Work is still progressing on the transom and quarter gallery work, though slowly. I've been focusing on translating the curve/bulge of the transom into my model, and, while I've made progress, I'm at the point where I could use some advice from more experience members.

First, here's a shot of a drawing from the Lavery/Hunt book, The Frigate Surprise. To respect their copyrighted work, I've zoomed in pretty tight:

It was fairly easy to use a compass to capture and scale up the curve to my kit. In the meantime, in looking at pictures of the HMS Surprise (Rose) used in the Aubrey/Maturin film, I noted some structural differences between it and the Lindberg kit. First, here's a reprise of the (trimmed-down) kit piece:

Here's a look at the San Diego Surprise:

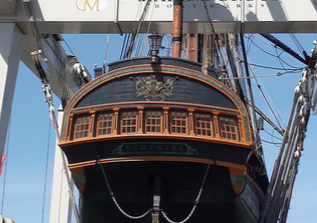

And, after looking and looking for months now, I finally found a shot from pretty much dead abaft:

So, you'll notice that the assembly below the stern windows extends further out to each side, and the concave curve it exhibits is translated forward, to sit underneath the quarter galleries (just like crown moulding in a house). Also, there are korbels (is the right tern in this instance?) underneath all of that, which also translate "around the corner" to ride underneath the quarter galleries.

I've been experimenting with how to best migrate all of this into my model, and after first thinking I would use a build-up and file approach, I've decided--at least for now--to lay in two pieces of sheet styrene to set the upper and lower curve, and then perhaps fill in. Let me post a couple of shots, and then I'll ask my questions:

Here's what it looks like from underneath-ish:

From a bit more head-on:

You can see where I played around with building up from this angle, i.e., those two chunks of styrene strip.

So, my quick question is this--does this look like the right track? If so, my main question is--what is best way to create the actual surface that sits between the two pieces of sheet styrene? It will need to be curved in both the horizontal and vertical planes, and exhibit a slight but noticeable concave curve. I'm tempted to just lay in Tamiya putty, and mold with a wet finger, just like caulking a tub, but I'm worried that the presence of so much solvent will just dissolve everything.

I also have a few runs of Bluejacket's tiniest basswood strips, so I'm open to the notion of laying these in over a framework of some sort, but that may be too much of a muchness.

FYI, the corresponding surfaces underneath the quarter galleries will be fairly easy, I believe, since they're fundamentally straight. I've already created a laminated unit using two pieces of sheet styrene glued up and taped around a pencil that I believe will answer admirably.

Thoughts? I'd love some help!

Charles