What does a day off and rainy weather = ?

Answer = Time at the bench.

I decided to take a break from lighting.

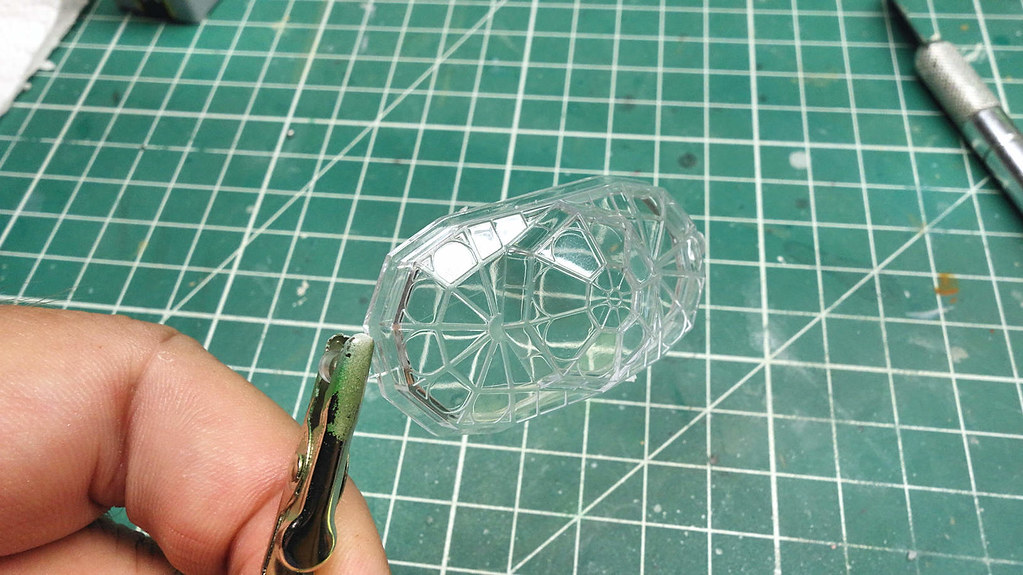

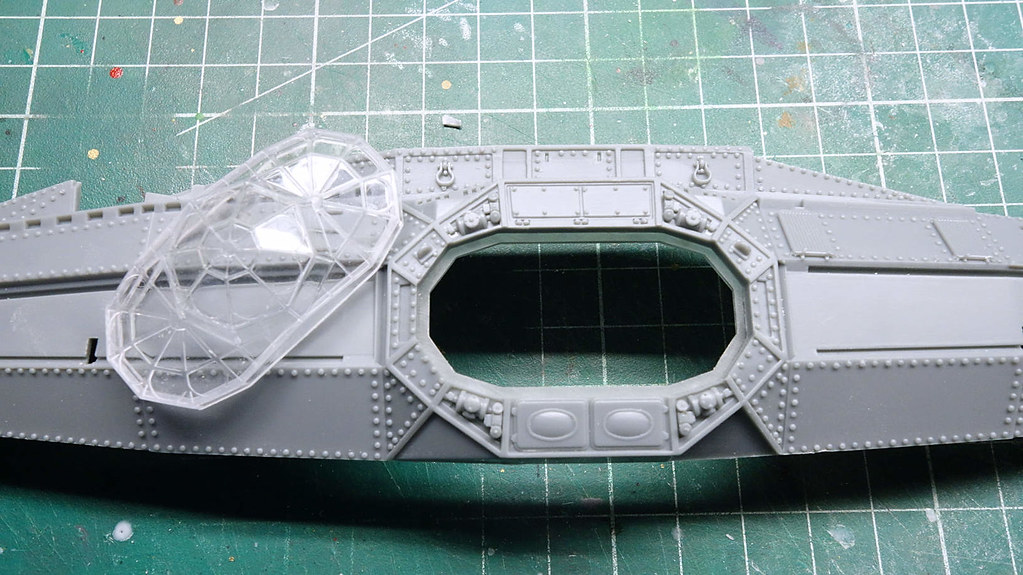

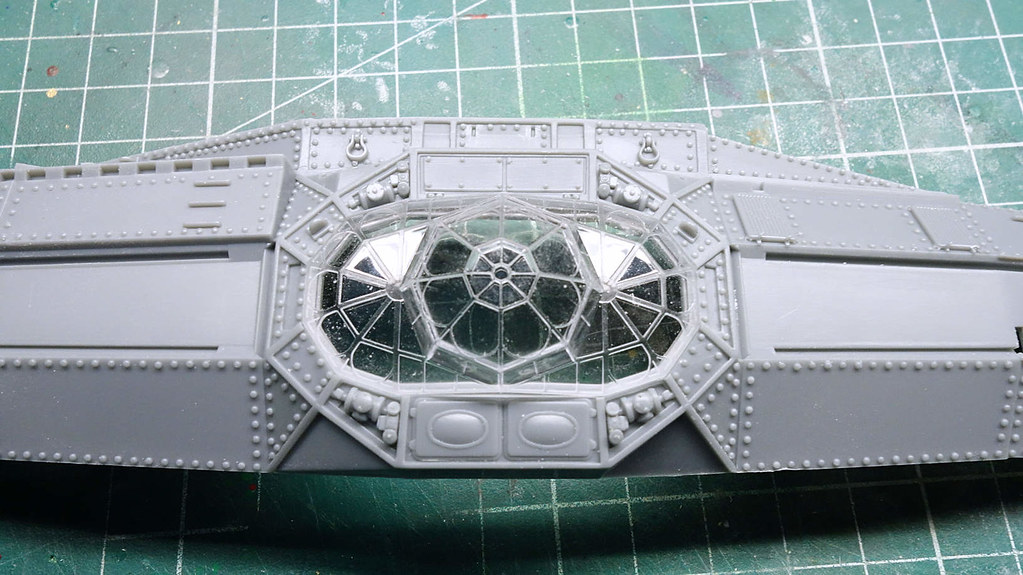

Below: As I have already mentioned I am making the windows removeable. The window assembly is designed to be mounted to the hull from the back side. That flange must go...

