Bakster

The good, the bad, and the ugly. Today, was the UGLY. I tried separating the mold and behold, it was stuck together... BADLY. I had to cut along the join to open it and the end result, the mold is trashed. It is a complete do-over. I DID use a mold release agent prior to pouring the second half but I suspect it's the wrong stuff. It is probably used more for releasing a resin cast than for separating a mold. So there you go, Dodgy. A learning moment for you at my expense!

And that is where I left off. This update will be convoluted because the process was just that--convoluted.

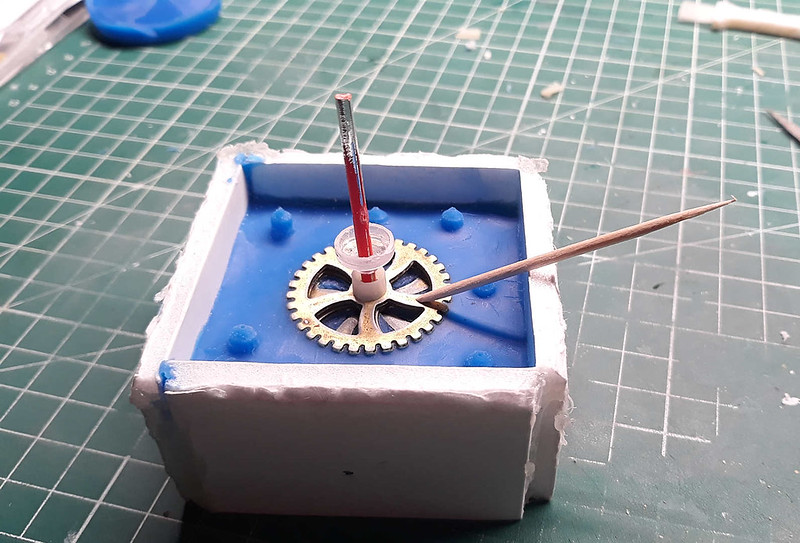

So, I made a new mold. This time, I did things a little different. I made the pour spout on the front of the wheel. I failed to image that before I poured the silicone so, the image below only gives a gist. You need to reconfigure it in your mind that the wheel would be flipped.

The toothpick is a vent for air to escape. I made the center pour spout by cutting the tip off a syringe. You will see why later.

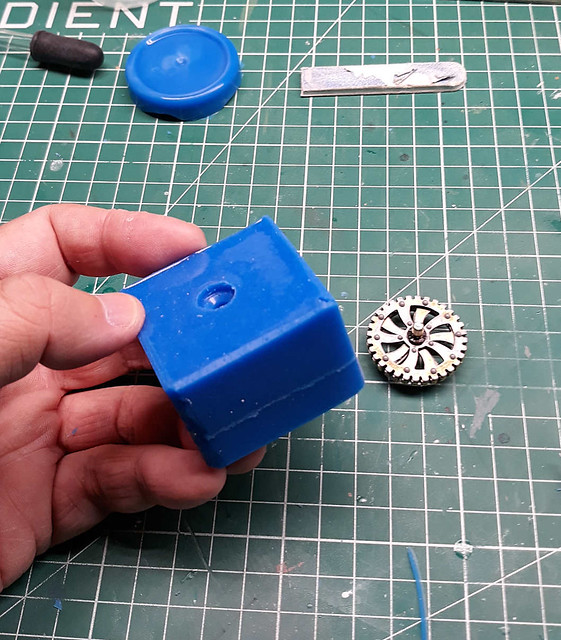

And... success. I applied a thin layer of vaseline before the second silicone pour. They came apart, no problem.

A nice little mold.

And now you see why I used a syringe to make the opening. Using the same type of syringe, it makes a perfect port to inject the resin. I opted to inject the resin because I had little faith pouring will work well.

And what was the result of the cast? The result was ... garbage. The piece had numerous holes, cavitys, and thin spots. Following this I tried another cast but this time I rotated the mold to try and flow the resin. The cast was much improved, but it still had too many defects. I tried other things, but the result was always the same, too many defects. The problem areas being the teeth of the wheel. The resin failed to flow into those small recesses, and this left gaps, and holes.

At some point I gave up on the idea of using the Smooth-On casting resin. I decided to try using Puduo epoxy resin. Puduo is too thick to inject, so the idea was to fill each half of the mold and then slap them together. It was an oozy mess, like an oversaturated PBJ sandwich. But in principle, it worked. I did get an improved piece. The problem? The problem like with most all casting resins--bubbles. I went through great pains to eliminate them, but they seem to appear later out of nowhere. This then causes divots. Once again exemplifying the need for a pressure pot.

