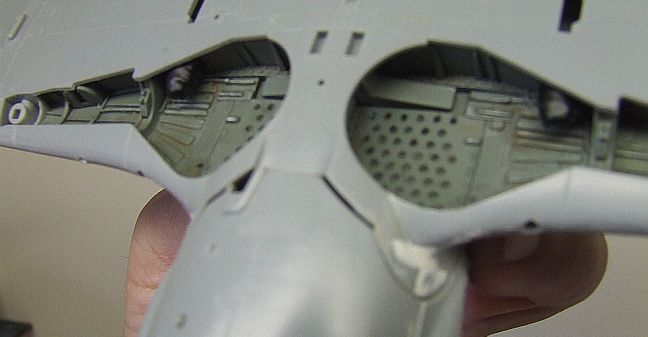

Today I did some test fitting and measuring of the gaps. Here's what I had to work with:

Quite major gaps, but when measured, little more that .020" in width. The step effect is more difficult to do something about. I started by gluing some .020" x .040" strip into the mating areas of the fuselage parts, and the intention is to file and scrape them to a contour that agrees with the corresponding parts. After that, I'm not sure, as there's really only filler work with, and the fact is that the engine housing, which is built up around the perfectly circular engine within, is simply not the same shape as the fuselage to which it is intended to join. It's too wide at about the 4 o'clock and 8 o'clock positions. I thought I might have mis-aligned the casing parts, but they are snuggly joined to each other and the engine, so I'm not sure where the problem could lie.

M/TB379