I was really unhappy gluing the floater net baskets (FNBs) directly to the ship's handrails. They were popping off as fast as I could get them on, and it took way too long to what essentially was a simple task. I did wrestle all the FNBs that were shown in my broadside picture of the actual ship, but wanted to find a more secure method.

I woke up this morning thinking about gluing the FNBs to foil and then wrapping the foil over the rail and gluing it to itself making essentially a sandwich with foil as the bread and the rail as the bologna. The foil I was using is wine bottle seal foil which has some body and I use it for all sorts of detail work. I first tried Microscale's foil adhesive, but it didn't have enough strength in such a small surface area. That left me doing it with thick CA.

I measured both the amount of foil needed for the FNB interface and then the depth of foil that would fold over the rail. I cut off a strip and measured the width of one FNB, and folded it in my PE folding tool so the fold was nice and square. I glued the high side of the FNB to the foil and then glued this assembly to the rail. Here is the foil measured to hold four FNBs together. This also made gluing mulitples easier... not a lot easier, but easier all the same.

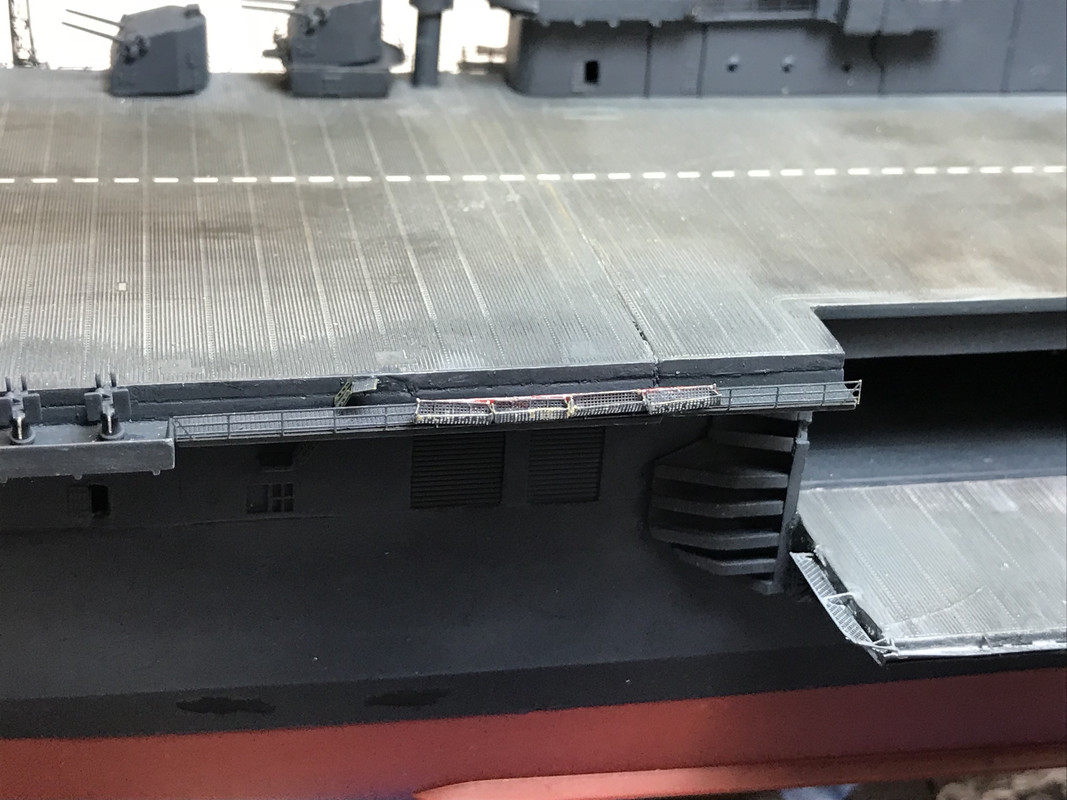

The idea actually worked, and the connection between the FNB and foil, and the foil to the rail was much, much stronger. I glued up singles, doubles and four-in-a-row and completed the entire port side. I toyed with the idea to remove the starboard side's FNBs and redo them with this method, but decided against it leaving well enough alone. So there is a visual difference between the two sides. I surmised that going back and attempting removal would result in some rails coming loose and I didn't want to deal with that.

