Thanks for your advice Tim and GH, but I am going with what I started. I must keep pressing on or I'll lose my gumption.

A word about applying the rivets. For many of you this is old news but for some following, maybe not.

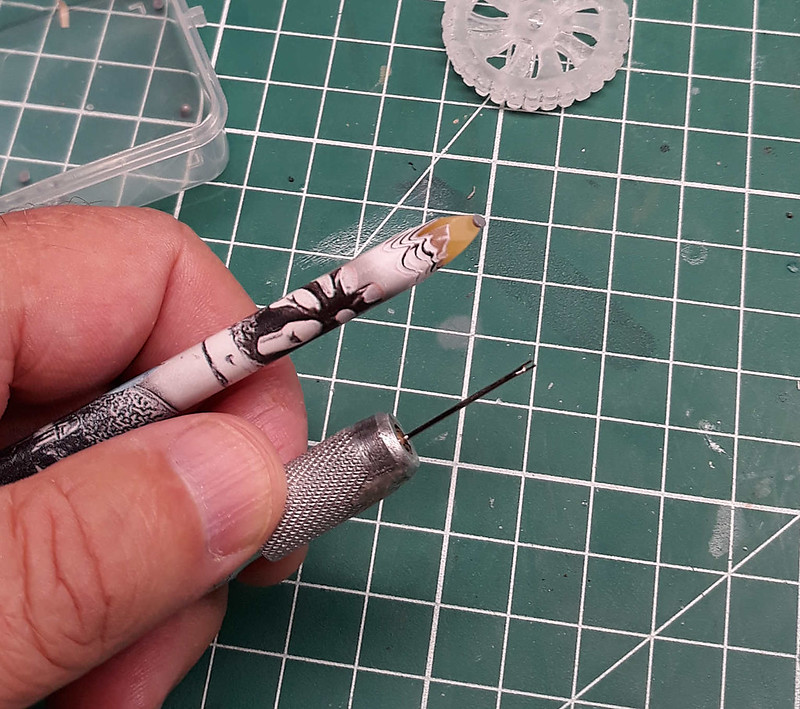

The two tools below made this job fairly easy. The wax pencil works like charm for placement. It is like the perfect tool. You lightly touch the tip to your piece, and it holds it long enough for you to place it. The amazing part is that it seems to know when to let go. You lightly touch the piece where you want it and the pencil releases it.

The second tool is a homemade jobber. I cut the eye of a sewing needle roughly in half. I use this for applying CA in precise amounts. You dip the needle in thin CA and the glue collects in the eye. Tap the needle to the piece you are gluing and the CA flows on. This is great for PE as well.

So my workflow is this: Use the pencil to postion the piece you are gluing. I then hold the piece in place with the tip of an exacto blade or other tool, then flow on the glue using the needle. Yes, I am using two hands at once. After that I use a small piece of paper towel to wick up any extra glue. It works like a charm. I also did a few where I dabbed the glue onto the piece still stuck to the pencil, then place the piece. The glue is thin, so you have a little time to position it. Then wick the excess.

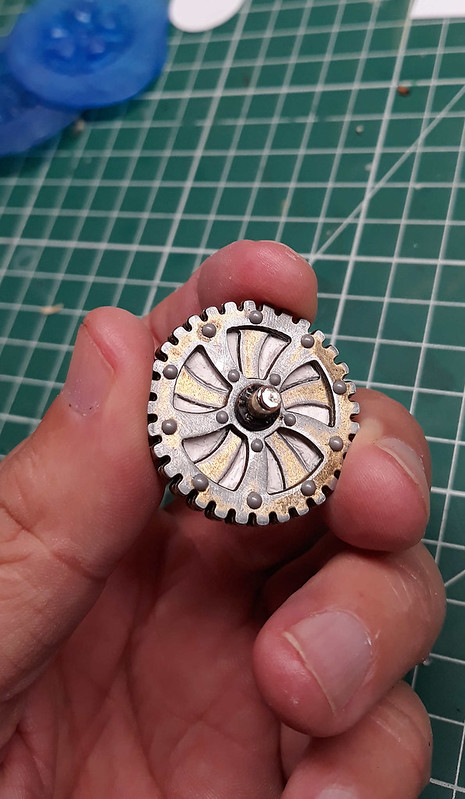

Using Sculpey polymer clay I filled in the areas that have undercuts. The mold compound requires using a clay that is non-sulfur based. Apparently, using a sulfur- based clay will affect how the mold will cure or not cure.

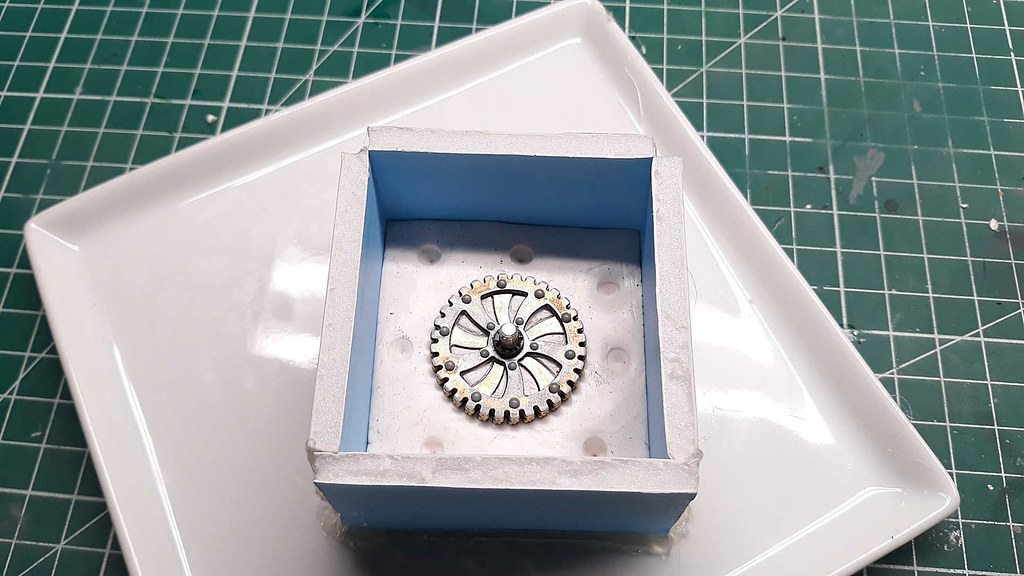

Making the base.

Making the walls using foamboard, then hot glue to seal the frame.

Needs to be mixed yet but the silicone is a 1 to 1 formula. Don't let it fool you. I was careful to pour it 1 to 1.

They say to pour the silicone in a stream allowing it to flow around and onto the piece.

And now we wait.

There was a good amount of bubbling. They say you don't need to vacuum chamber the silicone but we shall see just how clean it comes out. Most often these manufacturers make claims like this but real world the opposite is true. Which is another reason why I typically avoid casting. To do it right-- you need the right tools, vacuum chambers and pressure pots.

Anyhow-- there we go. Let's see where this side journey takes us.