Here is a project I built two years ago. I spent about 400 hours total constructing it. A gantry is a pedestal used in large construction projects to give a crane added height and reach. I've divided the post into two parts: fabrication and then finishing. Here is the fabrication part:

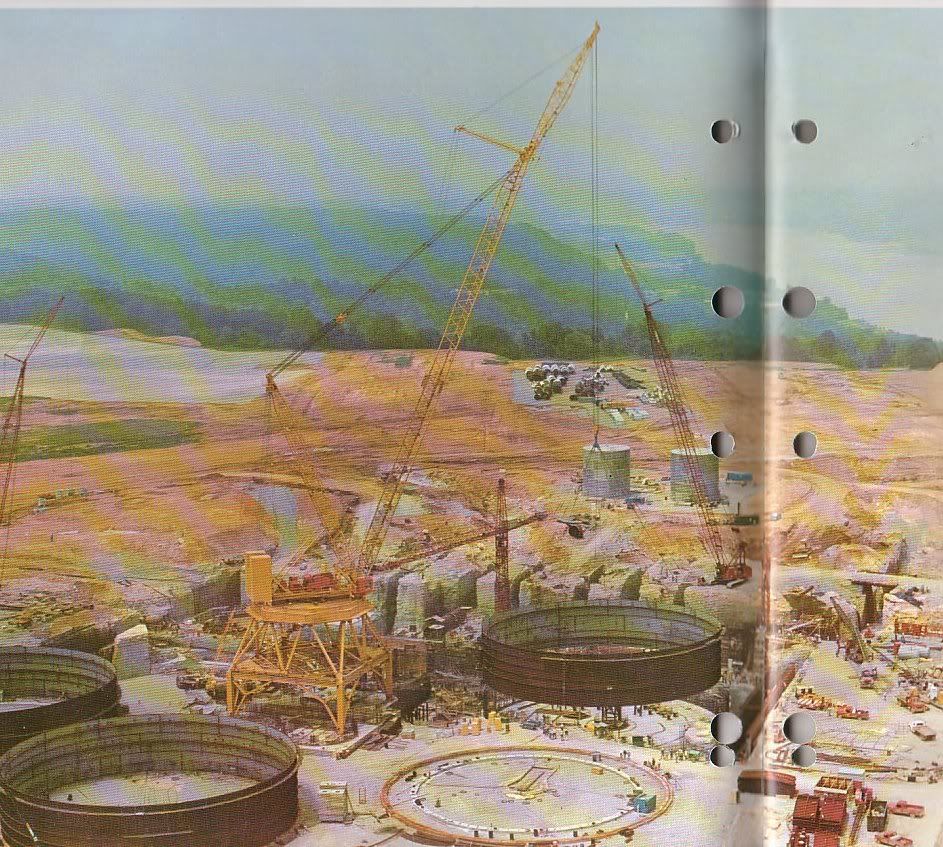

Here is a photo of the gantry that I based the model on

