better now. :P

Cockpit pics... PE belts & storage compartment door are from an ancient Eduard set I found at the bottom of a drawer. It pays to be a pack rat.

The engine is a real beauty and with some wiring and piping can be a real looker. But I've decided to go all buttoned up to take atvantage of the gorgeous line of the F series... the best in breed.

And its as big as a whole 109