This is the T-50 light tank. There is lots on the web about it so I will not waffle too much about it. Here is the one at Kubinka.

I will try and build this in 1:16 scale from scratch, the building materials will be steel primarily.

I built a Maresal some time ago and the angles drove me daft so I want to try and do another angled tank but try some new methods of getting the angles correct.

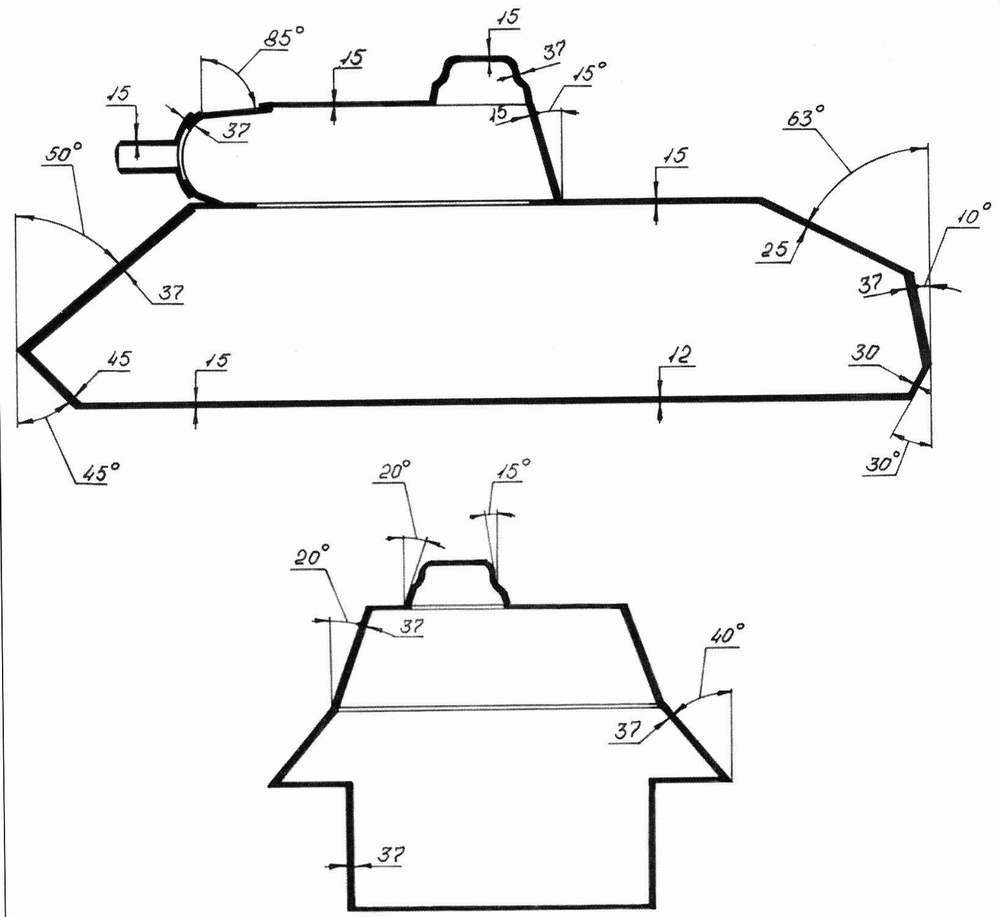

The relevant angles are in this picture:

I bough these cheap from China to facilitate the angle placements - they are thick enough to work as supports and I have two sets which makes things easier.