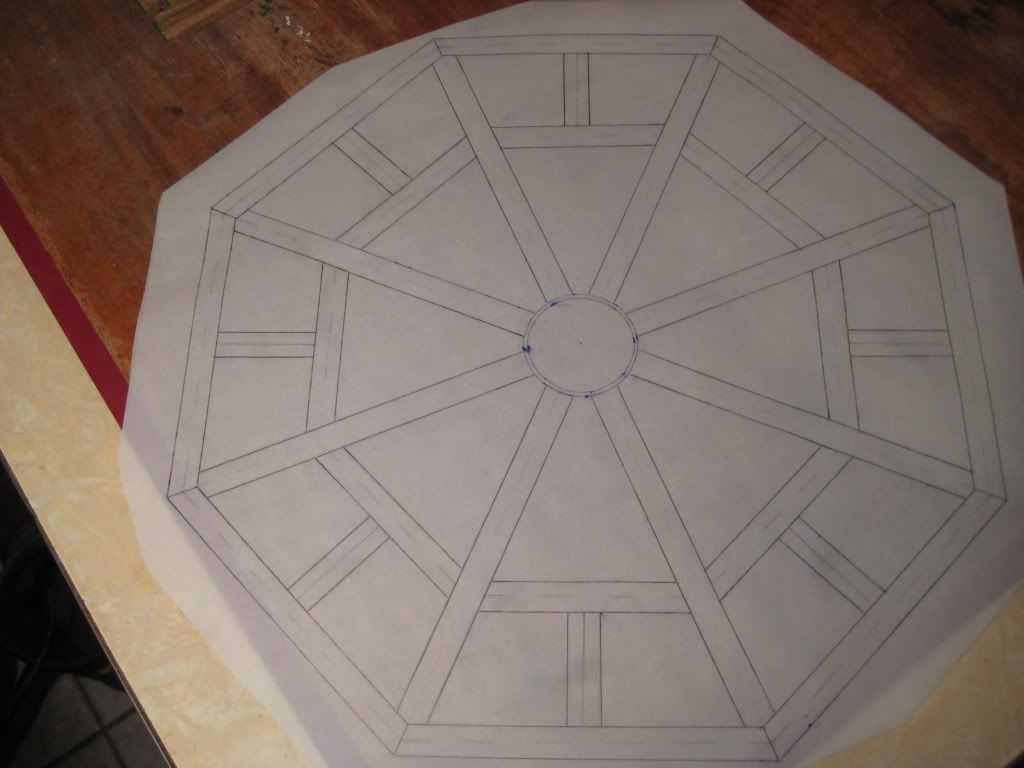

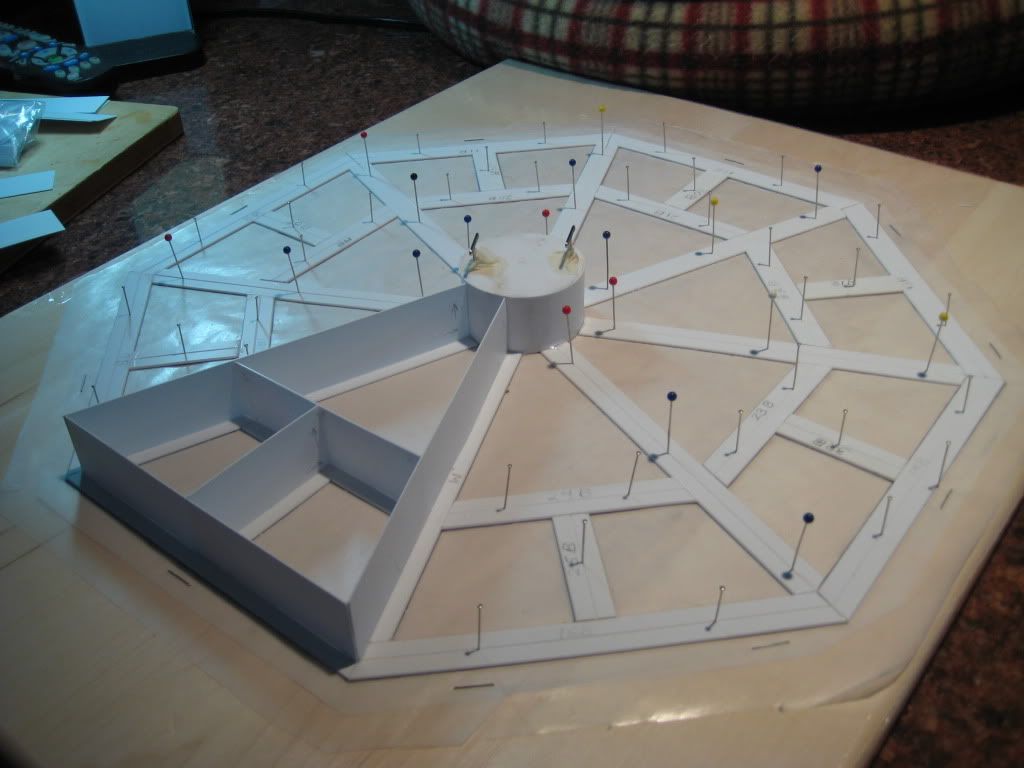

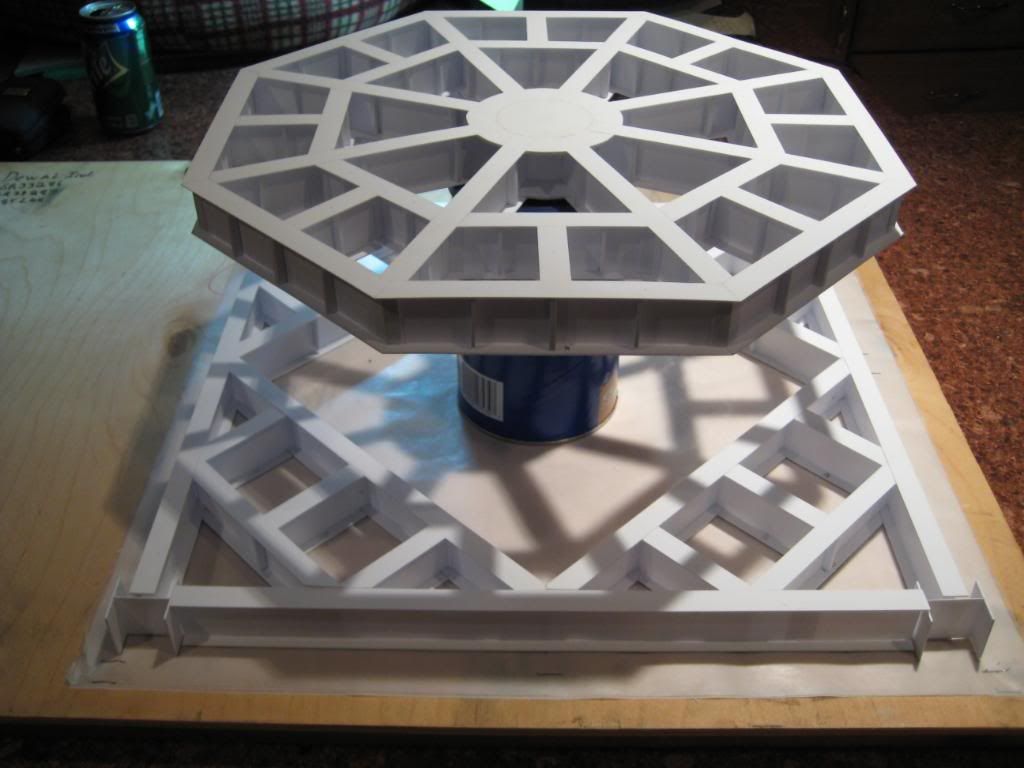

Here is the drawing I made for the upper deck and, the deck fabrication

