Over the Winter I had an idea for a 1/6th scale post WWII / Nam era vehicle project. The Vehicle was to be an M151A2C Mutt w.the 106mm M40 recoilless rifle.

Before I would be able to dig into / commit to this project I decided to develop the most important aspect of the project first... which would be the M40, as if I were to hit something unfeasible / impractical to execute with my tooling the project could be axed before the project proceeded to far and funds would be lost.

For this project I wanted to venture out of my normal medias (resin, metal... etc) and develop the M40 (and eventually the Mutt parts) utilizing as many 3D printed parts as possible as they have several advantages to them compared to other legacy medias.

After a few months of late night tinkering with several types of software I was able to complete the gun, and in a way where I can release it as a full kit.

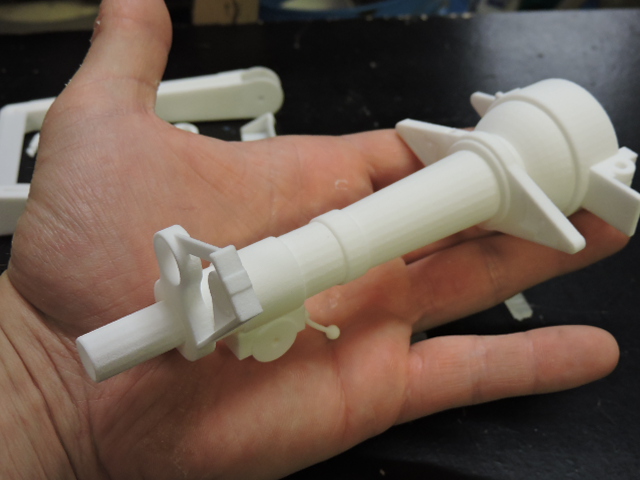

Like I wrote above the main contents of the model are all 3D printed parts. The only part that is not printed (outside of some assorted metal bits) are the barrel sections and a cast rubber eye cup for the optic.

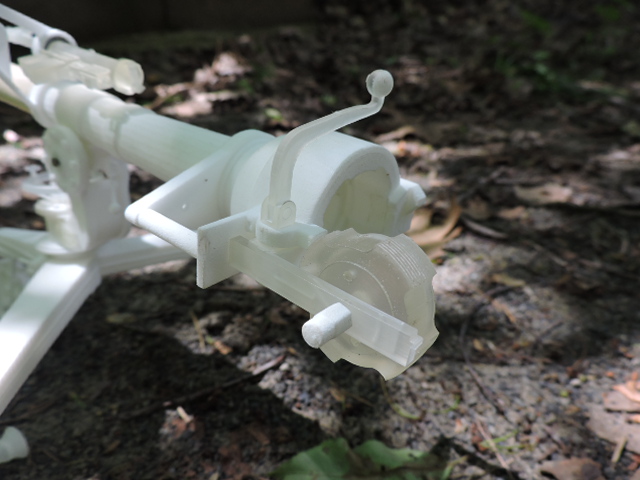

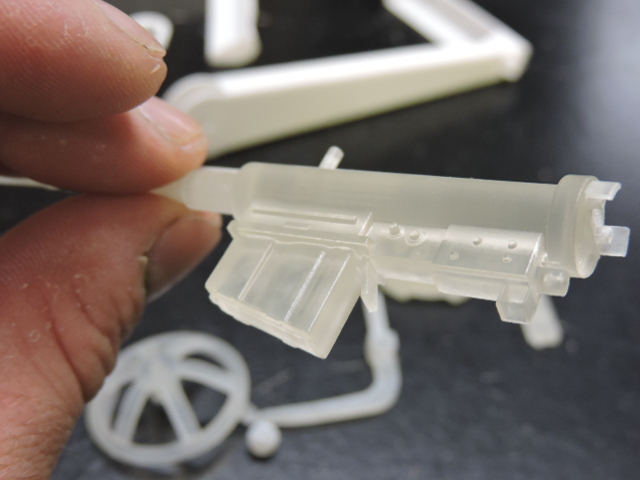

one of the detail features that I wanted to build into the model was the ability to have a breech block that could pivot / lock so that the model can be displayed in either a loaded or unloaded state.

Another plus that I learned about this type of media is that unlike Resin I can have many detail parts that would normally need to be separate parts that get glued / mounted on in sub assemblies... with this media they can all be integrally mounted which cuts down on parts required / build time. This can be seen most notably on the tripod legs and the main rear receiver section

