XB-70 Valkyrie (AMT kit #8907 in 1/72 scale): This is NOT a kit for beginners, nor would I recommend it for someone without significant patience. It is however a truly beautiful model with striking dimensions (length about 32” and, depending on wing configuration, width up to about 17”). I wasn’t planning to share these photos, but decided that someone might benefit from my mistakes. I tried to improve the photo quality, reduce the background clutter and compensate for poor lighting with photo tools and cropping. As this build continues hopefully I can improve both my lighting and photography skills.

Fuselage Assembly: The fuselage came in four pieces. The sequence in the instructions, which I followed, was to join the forward halves together and let them dry. Then join the aft halves together and to the completed forward section at the same time. The sides matched adequately with some minor filling and sanding. But, the mating between fore and aft was very poor, needing much filling and sanding. It might have been better to join the fore and aft pieces of each side together first and then join the two resulting halves. But, either way it caused a problem when mating the fuselage to the wing assembly. I describe that later.

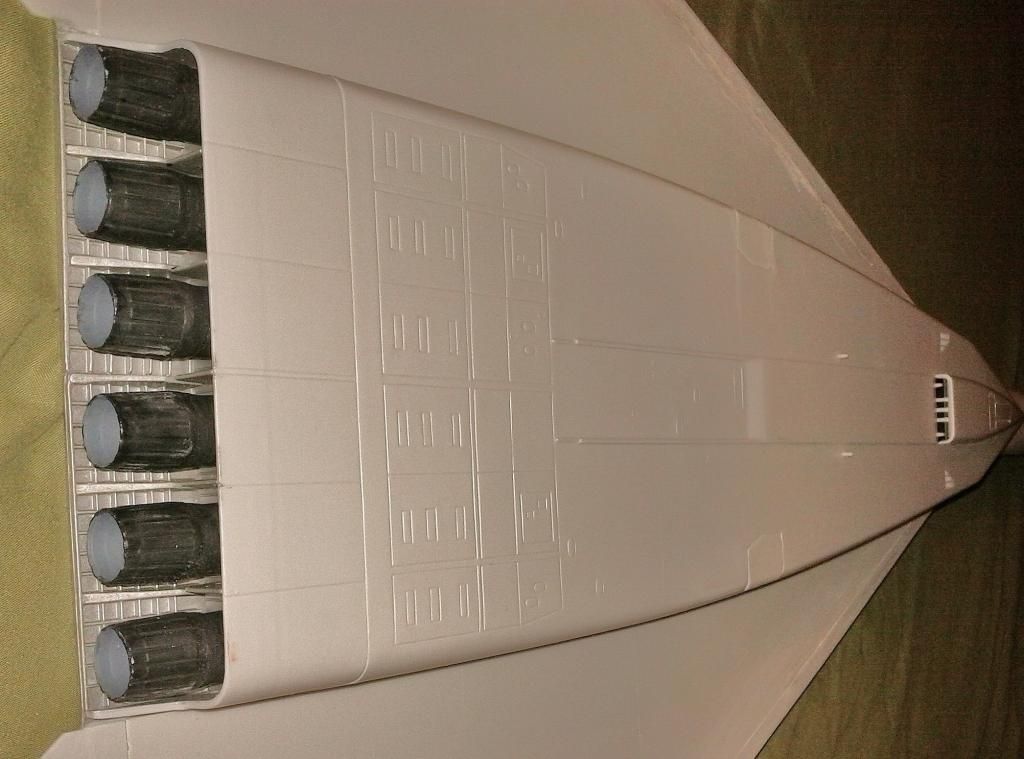

Wings and Engine Bay Assembly: The upper and lower wing parts fit poorly and required much filling and sanding. The engine bay assembly, however, went together well and quickly. It mated easily with the wing assembly but did require some filling and sanding.

