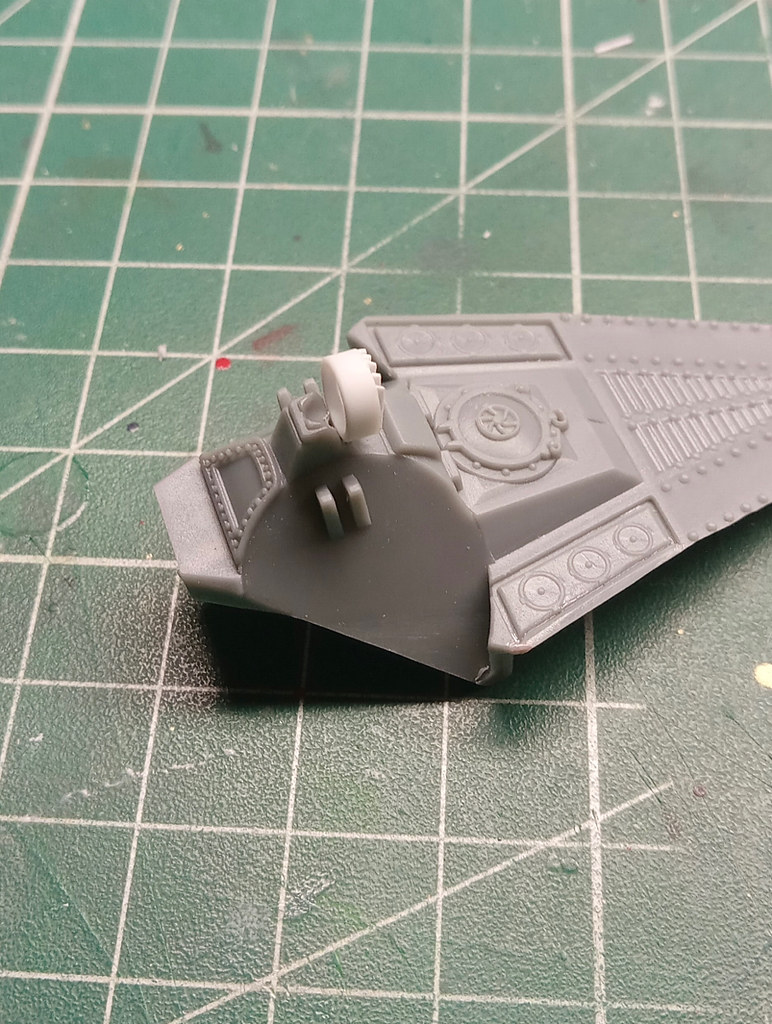

Well... mixed results on the spotlight.

I have a few small dremel bits but this job required something tiny. I had recently seen a video where drill bits are used as cutters. I gave it a whirl and it worked fantastic. A new technique is learned.

That said, the process was not without its problems. Accessing from the front, I could not fit my blade between the louvers. That left trying to cut openings from the backside, and that was not an easy task. Ultimately, I had resorted to using the cutter to try and get the plastic paper thin, then maybe, I could cut it from the back. This lead to eventual burn through. And once the drill breaks through, it catches, and drives the bit clear through. Thus, damaged louvers.

I tried to repair them using sprue-goo and with marginal success. See below. I might have been able to clean it up some once cured, but my impatience got the best of me. THAT, and when the shell of the piece cracked clean through, it sent me in a new direction.

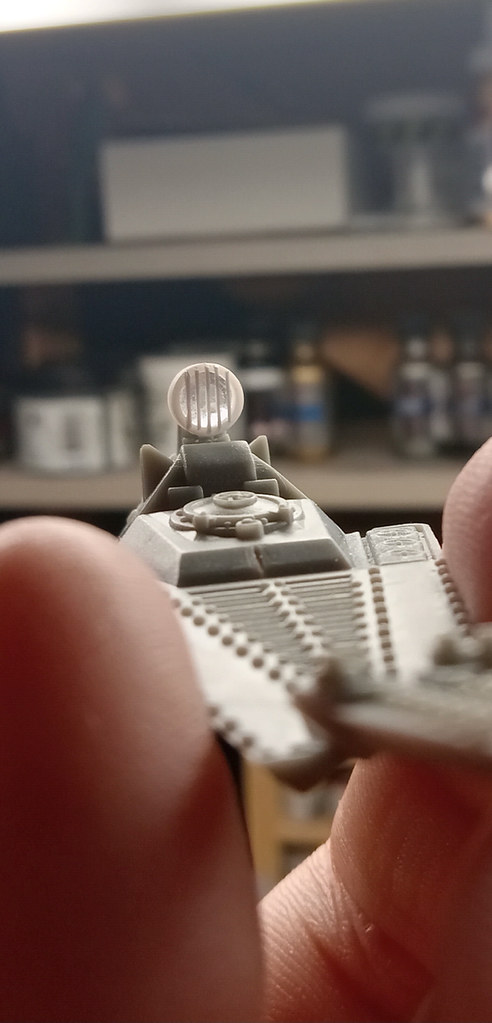

From a distance the sloppiness probably would not be seen, but I can't settle when there is a better way. I thought about doing this to begin with but I will always first try the "percieved" least path of resistance. In the end, the latter is the least path of resistance. And what is the latter? The latter is to scratch build it.

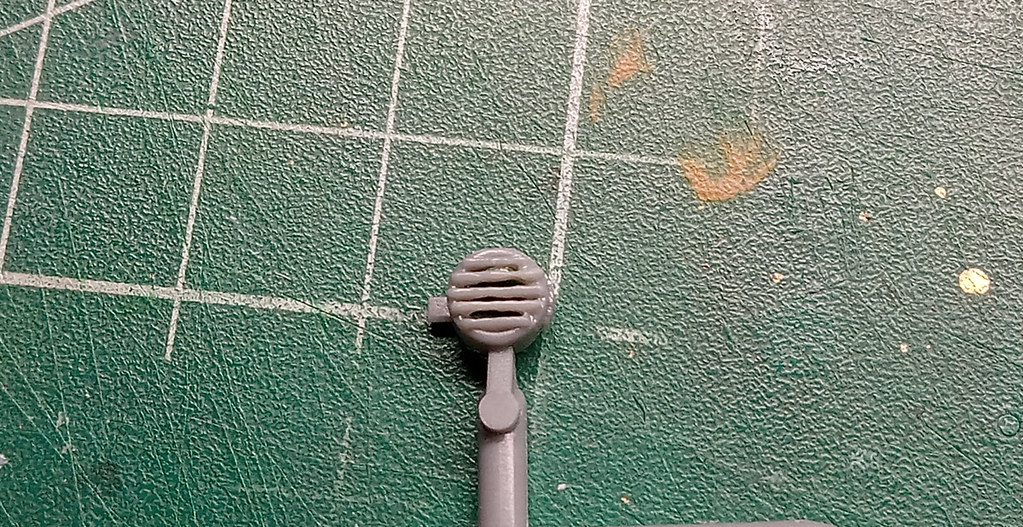

I made the piece from Evergreen tubing. The size used was near, if not, an exact match in diameter. It was a lucky strike. The louvers are Evergreen flat stock. For the lens I used a plastic rhinestone. I reduced its diameter to fit it. I left the facets as is and in keeping with the window facets. You won't see the lens much but it might produce an interesting visual when lighted.

And now I must sort out mounting the LED chip, and the wiring. It will probably require diverting from the original design. In my mind, that is not an issue for me. It will be close enough.