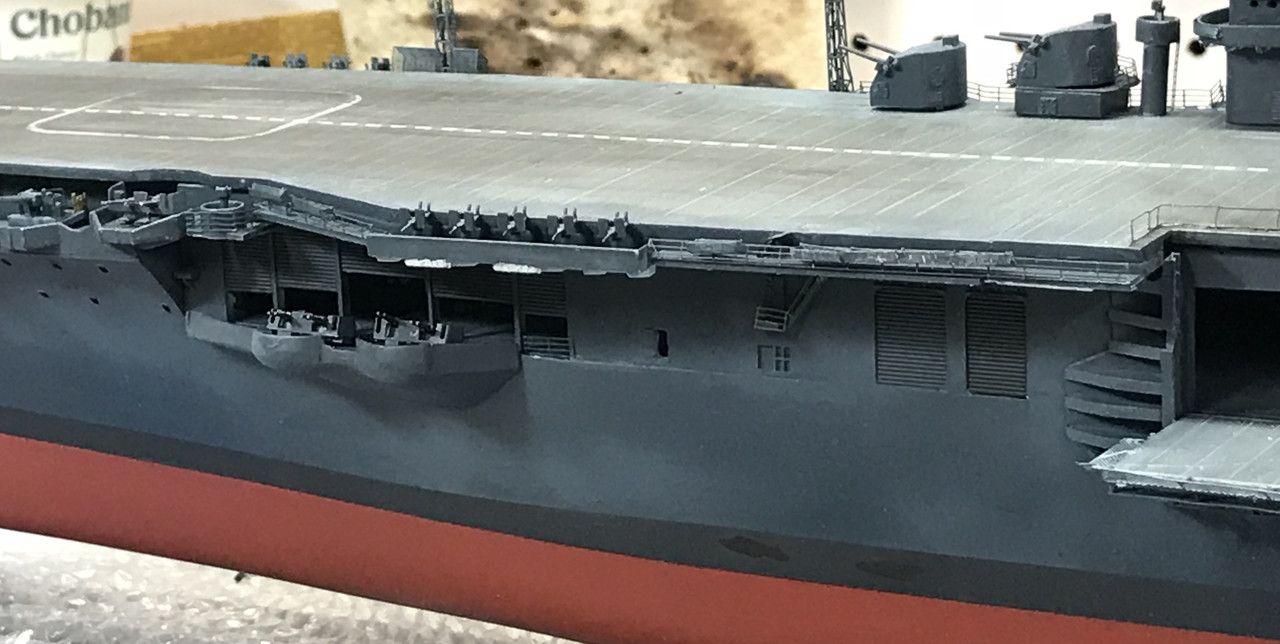

On the starboard side I attempted to brush paint Navy Blue to clean up all the mess, but this resulted in some FNBs falling off creating more mess. So I stopped that and decided that I would airbrush all of them when finished. I did some selective masking to keep the spray off the flight deck and did the touch up painting. But, before doing this I did add the two tiny missing railings buried in the port side; one to the boat deck and the other on a ladder platform next to an access manway. You can see this railing in the below.

This reverse angle view shows what you can see of the foil. I think it's a decent solution to an annoying problem and, while not prototypical (I actually don't have a clue how the FNBs were hung from the rails) it does not look too obtrusive and at least the port side's FNBs won't fall off. Can't say the same for the starboard's. I would think that the real ship probably had some form of framing behind the baskets that actually tied them to the ship. I can imagine that they would be quite heavy especially if awash in seawater spray.

