Eoin6661 wrote: Eoin6661 wrote: |

one word......superb I was wondering if you've got any step by step processes of turning that barrel?? |

|

..........and that adjective is greatly appreciated Eoin. Thank you.

However I can't help

you with one word, so......

As you know, it's been said that a picture is worth a thousand words or two or three.

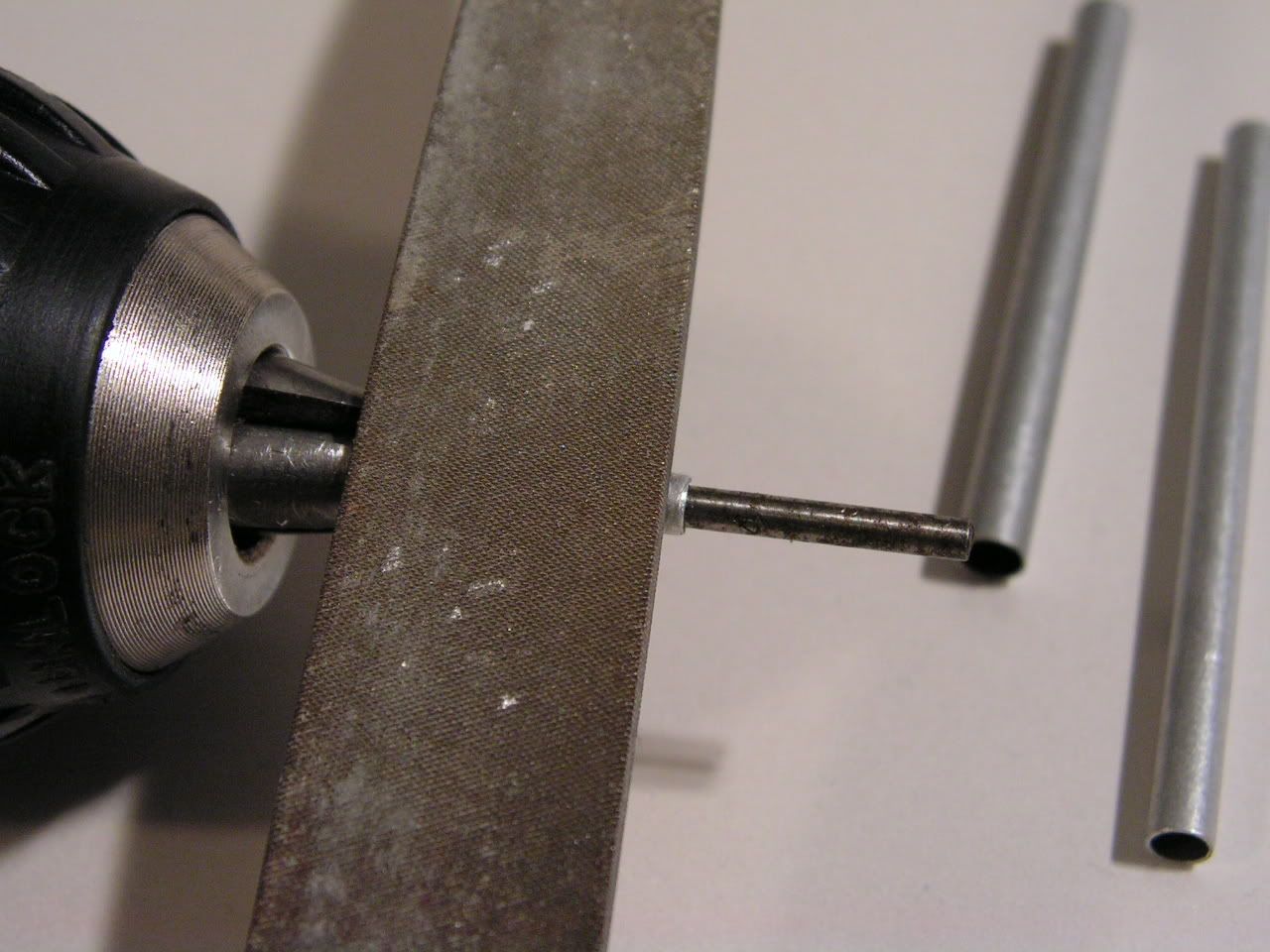

Here's my poor mans lathe....battery powered at that. A corded drill is too fast. A simple project.

For this mini-project, get some tube aluminum like what you see in those plastic bags of assorted brass & aluminum tubing. Pick three pieces that will telescope together by measuring the kit part.

So, here I am at the kitchen sink........ this should take about 30 mins once you get everything together.

For the shorter tubes, pre-cut (if needed) to the general length and put a drill bit that fits accurately (sharp end toward

backwards the drill) inside the tube you need to cut off and place it in the drill chuck. You don't have to tighten this 'till your teeth shatter either. This reinforces the tube from distorting and bending. Get your razor saw (that sucker will slice you) and place against the chuck (it's hardened steel) in place of the file as shown in the above picture. Crank up the drill, hold the saw carefully and cut it about a 1/16 longer than you need using the jaws of the drill as your saw support. You'll easily cut through the aluminum but not the hardened drill bit. Next, lay the file against the end of the cut right on the drill bit shaft and file it on down that last 1/16 or so as the drill spins.

For the muzzle, well the pic pretty much says it all. This will give you a uniform lip. All you have to do now is apply more pressure toward the end to get the taper. Stop occasionally and eyeball it to see how you're going. If the lip looks too thick, just use the file to wear it down a bit. Since it's telescoping you can adjust the length when you install it. While it's spinning in that drill, use some scotch brite or fine steel wool to polish/finish it up. I used liquid superglue to assemble the tubing and only had to press it into the mantlet with a tight finish . Make sure to take into account how far this completed unit will fit into the mantlet.

You can use this setup for simple barrels and save some money. Just think of all those Early Sherman and T34 aluminum barrels you can claim as your own.

Well, I hope this is clear. Thanks again!

Gotta go!

I only had about 20 minutes to work on my model yesterday.