Hi John. Sorry for not responding before now. Interesting indeed. So far it has been fun figuring out hot to make things work... so far! I am used to finely molded parts in the hundreds. Not crudely cast parts in the tens. Low tens even. The wind details definitely looks like they were going for fabric. I am not putting this kit high on the accuracy scale.

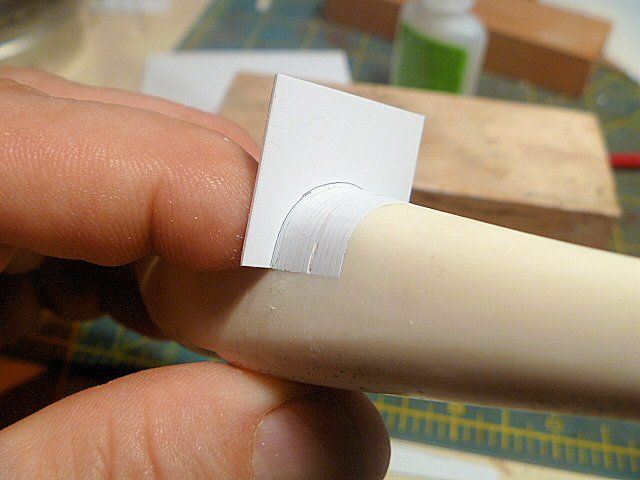

Back in the day when I built RC stuff I remember that if you needed to cut a bunch of pieces the same length,, you had to use the 1st one cut all the time to mark the length. If you used the last 1 cut each time the pieces would get longer a little each time. I used that to my advantage here. I glued layers of .30 plastic and traced the outside each time and cut a new one. They did in fact get a bit bigger and only needed a little sanding to be a smooth progression.

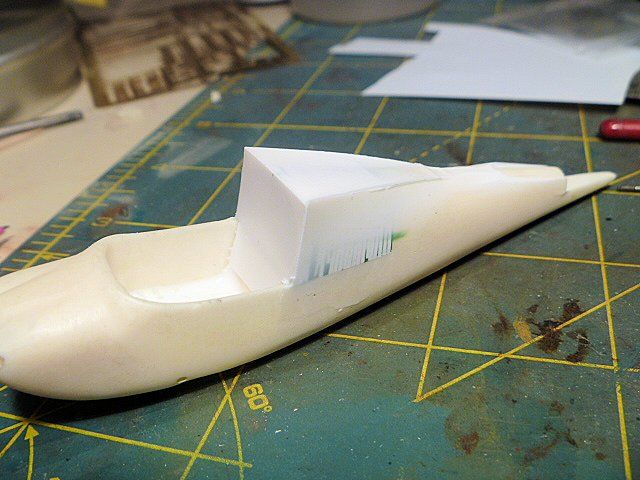

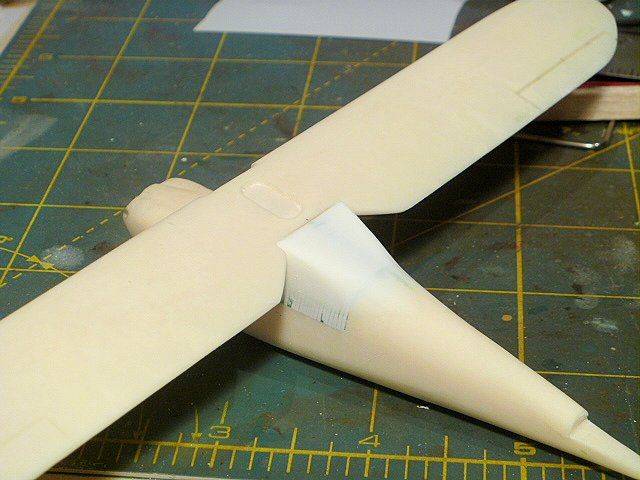

I sat there thinking I was real clever until I tried the wing. Left out a few of the words that make my wife say, "And you find this relaxing?" The fuselage needed to widen and flatten to join up with the back of the wing. Some thing plastic was taped to the fuselage and the cavity filled with resin.

Some filing and sanding and it blends nicely. The reference lines drawn off the LE notch show the notch is too far left. That, and the oval window, will be filled and moved.

And what a PITA air bubbles are. Fill 'em, sand 'em, expose more that were under the surface then fill 'em, sand 'em, expose more that were under the surface. You see where this is going. This 1/48 kit will be 1/144 by the time I fill all the air bubbles.