Now what do I do? Since the Puduo worked, in principle--can I use the Smooth-On in the same way? I thought yes--but not the same way. Smooth-On is "Ultra" low viscosity and trying to PBJ the mold would not work well.

Ultimately, I poured the resin into the half that has most all the issues. I used a hobby brush to work the resin into the recesses and to help dislodge any bubbles. I then poured resin into the hub of the second half and then slapped the two halves together. I banded the mold and then injected more resin with the syringe.

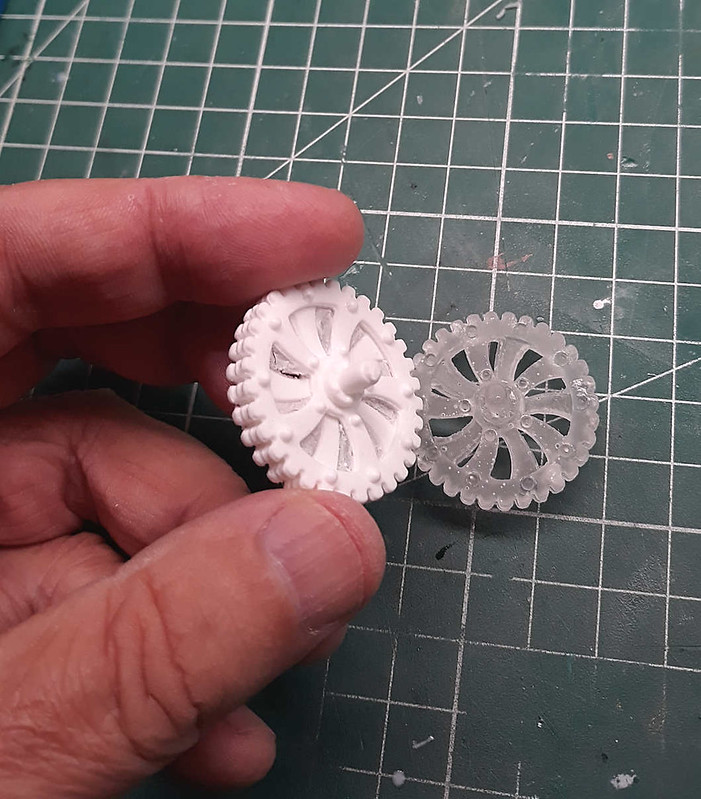

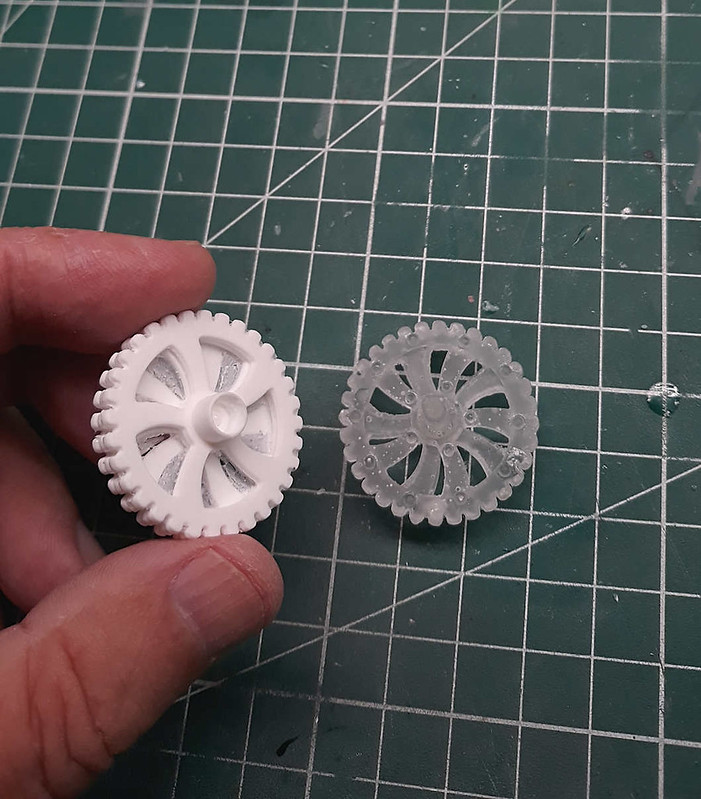

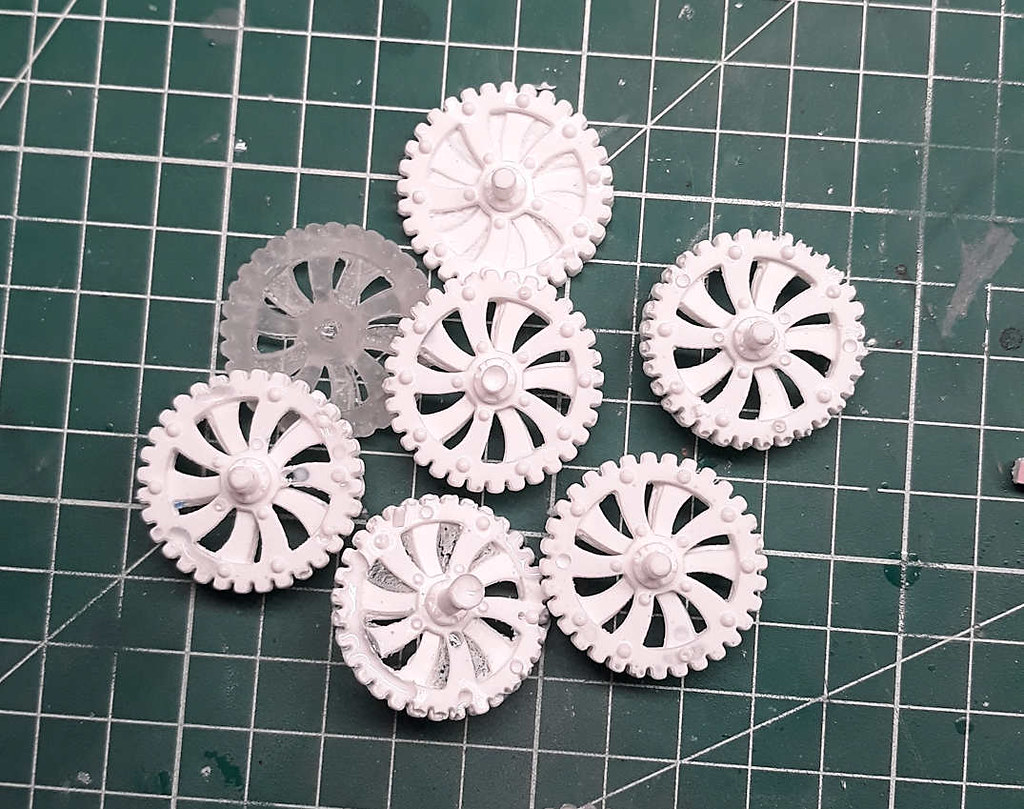

This then resulted into a good cast. There were still some defects here and there, but they should be fixable. And of course, there is more flash to remove, but not a big deal as they flake off easily.

I am holding the Smooth-On piece, the Puduo is below it.

Refuse pile. If you look closely, you can see some of the short-shots and such.

Some things to note:

1. Two-piece molds are not an easy thing, as I have learned. Particularly, when you have intricate detail. A better mold maker would surely have solved the problem differently, probably, through better venting. Maybe even by using a different acting resin.

2. Remember how I said I would use wax paper to hot glue the form to? Well, instead, I used aluminum foil and that worked well. The hot glue came off easily.

3. I really like the Smooth-On resin. It captures detail well, it sands well, and it is extremely lightweight. My model will not even feel the wheels. To that point-- the mission is accomplished.

4. The resin I purchased is a fast cure. It has a potting time of about 3 minutes. If I were to do this again-- I would purchase one of their slower cure resins. The one I have cures so fast you rush to get things done. This does not help me in my fight against air bubbles and air pockets.

5. The Smooth-On silicone rubber worked very well too. Btw. If you use their resin with their silicone you don't have to use a mold release agent when casting. It is recommended you do though, to lengthen the life of the mold.

6. Smooth-On has a number of helpful videos.

https://www.smooth-on.com/tutorials/

So where does this leave me? I need to cast another wheel. Here is the bad news that struck me one Saturday morning. If I want the spokes of the wheels oriented in the same direction for each side of the model--I will need to make another master that is oriented as such. Then I need to make another mold, and more casts. I guess the good news in this is that I should get my monies worth out of the resin and silicone, before they go bad. Always looking for the silver lining...

Egads man.