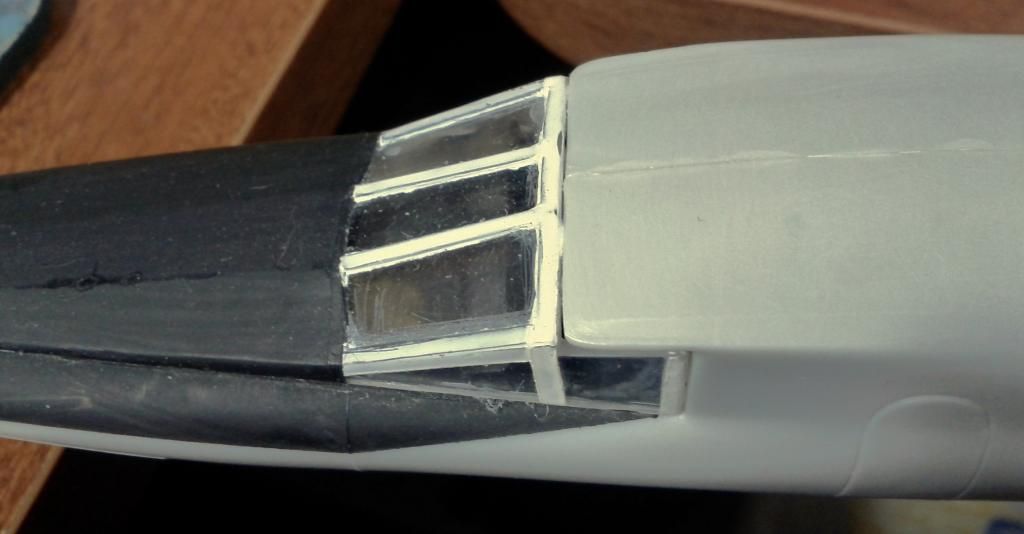

Six Pack” Engine Bay Assembly: Simple assembly and fit was good. I hand brushed Testor “small bottle” enamels: “Flat Steel” in the areas surrounding the engines, “Flat Black” on the engine exterior and mixed “Flat Black” and “Flat Gray” for the engine interior. The photo makes the interior appear much lighter than it really is. I still have some work to do on the engines, including “aging” on and around the engines.

Stabilizer Control “Fingers”: The control fingers were separated for about a quarter inch out of the box. I used a razor saw to lengthen the separation. What appears as a hinge line in the photo is actually the seam between the upper and lower wing halves and will be filled and sanded away.

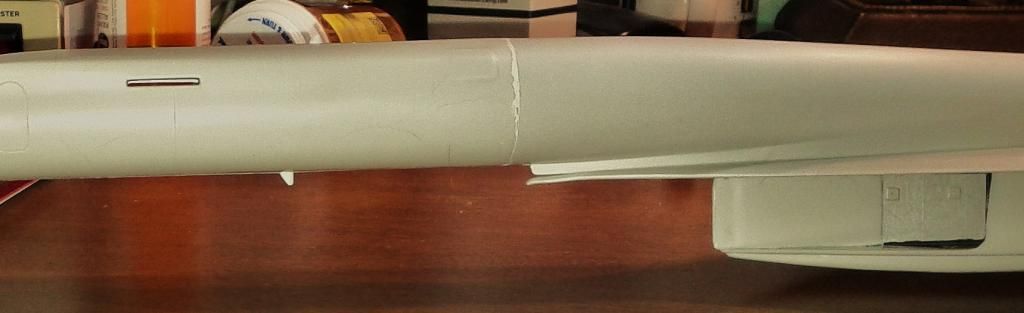

Mating Wings To Fuselage: At best, the fit was poor. You can see just ahead of the air intake that work is needed in a difficult position. This, however, is just the beginning…

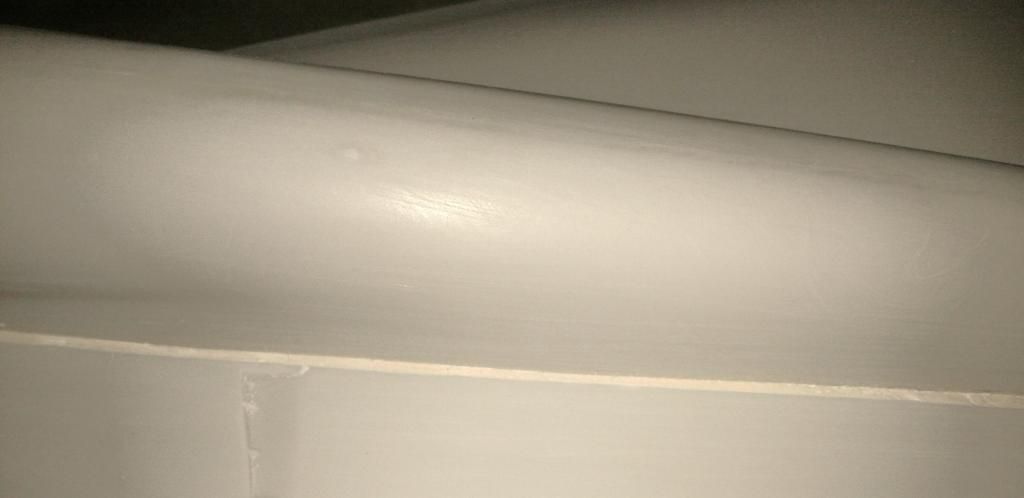

The seam between the fore and aft fuselage assemblies is particularly noticeable in this view.

