More progress has been made on the model.

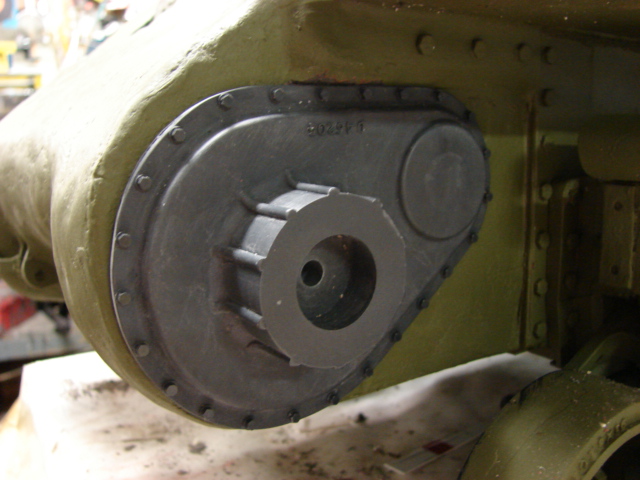

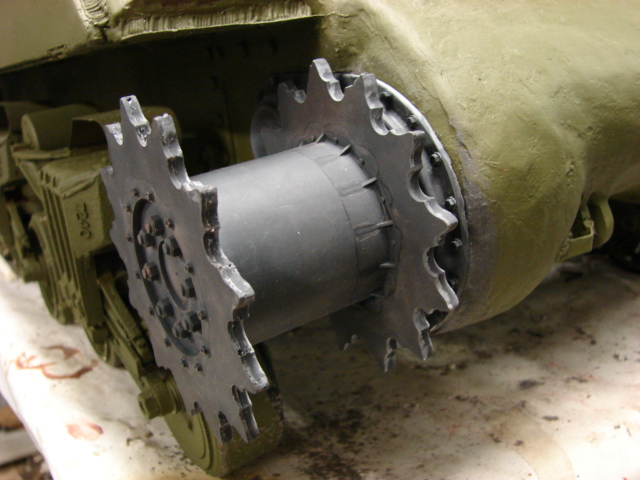

The panzerwerk final drives and sprockets were mounted to the model's hull. To mount the sprockets I simply drilled a 1/4 inch hole through the sprocket and mounted a 1/4 inch steel shaft to the sprocket. The sprocket is held to the tank securely and still spins freely.

the sprocket's installation went on with no hang-ups.

While I was finishing up the lower chassis I added some new parts to the product lines. http://www.eastcoastarmory.com/m4.htm

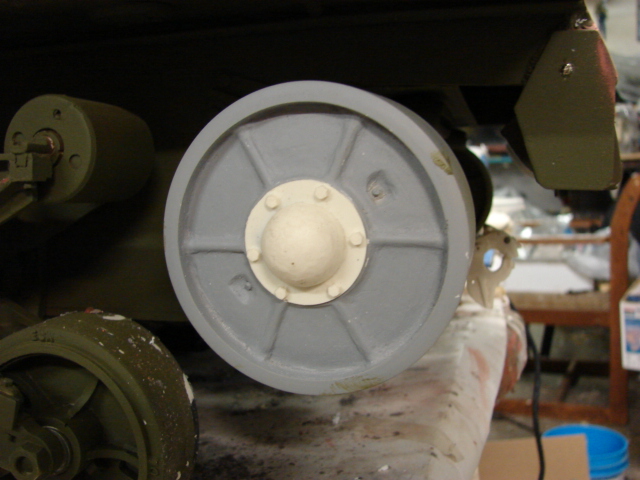

mid / late production stamped idler wheel set. Set includes two wheels and two hub caps.

Reversible welded over M4 spoke road wheel. On many shermans the open spoke road wheels had their spoke holes plated over to keep foreign objects to clog the wheel and to cause problems.

This road wheel is reversible with different styles of patches on each side. On one side you have ovular patches, and on the other side square patches. With this wheel you can have two wheel styles in one package, which can make mix and matching wheels easier.

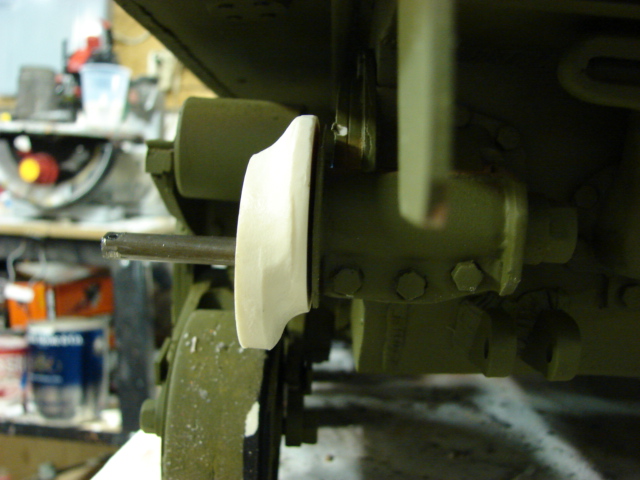

Revised Idler wheel mounts. On the tank's idler mounts I added the idler swing plate. with this new addition the idler wheels can now have their tension adjusted and the idlers will have a more realistic hang to them. Steel shafts are now included with the sets.

To mount the idlers to the shaft I used my retaining pin method. To do this I drilled a small hole into the shaft and use a washer and a coiled piece of wire. This system securely holds the idler in place and the mount but also allows the wheel to spin freely.

Once the idler is mounted the hub cap is added covering the mounting system.