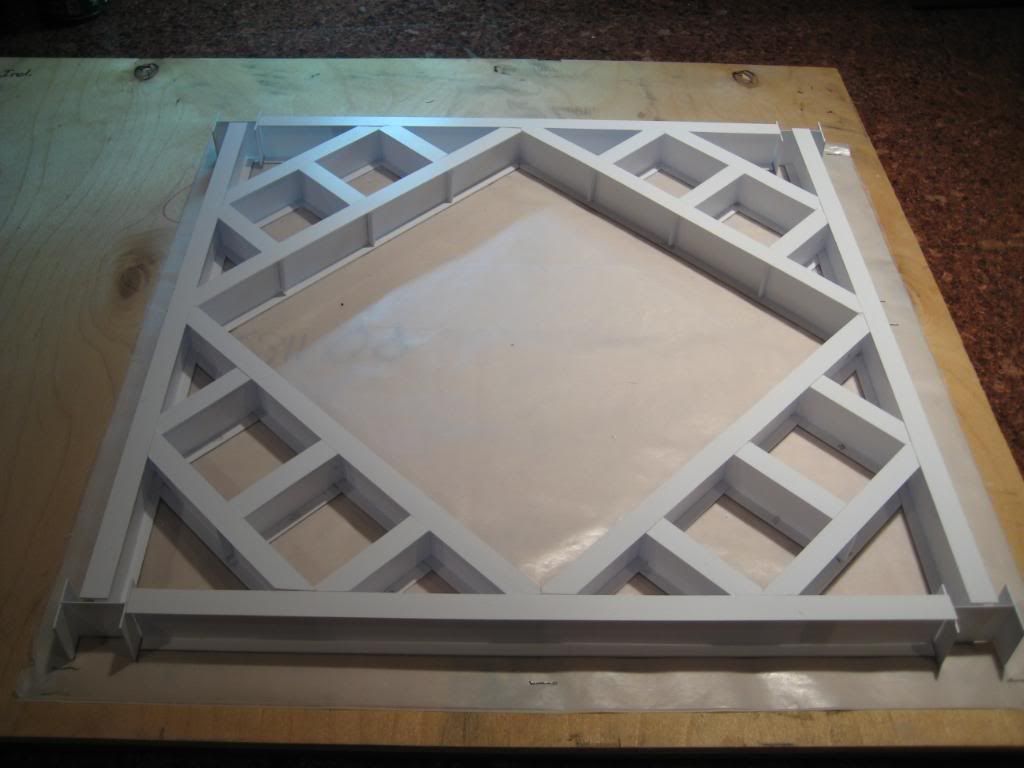

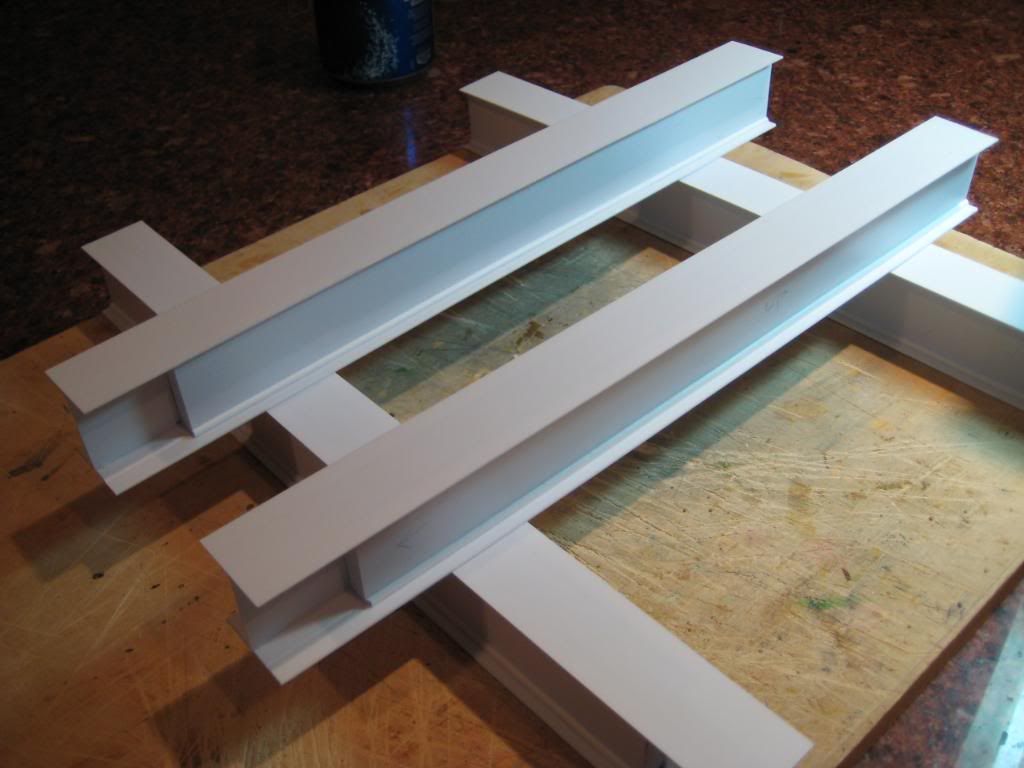

Then I made the lower deck the same way

I then carefully aligned the two decks on the assembly board.