Using a razor saw and the flange as a guide to ride against I carefully cut through the plastic.

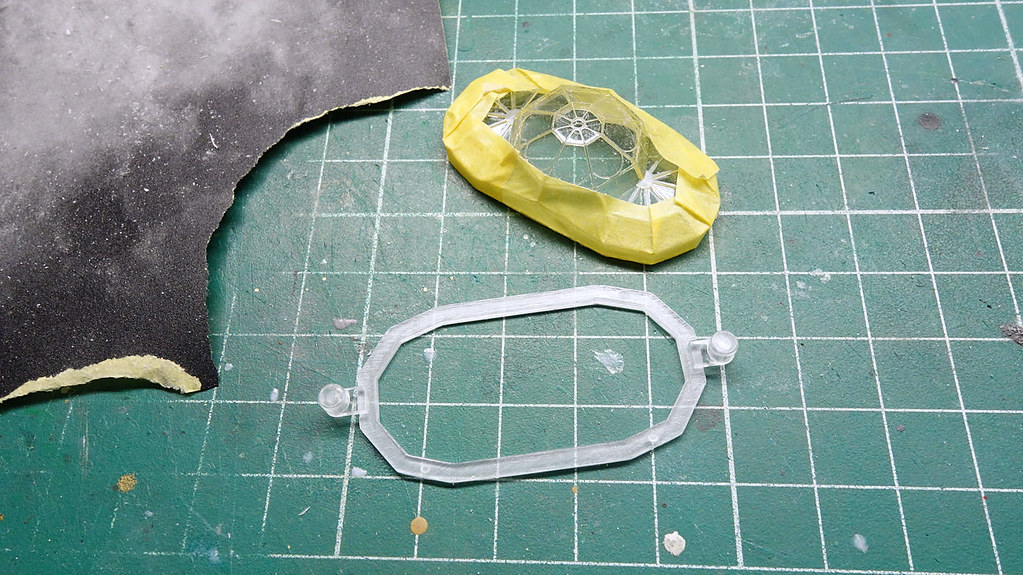

I am still using the flange only it is detached from the main window. The flange acts as a spacer and it maintains the integrity of the design.

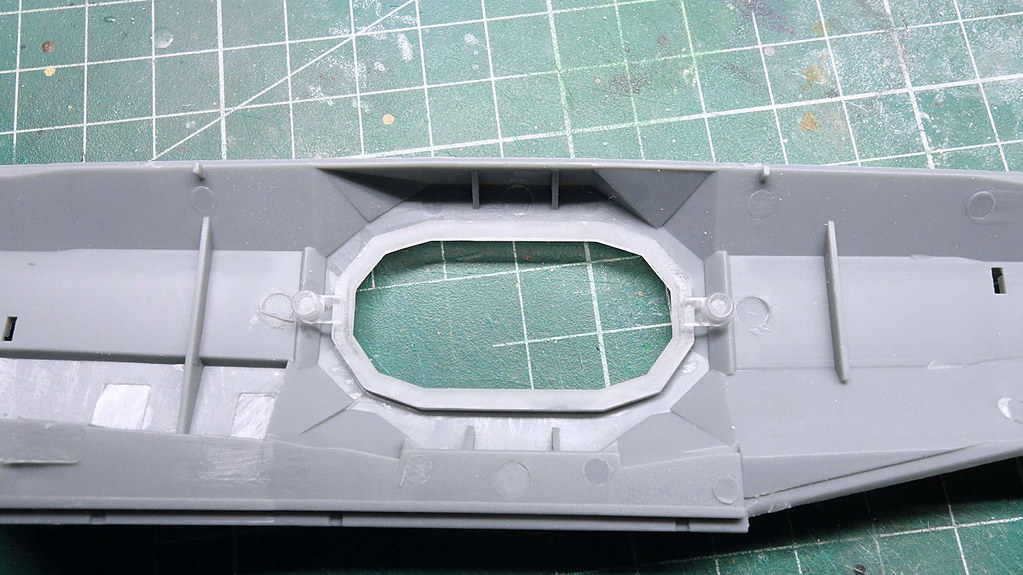

Below: The window fits into the recess perfectly. Basically, it is press fit. In its current state and without paint it slides in easily. I imagine it will tighten up when paint is applied. As is-- it's perfect. With paint--hopefully-- not too tight. If the latter-- some light sanding.

And as a sidenote: I know most of you know this and or have other ways to go about things but, for any new people-- this may be helpful.

I reach for this simple tool a lot. Basically, it is a sewing needle lopped off at the eye. It is used as an applicator for CA. What I love about it is you get consistent and small amounts of CA. I unscrew the bottle cap, tilt the bottle, and insert the needle into the CA. If by chance you get too much you can wick some off with a paper towel. In short-- you get small and precise amounts. I use this not only for applying parts but also for applying small amounts as filler.

Secondly, I found another use for the tool. It works great for applying small amounts of liquid mask.

Anyhow-- since I am off work today-- I think I will try seeing the new Top Gun movie.

It's good to be off from work.