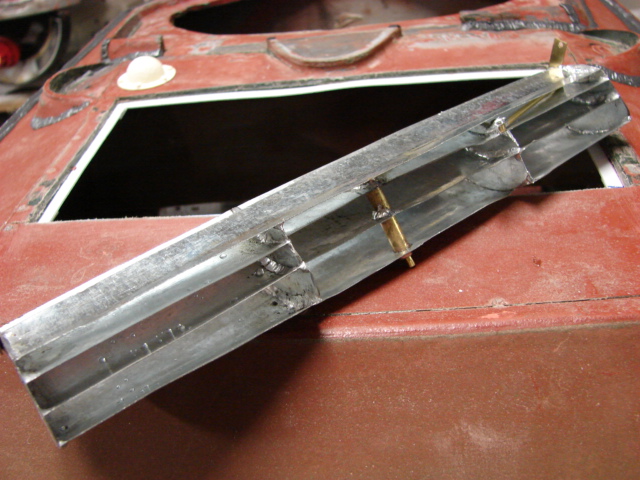

After the idler wheels were mounted I then fabricated the exhaust deflector flip grill. The grill is all fabricated out of sheet metal, and is fully retractable.

Almost all of the tank's upper hull weld lines were sculpted. On the upper portion of the hull two weld seams are visible. The first bead is for the original armor side plate. The second is for the jumbo's added armored side plate. Another note the side armor plate was actually comprised of two panels that were welded together towards the center of the tank.

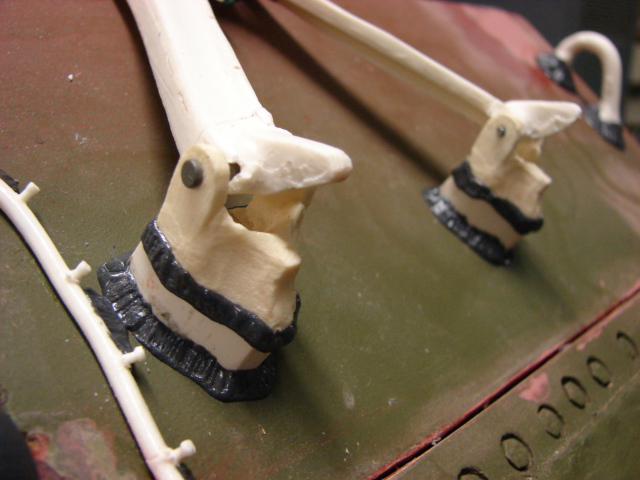

In addition to the weld beads the tank's tool posts and some of the rear upper hull details were added. These would include the engine hatch stops tail light, tail light brush guards, tow cable cleat, tow cable lock and the rear lift hooks.

The hull is now ready for the functional fuel cpas and the inner shelf was added to the engine hatch bay. The shelf is to hold the hatches when closed.

All of the tank's front hull detailing has been completed.

The front fenders were added and are scratch built out of sheet metal. On the Jumbo the fenders mount differently than they do on a standard sherman. Due to the thicker transmission cover the fenders have to mount to the tank's final drive bolts. This gives the fenders a sunken in appearance.

On the transmission cover the retracting comb wire cutting device and the tow cable mock was mounted

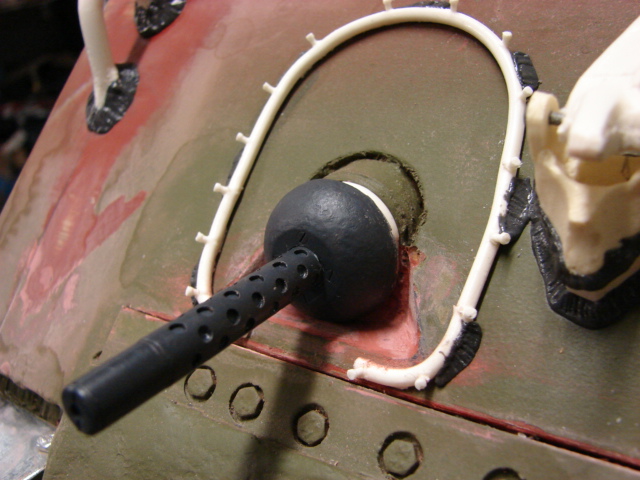

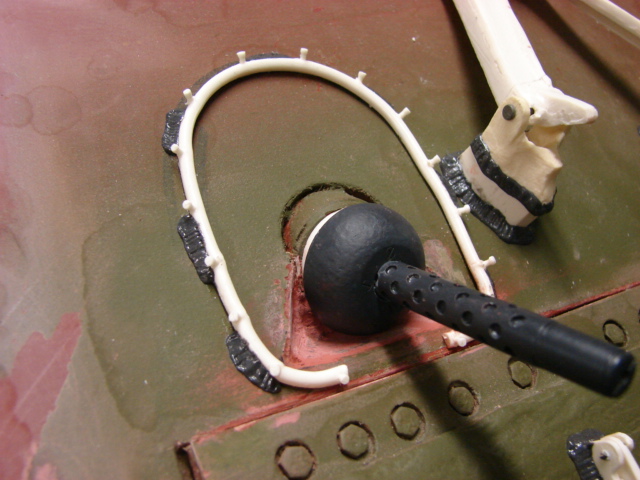

The front armored plate details differ slightly than that of a standard sherman. On the jumbo there aren’t any head lights, horn, or brush guards. Only the lift hooks, MG tarpaulin mount ring and the 75mm travel lock. For the bow M1919A4 I used the panzerwerk bow MG set.

On the Jumbo's 75mm travel lock the two mounting lugs were elevated off the front hull via two risers. Scrap chunks of resin were used to make the risers on the travel lock and the retaining latch.

I will now be focusing on the tank's folding rear rack and rear detailing. I should have the hull fully completed by the end of the week and will then be starting on the turret. The whole tank should be ready to paint in about two weeks. More to follow.