I've been making slow progress with building a MiniArt Valentine, and after completing the rest of the build, I couldn't put off assembling the tracks any longer.

I'd watched a VMS video on Youtube which seemed to show a good way of going about the track assembly.

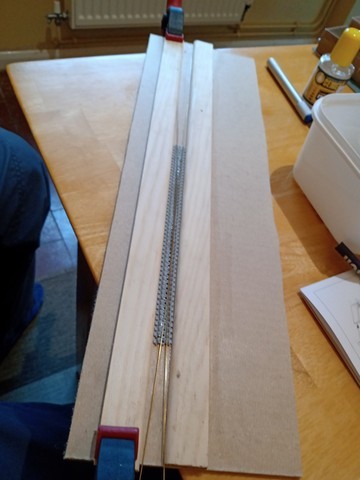

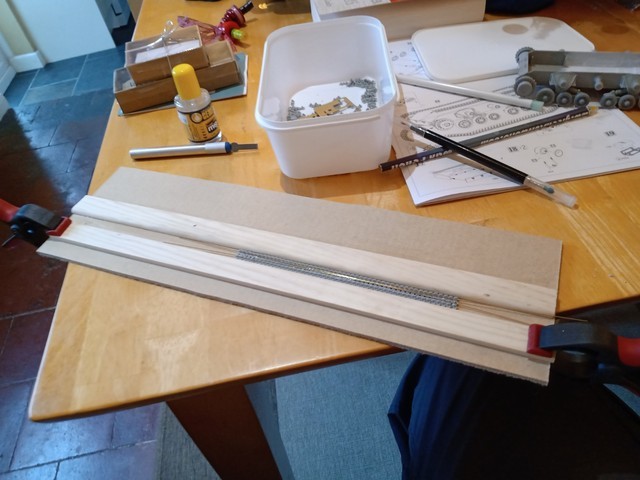

Yesterday I bought a piece of mdf sheet and a moulding strip. The strip had one square edge and one rounded. I cut off a piece of the sheet and glued a section of the moulding down the centre. I did it down the centre so that I could use either side (square or rounded) as a guide. I cut a second piece that I'd also use as a guide, but clamped rather than glued so that it could be set to a size to match the track size, and so that it could be removed easily.

I then started placing individual links into the guide. I wanted to make the track in two parts so that it could be easily removed from the tank for painting.

The first ten links went in fine but as more links were added, the earlier ones started to ruck up. Initially I used some brass wire to try and weigh down the links and keep them in place. However, I then realised that a third piece of moulding on it's side would nicely sit in the gap between the track prongs, and would make an excellent tool to keep the tracks down and in place.

Once the links were in place, it was time to glue them. I'd hoped to use the VMS slow setting styrene cement, but it's been on order for ages - so instead I tried a couple of alternatives. I realised that the humbrol cement I already had took an hour to set fully so was a possible candidate. However, I also bought some Ammo of Mig Slow Dry Cement which I hoped would work.

For the first section I used the Ammo of Mig cement. I attempted to touch a spot of cement onto the joint between each link, but this proved quite difficult, and in the end I just painted the cement onto the links. I let them dry for a minute or two - until they were stuck together enough to stay together.

Being able to remove one of the guides, and use the moulding edge to move the track as one, helped a lot in moving the track so that it didn't stick to the guide, and lift it as one piece. Also I found the rounded edge of the moulding worked fine for the main jig and I didn't need to try using the square edges for this task.

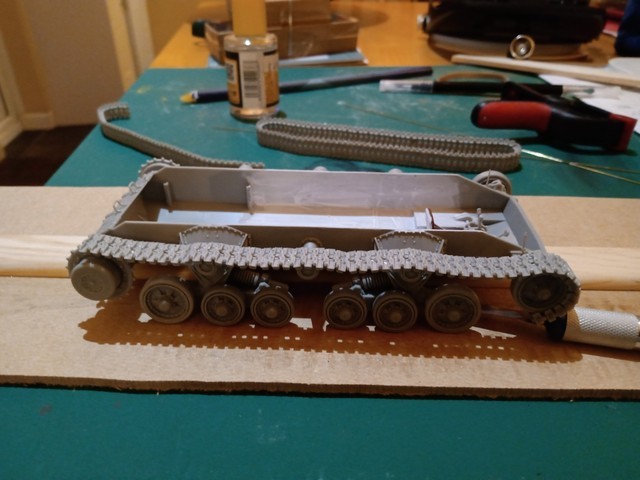

I then lay the track onto the wheels - starting at the cogged sprocket - about halfway round to give a good guide point for joining the two main sections of track. I lay the first section along the bottom of the wheels. Once it was moulded into place, I removed the track to make sure it wasn't stuck to the wheels. I then placed it back in place to check the shape. I did that a couple of times. Once the track was holding it's shape, I found I could place it one its side and it would keep it's shape. So I left the track like that to set.

I then started assembling the next section of track. This time I used the Humbrol cement, and this worked better because this cement was thinner. It was easier to applied smaller amounts into the joints between links. That is, with the sections abutted together, I touched a drop cement onto the joint and let it run in between the two links. I used the Humbrol cement for the rest of the sections. I then repeated the shaping of the tracks to the other side of the Valentine hull.

Once the first section of track was dry, I started assembling the next section of track. This section I lay along the top of the wheels. I put the lower section in place so that I had the right starting point on the sprocket wheel. Once I had the section in place I started to shape it with my fingers to get a bit of sag between idlers.

Again I lay the track on its side to dry once it started retaining it's shape. Once it had dried, I placed both upper and lower half sections of track onto the hull. I found that I had to add a couple more links to get them to join, but this was fairly easy now that the track had retained it's shape.

With that done, I had one completed track.

It was then just a case of doing the same for the last section of track.

All in all, it wasn't as bad as I feared it would be. I'm glad I did the prep - to build the jig and get a couple of cements to try. As a first attempt at assembling this kind of track, I'm pleased with the result.

Unfortunately, I think it will be next weekend before I get some time to start painting, but I think this has been a successful afternoon's construction.