This is a follow-up of my post from last year.

Conclusion: You don't need an airtank if you have a twin-piston compressor running in fine condition. If is a fun project when you finally get everything working. The picture were taken in Feb this year.

This is the DA400 compressor. It is an earlier model made in Taiwan. The output is an 1/8" BSP thread. I cannot make the NPT flare tubing adaptor leak free and ended up using three pieces to convert that to a flare 1/4" tubing.

I found a one-gallow tank from a Campbell Hausfeld compressor on Ebay for less than $10. I would love to have an aluminum tank like those used by trucker for airhorn or brake. Too expensive. The tank has a drain plug on the lower side and 2 female and 1 male opening on the upper. I plugged one and connect a check value to the other female hole. 1/4" check value was impossible to find from any tools supplier. I found one at a beer brewry supplier store.

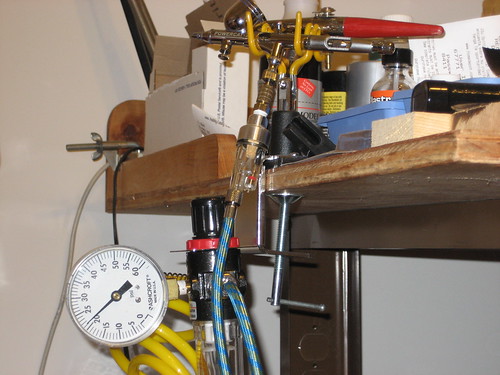

I used an air manifold for the outlet (Harbor Frieght 93979-0VGA, $2). The1/4" quick discounnt, a quick relief value for emergency and a 2.5", 100 psi scale pressure gage. It was so arranged to assure steady pressure reading unaffected by the airflow to the airbrush.

The compressor sits on a flat platform on top of the tank. A piece of flare copper tubing connect them together. I prefer the copper tubing that provide some stability. The compressor is very vibration free and does not move at all.

A 25-feet plastic tubing connects the tank to the remote regulator/moisture trap, Iwata style. I use 1/4" quick disconnect at both ends. I use the brass ones from Harbor Frieght.

I use another 2.5" gauge at the regulator with 60 psi scale. I usually airbrush between 15-30 psi. The airbrush is NOT an Iwata Custom Micro. It was a "Powercat" clone I was playing with at that time. My old Paashce H is at the background. Believe me. I do use my Iwata HP-CS most of the time.

So, here it is. My Paasche DA400 compressor with home-added airtank.