Now it is on to the deck details - starting with the capstans. The one provided in the kit sucks and begs for replacement. I also need to provide one for the gun deck.

But how to do the drumheads - especially when using styrene? I pondered and pondered and finally came up with an approach that worked reasonably well. The key was to visit the local hardware store to acquire some metal washers of appropriate size - 1/8" (#6) did the trick. The washers will serve as the outline of the circles as we spin everything around on the drill press and use a file to shape the drumhead.

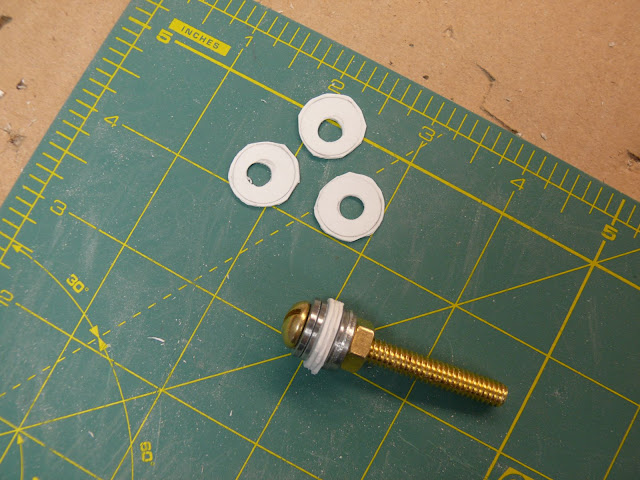

Here are the raw materials:

After outlining the circles on some sheet styrene (using the washers as a template), I punched the centers and rough cut the shapes. Those were then mounted on a bolt sized to the washer opening with two washers sandwiching each side of the styrene. Everything was then clamped tight with the nut:

I mounted the set up in the drill press, gave it a whirl, and filed the edges even with the washer templates:

After removing the styrene from the bolt - viola!

Next I snipped some small styrene stock (.040 x .080 Evergreen 144) and glued them around the perimeter leaving spaces in between to represent the bar openings:

After sandwiching those between two of the styrene "washers" I nipped off any protruding material, mounted the rough drumhead back in my bolt assembly and gave it another spin with some light filing to clean the final shape.

The whelps were easily managed - just stuck some short pieces of .080 x .080 (Evergreen 164) styrene to some tape and used a round file to carve out the centers:

Everything was glued to a small length of styrene rod (6.4mm - Plastruct 90864) and a few small details were added to complete the effect. Coincidentally, the rod fit exactly into the center openings defined by the washers.

Here is the gun deck capstan:

I wanted the spar deck capstan to look more like the one on the Hull model in the PEM - more mushroom shaped and svelte in comparison to the stockier gun deck capstan:

Thanks for enduring the process explanation!