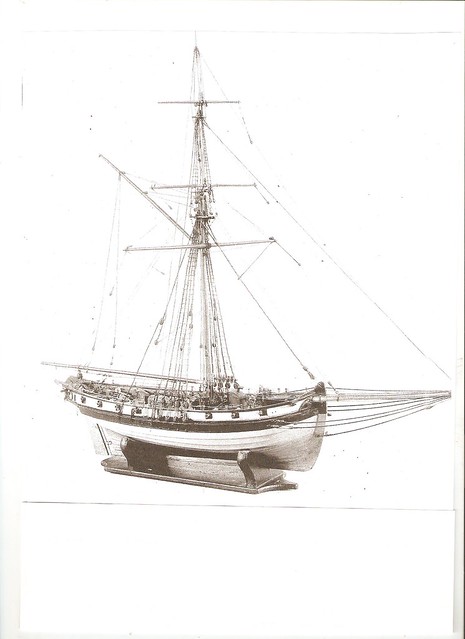

INTRODUCTION History and development of the British revenue cutter.

It is believed the single masted cutter originated from the Dutch during the early part of the seventeen century. These yatchs were designed for use in the shallow costal waters with a simple single mast with a main sail. About 1650, the addition of head sails proved to be an advantage for sailing closer to the wind. Soon, these sails were supplemented by a jib on a jibboom which could be removed. This sail came to be known as a "bezaan" sail. A vessel of this sort was presented to king Charles II while in exile in Hollard. Upon his restoration to the English monarchy in 1661, the "bezan yacht" became a popular royal sailing activity. Later, the bezan yachts in modified form became a standard scouting and advice craft for the Royal Navy.

The collection of import taxes and the supression of smuggling to avoid these taxes had been a duty of the royal crown since king John (reigned 1199-1216). In 1699, by Royal Proclamation "Revenue,Customs and Excise" became a seperate entity from the navy. At this time, this service became interested in using cutters to supress smuggling. By the 1750s, the design of the cutters evolved to be like the DILIGENCE. The cutters were constructed mostly in private ship yards at Folkstone, Dover and Shoreham. Thus, documentary evidence of construction, unlike the Royal Navy ships, is scarce and fragmentary. Cutter construction of the hull was mostly clinker built with planking attached to light frames, and armed with 4 pound guns. The cutter's strength and speed is owed to this type of construction. On average, the cutters were 70 feet on deck, 24 feet beam, 11 feet depth of hold and about 161 tons burden.

During the Seven Years War (1756-1763), up to the conclusion of the Napoleonic conflict that ended in 1815, smuggling attained epic proportions to bypass the British blockaid with France. Many Kentish and Sussex towns on the English east coast became smuggling centers of this illicit trade. In retalation, the revenue cutter attained its "golden age" of design and function. The date of the DILLIGENCE is about 1810. These cutters were often crewed by a hard bitten lot of ex-smugglers and fishermen, who knew the ways and strategies of active smugglers. It was a case of using fire to fight fire. After 1815, cutters were heaver built with greater armament, which cut down on the speed and maneuverability.

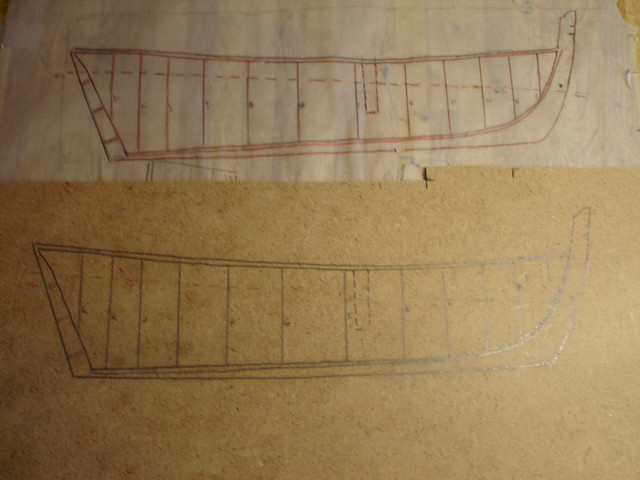

The plan for the construction of the DILIGENCE cutter at 3/16 scale was drawn on September 1947 for the now defunked Marine Model Company of Halesite, Long Island, New York. It was bought some time during the 1950s. The blue print background is so old that the plan was starting to fall apart at the seams and held together with the adhesion of Scotch tape. Only by carefully placing the plan on a secure flat surface could tracing outline on different parts of the model could be achieved.

With the help of tracing paper, the hull was copied on partical board, making sure the section lines that were lettered A, B, C forward and numbered 1,2,3, aft from the midship section in an attempt to create a three dimensional hull on a piece of two demensional paper. These stations on the starboard side of the particle board were drilled with small vertical holes to make sure the section lines on the starboard side would agree on the port side when cut out.

Here is the cut out profile of hull that will hold the starboard side bulkheads. The small vertical holes drilled in the bulkhead slots are a reference point for port bulkheads when glued on the port side of the model. The same is true for the placement of the lower planking. The open slot midship, is where the single mast is to be centered.

Starboard side bulkheads have been glued in place. The hull planking is yet to follow.

Pieces of balsa wood were inserted and glued between the bulkheads and sanded to the shape of the hull. Balsa wood was chosen because it is easy to sand and shape to the correct contour of the hull. This solid filling will give more adhesion surface for the hull planking in clinker fashion.

Here is the first stages of clinker planking of the cutter hull. Clinker planking is where longitudinal strips of planks overlap, with the higher plank always overlapping the lower plank. This system of planking evolved during the Viking era on their long ships that terrorized Europe. Strips of thin wood was first tried with frustrating results of splinting and breaking on the DILIGENCE hull. Cutting strips of cardboard from a discarded cerial box achieved better results. The cardboard was easier to shape and adheared easier to the balsa filler between the bulkheads.

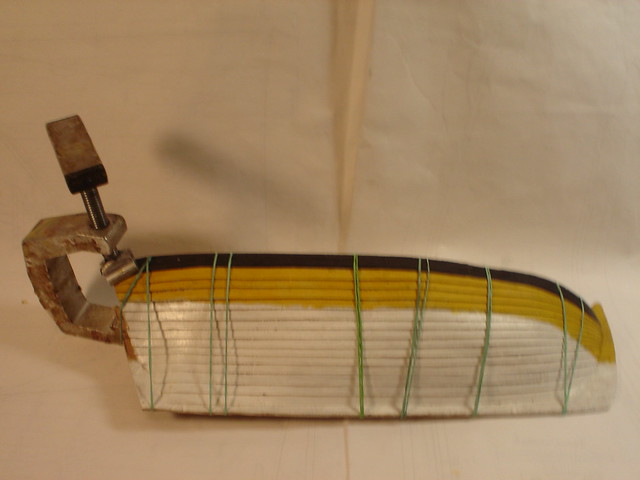

The hull partically completed and deck planks added that were cut from popsicle sticks. The whole arrangement to held together with elastic bands while the glue dries. The wale is to be added later.

Clinker planking has been finished on the starboard side of the hull. The clamp is holding the black painted wale in place . The white tallow bottom of the hull has been painted with acrylic paint, while the upper section has the yellow ochre acrylic color, common on British ships of that time.

The clock on the wall tells me it's bedtime. Will continue later. Happy modeling Crackers