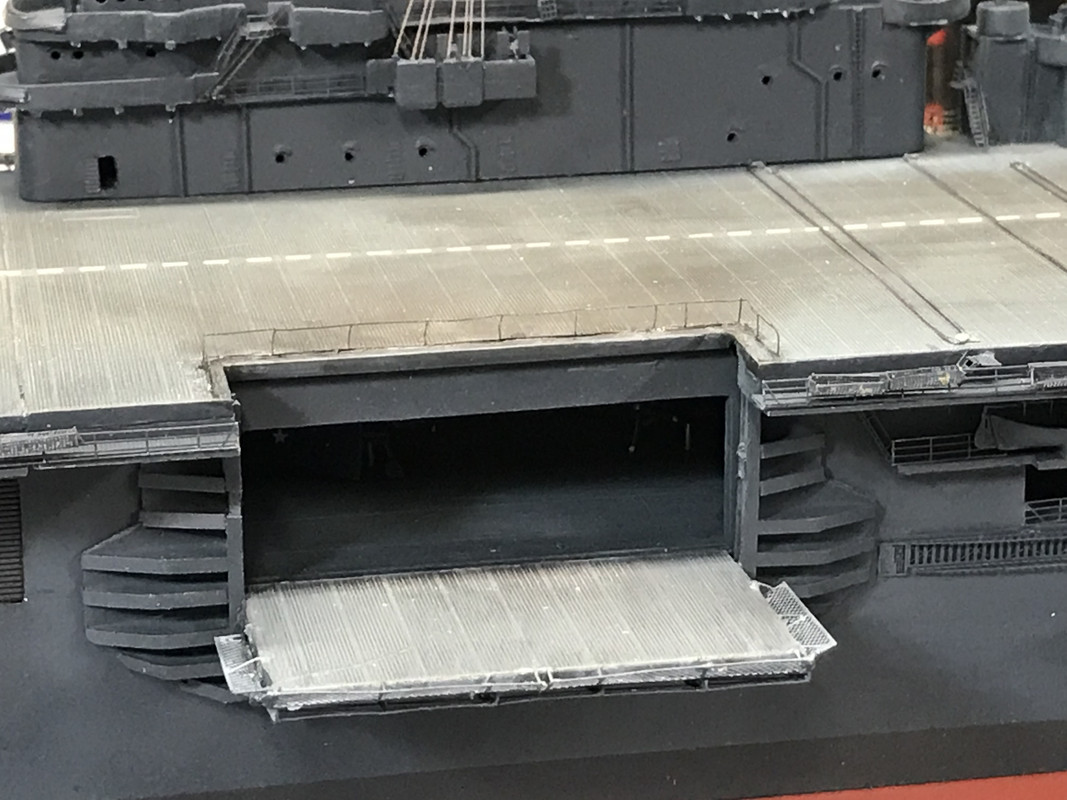

The last thing I did today was locate a single bar railing and put it on the FD to guard the elevator opening. This railing was pretty messed up and I fiddled with it until I had a stretch of railing that would cover the distance. Again, it's not really pretty, but it works. The other method would have been to drill the deck, use some guitar string rods for stanchions and string it with E-Z Line, or fine copper wire. My first choice worked. In this image you can also see the small rail on the boat deck on the right side of the picture.

I really not happy with the whole FNB exercise. I don't like how they come out when folded and glued since there's a lot of variation between them. And as careful as I tried to be, they're sitting at all kinds of angles and don't look very shipshape. I thought about leaving them off, by AMS set in and I was compelled to do it.

What's left? Putting on some end-of-catwalk railings which are simulated with a chain top string, and then rigging the long-range radio antennas. Finally, putting the planes on deck. A very fine modeler, David Koeleiski, says he glues his with CA. I suppose that's how I'm going to have to do it too.

The plexiglass should be getitng here soon. General Plastics and Rubber's router broke and the part was supposd to arrive yesterday. My work is on the top of list. Regardless, I have a Ford GTA to finish and a half-built structure for the railroad, so I won't get bored waiting.