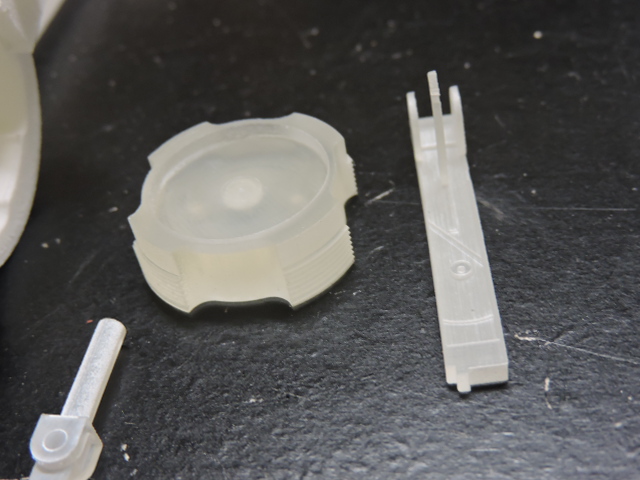

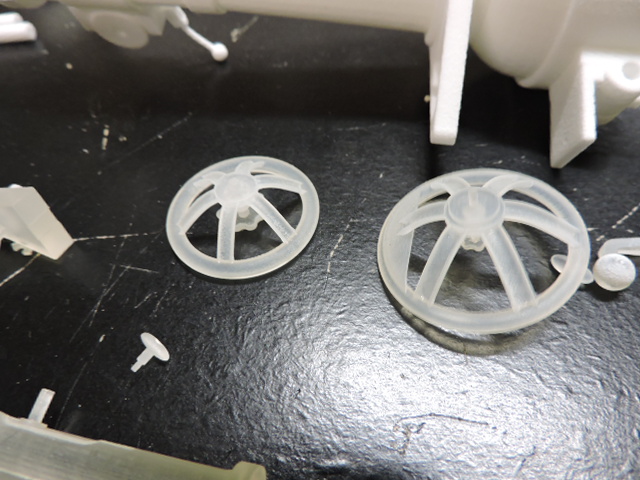

For smaller parts where fine details are more present I opted to use a different printing media, which if I were to fabricate these the old way would be much more difficult to not only fabricate but to mold / cast.

This is most notably seen on parts like the Crank wheels, optic, and breech block parts. However where this material really shines is on the Data plate where with this technology I was able to get all the mfg info to be present.

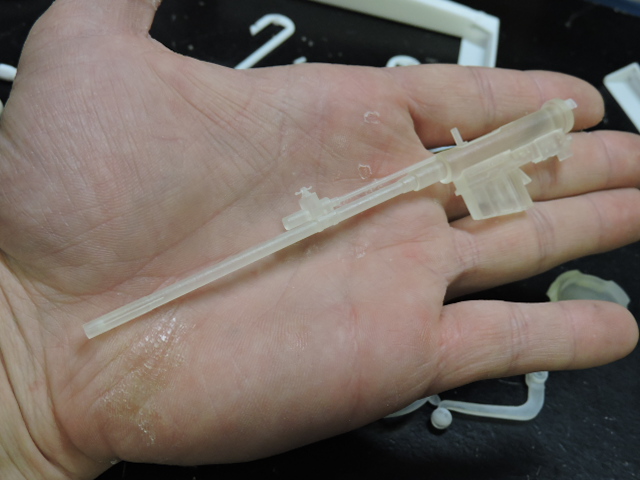

As well as the M8C spotting rifle. Which was a particular enjoyable piece to design

For the optic, I went with the HD material for both detail retention, but also because of it's translucent nature makes a great platform for the lenses as they don't need to be painted. As for the eye cup, like I mentioned above this is a cast rubber part. No paintwork is needed and gets mounted in it's raw material.

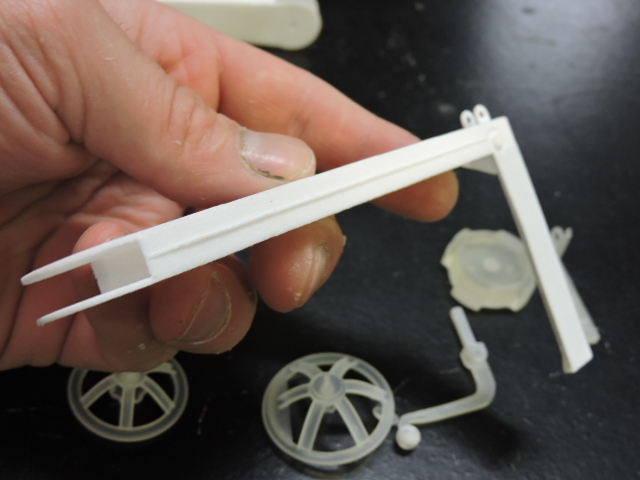

For the model's M79 tripod, I designed the rear legs to be adjustable, and the vehicle clips to be functional as well.

The vehicle clips are also functional. As for the front the front tire spins.

Once all the parts were in hand the first gun model went up very quickly, After my experience with building the first one I saw room for improvement. These tweeks were made and the second gun was built.

The gun is on;y really half of the equation. Once the gun was done I tooled up some ammo. Currently I have the HEAT round and a spent casing. Because of the perforated cases on these weapons the 3D print media is probably the best and only real way to replicate this feature.

For the loaded rounds because the projectile and the case are separate parts this allows me to insert a paper liner in the interior of the shell which is very close to the combustible propellant material that would line these shells in real life.

Even though this project started out as a side "why not" exercise in looking into new fabrication techniques... it kind of grew into a whole range of variable and options... as once I had the basic configuration I then ran with the project creating a few different variations in the process... which I'll be posting shortly, but until then here is a sneak peek :p.

The kit has been posted on a new section of my website that will focus on heavy weapon sets, http://eastcoastarmory.com/heavy_weapons.htm

Which after my experience with the M40... I defiantly see some 1/6th scale Artillery being developed in my future ! ;)

In addition to the above I also made two youtube videos that go into more detail on the kits features.

https://youtu.be/NRJgUz74m0M

https://youtu.be/jDsQhykY7T0