Continued on with the weathering process in a big way today so lots of pics in this update! First up I applied an overall wash of roughly 90/10 paint/thinner using Model Master Panzer Schwarzgrau as it's a nice dark gray but not too overpowering. The wash was added to the boot stripe and light gray areas only. This allowed it to do double duty as both a filter and a wash to tie those two colors together.

Then using some clean thinner and various brushes, I adjusted the wash and used it to get the raised detail on the hull and various places to 'pop' a bit more. In some key areas, more of the Panzer Gray was added as a pin wash with a 10/0 pointed brush as needed to produce the desired result.

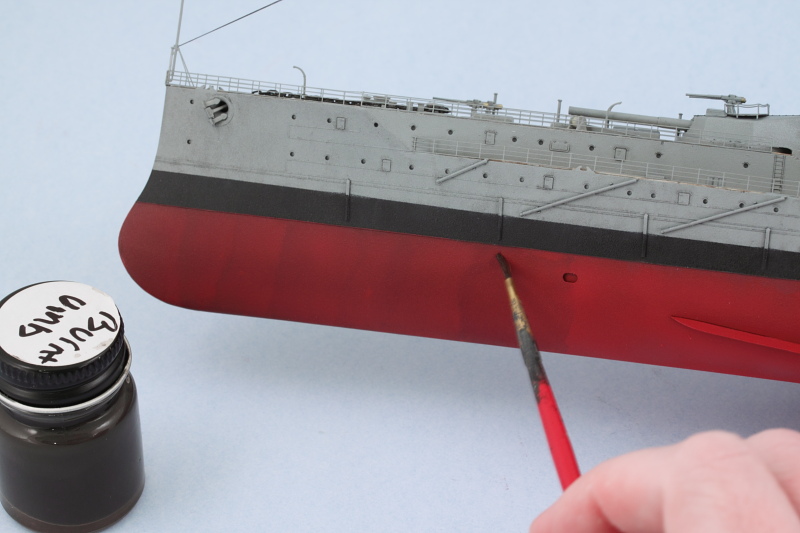

For the hull red areas, I applied a 90/10 paint/thinner wash of MM enamel Burnt Umber.

Because the lower hull has complex curves as well as such a large area, I used the wash as a start point and then made additional adjustments/removal using a square tip blender brush lightly dampened with thinner. This approach allows for some nice streaking effects as well as removing the 'tide' marks that are inevitable when applying a wash over such a large area.

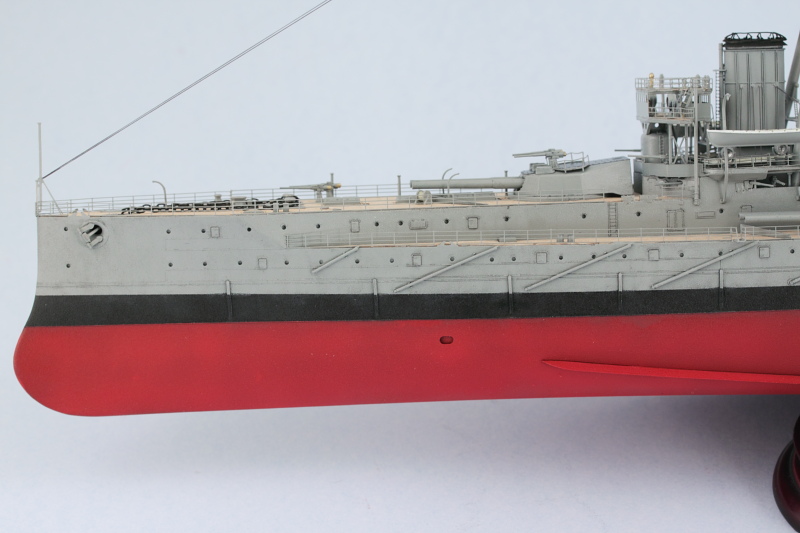

It's a little tough to capture the full effect adequately but the combination of the different weathering adds a good bit of depth to the overall finish. Some residual shine is still present from the protective Future coat and will be dealt with once I'm happy with how everything looks and am ready to seal it all together with a dull coat application.

The 18-inch long hull is a challenge to photograph, but here's how the big girl stands as of now.

I also did some wash weathering on the 'brass' plaque for the stand. The metalizer finish was sealed with a coat of Future and then a wash of MM enamel Gunmetal applied over it to age the finish and provide some depth to the lettering. I used a thinner-dampened q-tip to 'polish' away most of the wash and then used fine point brushes to adjust it further. A coat of Model Master Gloss lacquer in the spray can sealed it together and restores some of the 'shine' to the brass. Another one of those hard-to-capture effects in person but looks pretty good in person, especially once the ship is on place on top of the stand.

I'll let this sit overnight so I can look it over with 'fresh eyes' tomorrow to see if I need to make any further adjustments. Almost done!