Last year after researching the various booths out there I decided to build my own. I got a much larger booth for $200 than I could have buying someone elses booth, and it has a higher air flow than most of the ones you can buy, most of the cost was the fan.

I bought the fan from Grainger, I'm not a commercial user and I had no problem, I just listed my name where it said company. Awesome service too, I had my fan within 24 hours of ordering it. If you do get a fan from Grainger make sure you also get a cord, the blowers assume they are going into a furnace or other built in set up. An 8 foot cord is only $6 or so and is pretty simple to wire in.

If you have the skills (did you pass 9th grade wood shop?) and the time I would suggest building your own. It will save you a lot of money and you can tweek it to your own preferances. For example I set mine up with a more open top than most, because I'm using spray cans and prefer to paint downward. I've got it set up where I can close down the top if I don't need so much room which will also increase the airflow at the face since the opening will be smaller.

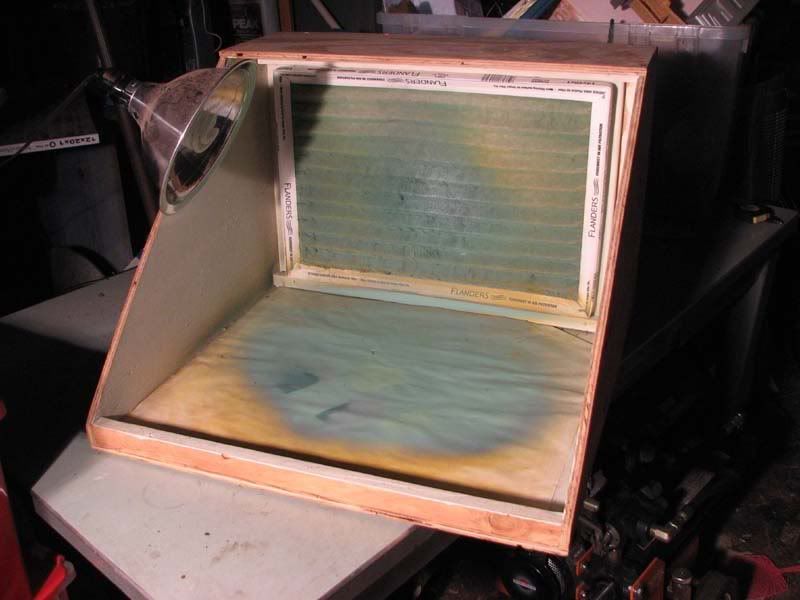

This is what I built, 24" wide, 20" deep, 20" tall with a 485 CFM squirrel cage providing more than the 100 fpm at the face most sources recommend. Big enough to handle a 1/72 B-17 or 1/25 semi truck. It does a nice job sucking the paint fumes outside. It is sitting on a table now, because a stupid bear broke into the garage and busted up the stand it was sitting on. It took me about 2 days of work and just under $200, the fan was $144..

There is no need for an "explosion proof" fan, those are intended for moving serious flammable vapors like a full size automotive spray booth or evacuating vapors from a fuel trailer before working inside. Even a small explosion proof fan would cost you around $1000. I'm not in favor of the cheap booths made with a box fan or stove hood because of the potential hazard (Smokey Bear is a close personal friend and he would beat me senseless if I said go for it  ) but would agree with Mike that the chance of a fire is very small.

) but would agree with Mike that the chance of a fire is very small.

I have seen some cheapo booth designs using a shop vac and that is bad news. While the box fans and stove hoods have an ignition source (a sparking motor), there should never be a high enough concentration of vapors to actually burn. With a shop vac the cannister will collect fumes which will build up and can have explosive results if ignited.

Mike a cigarette can ignite diesel fuel, but you would have to get it pretty hot first so it makes enough vapor to burn.

The flash point (hot enough to burn) of #2 diesel is around 125 degrees F, the flash point of gasoline is -45 F degrees. So you might get some diesel to burn with a cigarette if it was spilled on the pavement on a really hot day, but gas will burn in Alaska in the middle of december. The signage regulations don't take this into account and pretty much treat diesel as gasoline.