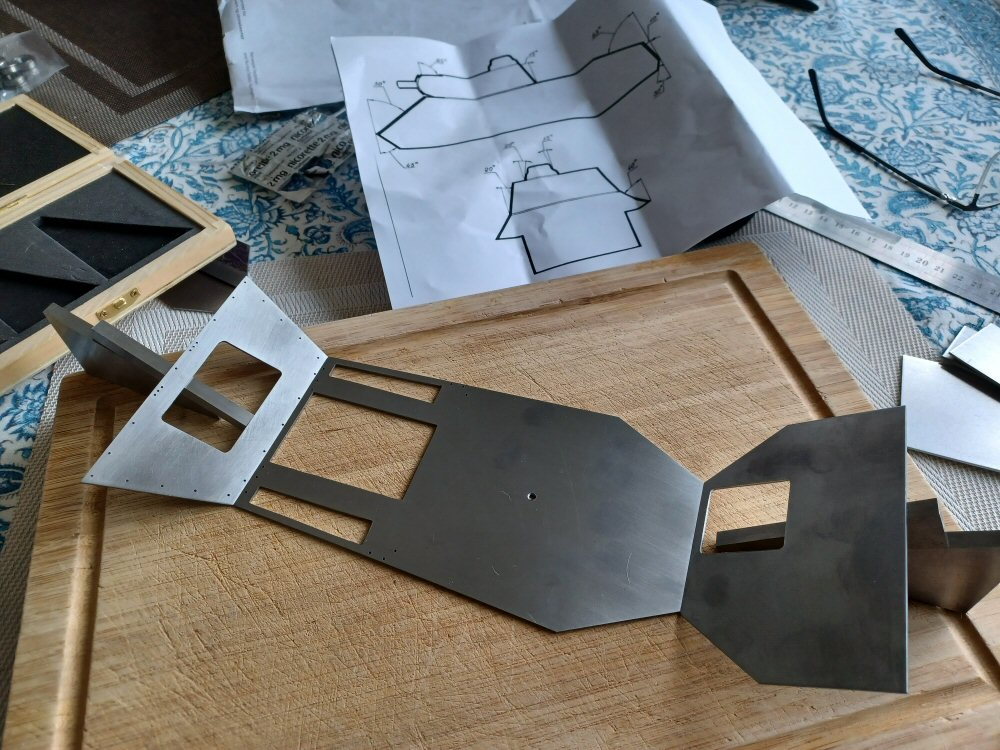

I will use them like this to hold the plates for soldering:

All structural bits are made from 1.2mm mild steel plate that I cut with a hacksaw and filed to shape.

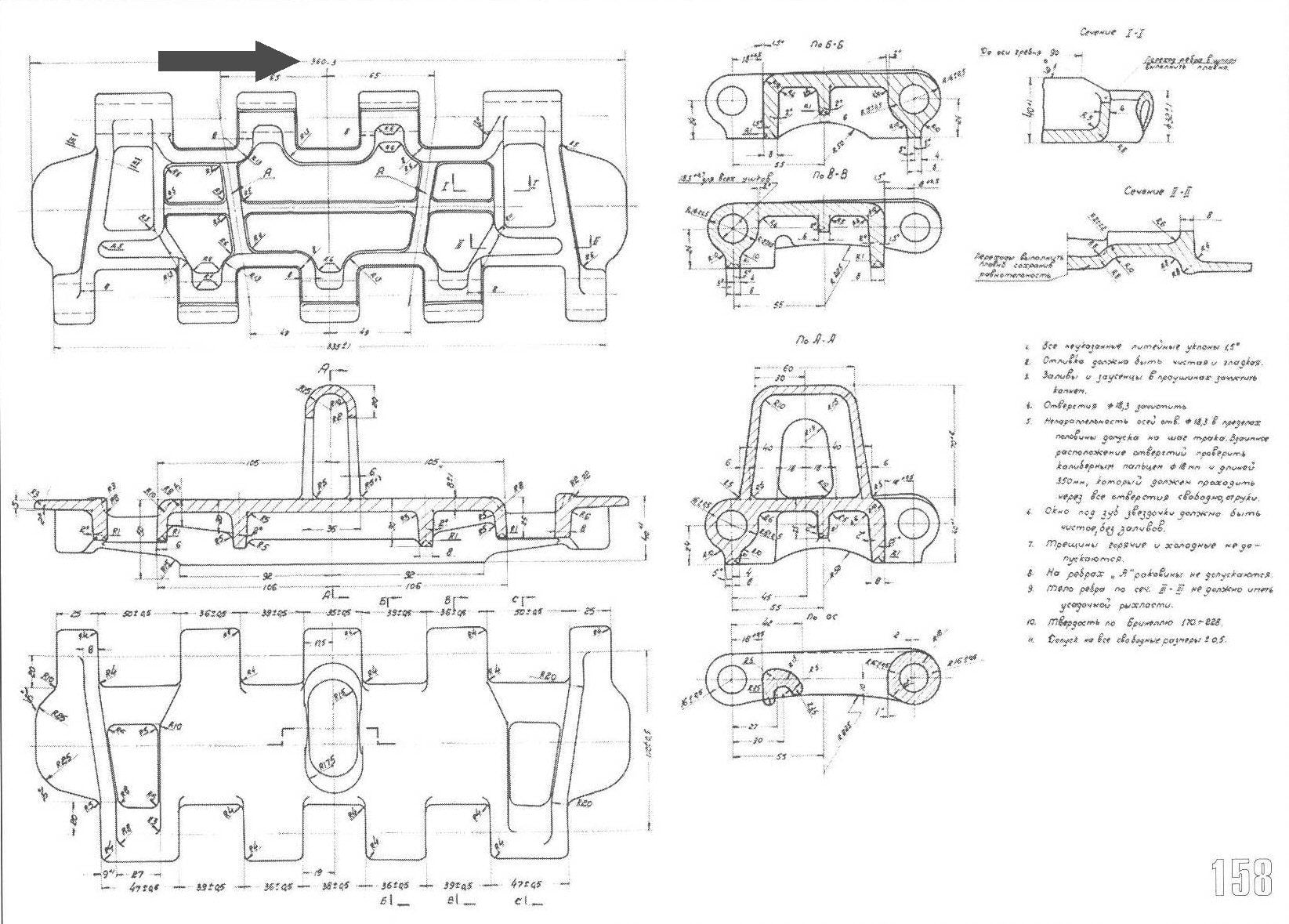

For tracks I am using Stug tracks as according to this:

the widths are about the same and it has the central tooth format which the T-50 had.

I started with the road wheels. Here are the blanks from stock steel bar.

Then I abused my tiny proxxon drill for an hour to get all the holes made.

and ultimately ended up with these:

A major problem is this turret:

which is not symmetrical about any axis but I will get back to that later.

P