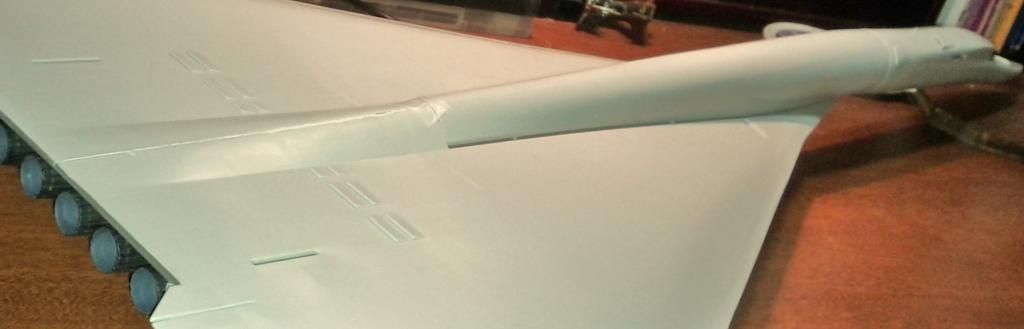

A wing to fuselage test fit revealed about a 1/16th inch gap between the fuselage and the wings to contend with. Much filling and sanding was required and I’m still working on it. In retrospect, I think the gap could have been made significantly less by attaching the fuselage to the wings at the same time as gluing the fuselage halves together. At that point, while the aft fuselage glue was still soft, pressure applied from the top forcing downward might have flattened and widened it forcing both the fuselage halves together and against the wings. The clamping would have been tricky, but I think it would work.

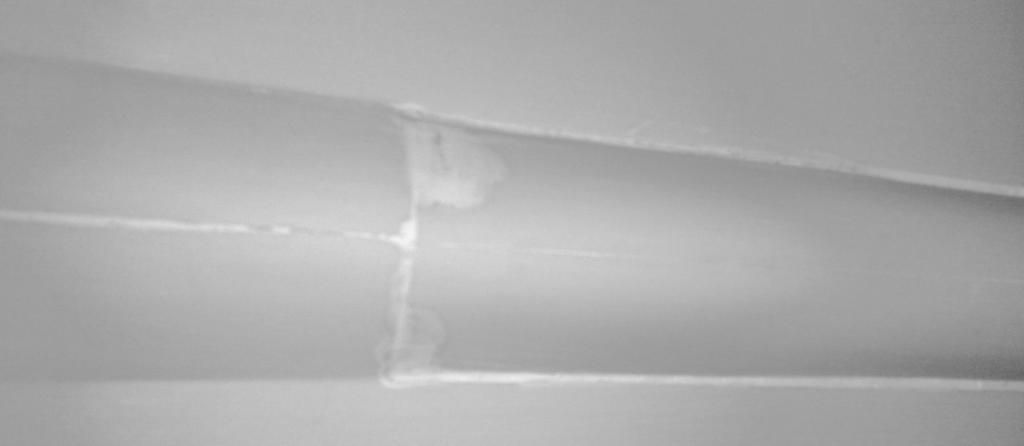

Where the fuselage joined the aft part of the wing surface the fit was terrible. Again much filling and sanding needed and, frankly, I’m still not satisfied with it. Hopefully it will disappear when I eventually apply the primer. But, at this point it just doesn’t feel right to the touch.

Another view of the wing to fuselage gap and the filling/sanding in progress.

Air Intake Area: View of the lower wing just ahead of the air intakes. Filling and sanding in progress…

As you can clearly see, considerable filling and sanding is required on the wing undersurface and the air intake area. The enormous amount of wing surface translates to literally hours of sanding.

Some filling and sanding needed on the air intake.

Cockpit Area: I made the mistake of getting in a hurry to begin some of the painting and hand painted the anti-glare panels on the nose. I’ll have to sand down and use my airbrush to get a better look.

This is definitely a kit on which you can really practice your filling and sanding techniques!

This is where I am today. As you’ve seen from the photos above, I still have much filling and sanding before it’s ready for primer. The assembly, however, is pretty much done. All that’s left are the wing tip assemblies, canards and vertical stabilizers to be attached after painting.

I must admit that I’ve been dragging my feet with the filling and sanding because painting something this size intimidates me, especially in gloss white. FSM forums comments suggest that “rattle cans” would be best for something this size. I guess that’s sound advice, but I haven’t had great success with them in the past. I guess I need to practice a good bit doing multiple thin coats alternating between lengthwise and crosswise spray patterns. Thanks for “listening” and I welcome your feedback.