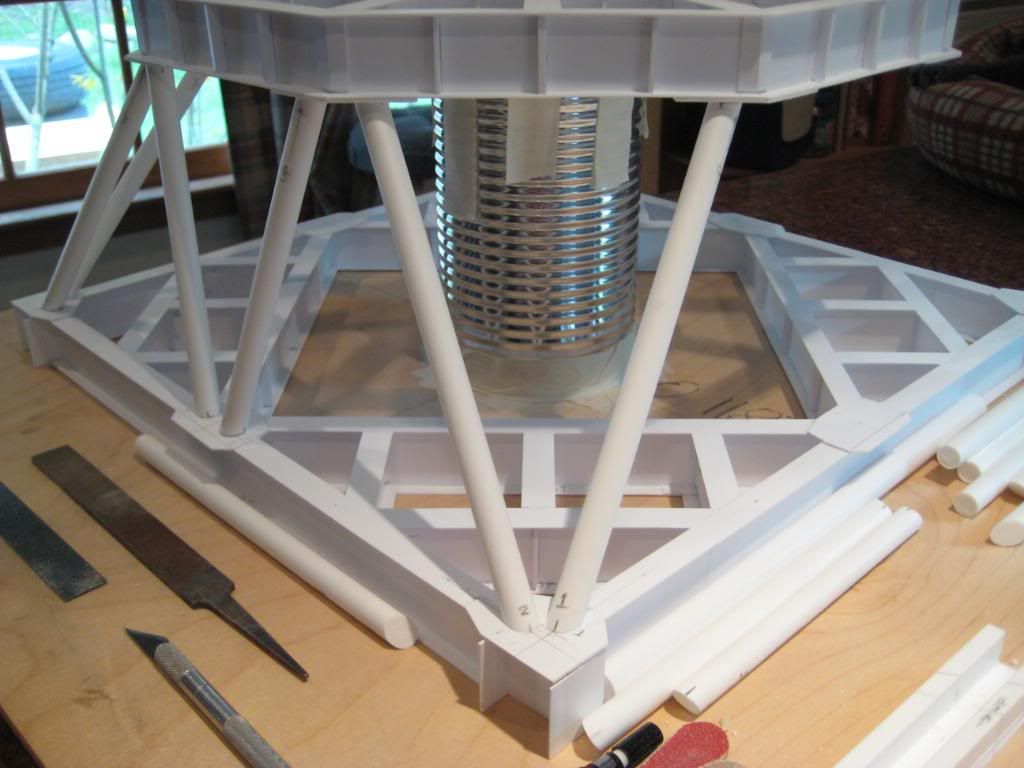

Next came the most technical part of the build which was to make the compound angle struts that hold up the upper deck. I made two master jigs for the legs. One set of legs was slightly longer and had a less of an acute angle while the other leg set was shorter with a steeper angle.

