The latest effort was aimed at the lower hull and getting ready for the track installation. First order of business was beating up the lower hull a little bit. I added some wear by stippling and dry brushing a combination of Deep Yellow, Burnt Umber, and some of the OD/Russian Armor Green mix. I also weathered up the sprockets and added some bare metal wear to the drive teeth.

Road wheels also got some wear and attention.

I installed the 6 road wheels per side but left off the idlers for now. I used liquid glue on the arms and cleaned up the long bottom run of the tracks so it could help serve as a guide to ensure all the wheels lined up together while the glue set.

While the road wheels were setting up, I turned my attention to the individual track links. At the start of the instructions they indicate that 6 of the A33 links are 'not for use', so I removed all but 6 links from the sprue and cleaned them up. They have 2 small attachment points that have to be cleaned up but that's not a big deal. I used a small ziplock baggie to hold the links until needed. The links aren't very big and I used the Optivisor during the clean-up as they don't have a large contact surface with each other and I wanted to be sure I kept as much of that intact as possible.

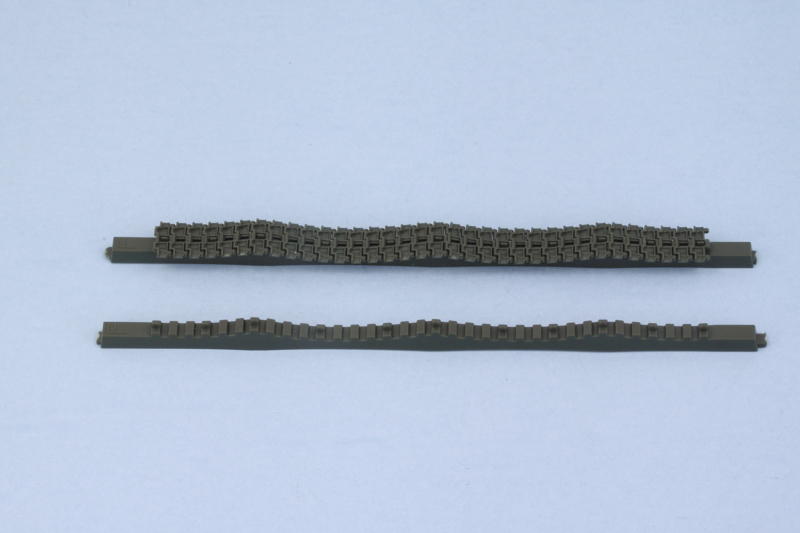

I counted out 34 links as directed in Step 19 and glued them together one at a time into a single straight run using regular glue and tweezers to fit them together. Once the run was together, I used the kit-supplied sag jig to shape the run into the necessary shape. The jig is also plastic, so care is needed in the gluing process so that the run can be safely removed after the glue has set.

The jigs also have an 'F' mark that is supposed to be the front of the run. I noticed after I took the pic that I had the run ends reversed relative to the F, so I swapped it around before the glue had set. I'm not sure that it really matters all that much but better to be safe than sorry! I also double checked the 'hump' in the sag with three of the return rollers on the left side and everything lined up perfectly there too.

I'll let the two sagged top runs set up overnight before addressing the curved runs that connect the top and bottom runs together. All told, the instructions call for a combined 63 individual links to create the tracks runs so that's a total of 126 links between the two sides not including the straight length run already provided.