The weather/temperatures up in this neck o' the north woods keeps me out of the garage for my clear coat airbrushing tests, so I'm stuck with chasing build details.

Seemed like a good idea at the time... the oval Busrch exhaust tip got under my skin somehow, especially when I measured it and upconverted it to 1:1 size; seems too large to "be real", so I'm persuing a twin tip arragement instead.

Background: When I was seventeen I bought and installed an EMPI glasspack muffler on my original 64 Beetle. I was in the process with the rear end jacked up in the driveway when my Dad came home from work, and boy did I get a scolding! I was convinced that it added 20 HP... at least it sounded like it did, and it made my girfriend giggle whenver I stood on the gas.

So, here are my WIP mockups of a center twin tip glasspack version:

The size of exhaust tips to use and still stay within "real scale" is of concern. I'm using brass(?) material from old ballpoint pens. The larger ones upconvert to 3" OD in the real world. That's still a bit big, but look great. The smaller ones upconvert to 2.2" OD, and are closer to being realistic. Decisions, decisions...

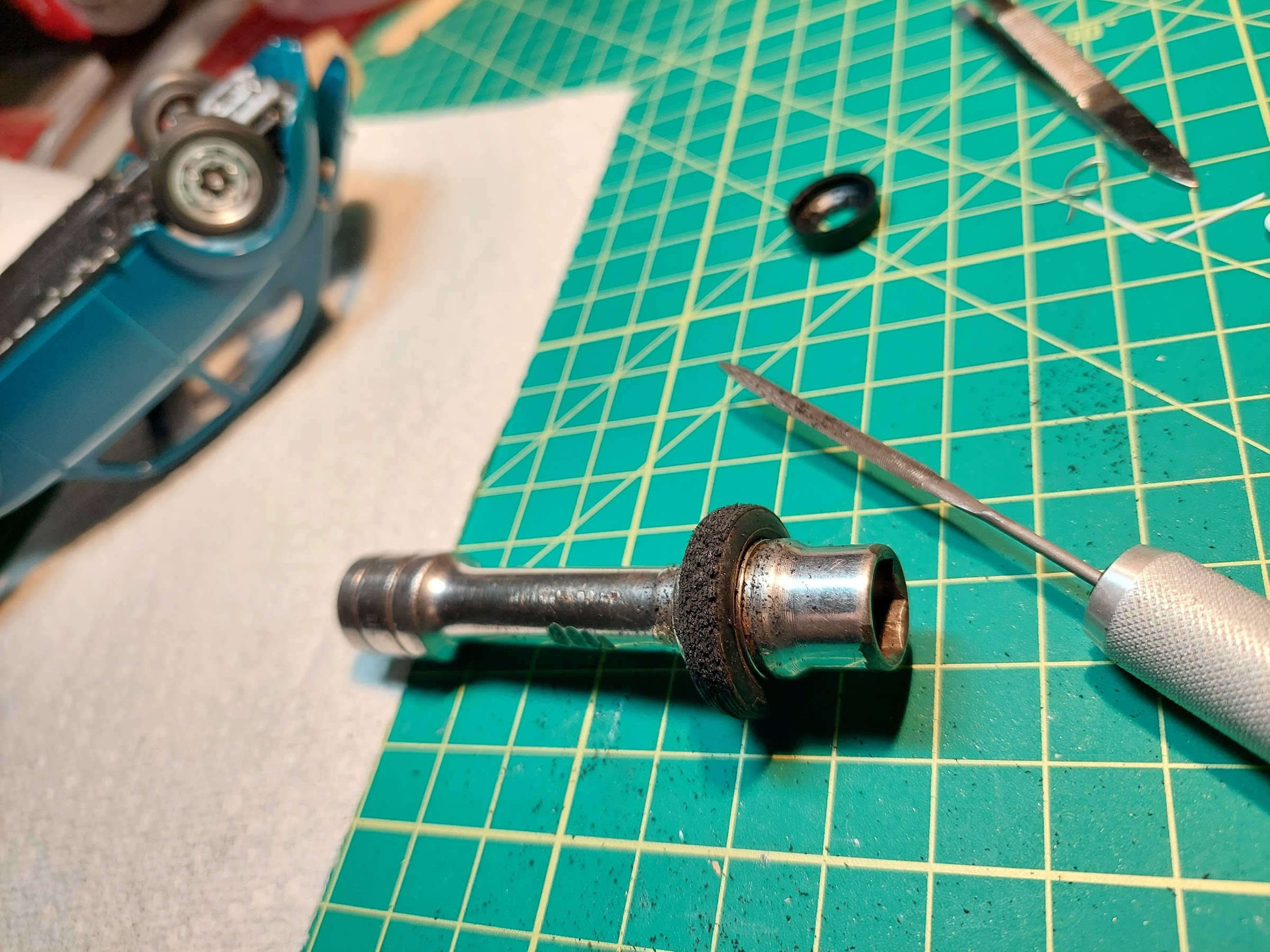

The rear license plate light enclosure needed a gasket:

Mudflaps finished:

As a starving dealer auto tech in the early 70's, I had to scrounge every penny in order to compete in my Datsun 510SSS rally car. My meager budget for consumables often meant accepting discarded gravel tires from the big budget teams. I'd often regroove a decent set of cast-off gravel tires for use as snows, so regrooving the stock Tamiya Beetle tires into gravel tires is a wierd deja-vu moment for me:

More to come.