Hey, guys, sorry to flog a dead thread, but I have another question about the Eduard instructions.

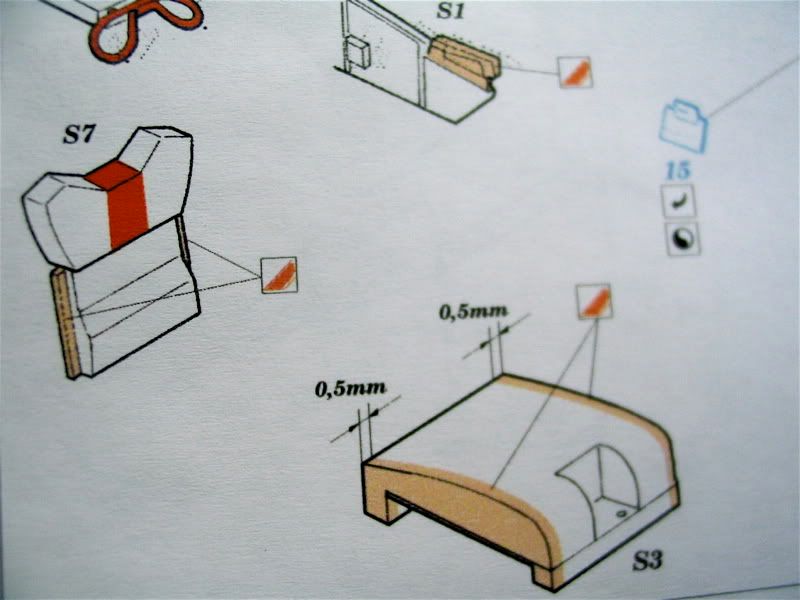

In this photo of the instructions, note that the red areas need to be removed, and the orange areas need to be ground down:

As you can see, the sides of the CQ ejection seat bottom as well as the tabs on the side of the seat back need to be ground down. According to the instructions, the seat bottom sides should be shaved .5 mm.

Why?

As far as I can tell, these modifications don't affect how you attach the PE. If anything, looks like it would make attaching the sides of the ejection seat more difficult. Is this merely for accuracy vis a vis the real seat? If so, I'll probably skip.

Thanks!

PB