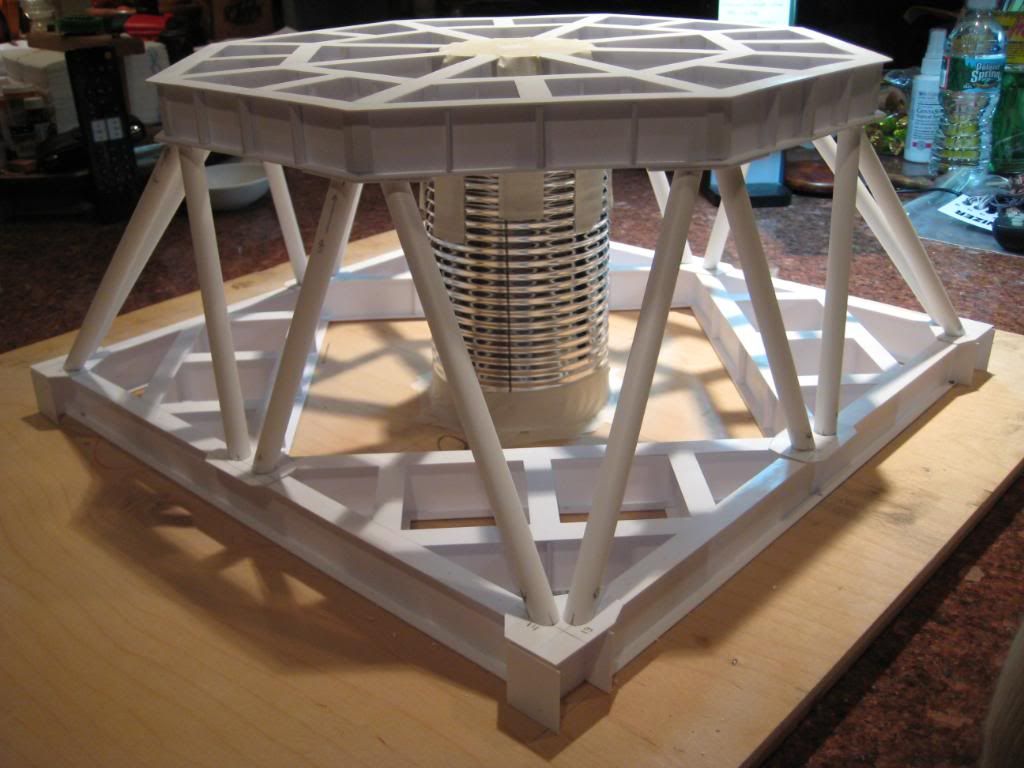

After the glue was thoroughly set I tested the deck with a 12 pound static load. The model crane going on top weighed 10 pounds.

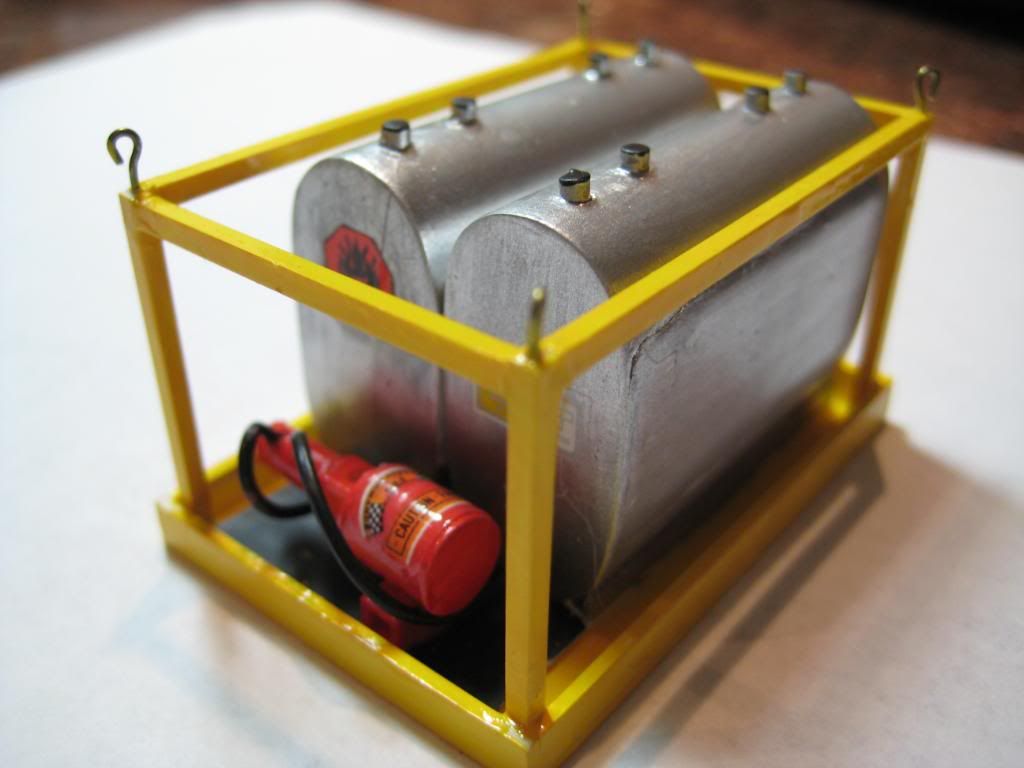

Meanwhile, I started building small accessories that would go on the gantry. Here is a portable fuel tank for the crane

I built a portable light trailer for electrical generating power.

I then made the lower legs. The legs are made up of 27 parts each. They are very strong.

After the legs were attached, I started on the upper catwalks.

The crew is seen here assembling gear for the air and electrical systems

Then came two sets of staircases

Here are the completed staircases, walkways,support struts and portable braces

This I-beam slips out so the lower stair can be safely transported

Here is the completed gantry before paint with a Manitowoc RINGER crane placed on top. The upper deck decking will be applied after the model is painted.

The next post will cover air brushing the model.