Hi,

A few years ago I bought a low cost 3D printer (DaVinci 1.0 from XYZ Printing) and have messed around with doing some ships and related stuff with it. Because it was a low price older model it probably doesn't have the quality of some newer, more expensive units.

Below is a picture of three ships that I have printed (in white) alongside a store bought model of the LCS. All these ships are to a constant 1/700 scale. The larger white ship is a DDG model that I got for free off the internet. I sliced the bottom off the model using some free ware tool, before printing, but printed the rest of the model as one piece. I'm not sure if I had the printer set at its highest level of detail, but the model came out ok, though there are two small overhangs that only partially printed and I ended up stopping the print before it did the masts, because it didn't look like those were going to come out too well. Overall the print wasn't too bad and is useful as a decorative item, but there is some noticeable "layering" along the model where you can see how the individual layers of the print stacked up. If I wanted to try for something suitable for display I would probably reprint it at the highest level of detail, and maybe break the print into parts, and/or also maybe buy some better detail stuff from Shapeways etc to replicate some of the smaller detail.

The middle sized white model is for a notional frigate whose hull and superstucture I built up using some spreadsheets to develop the offsets. I then exported those offsets from EXCEL to a text file and converted from text to ascii format. For this model I printed the hull and superstructure separately and glued them together later.

The smaller white model is for a small corvette sized project I once worked on at work. The model was developed in AutoCAD and another file and I tried printing it out as a complete single piece. If you look closely you can see a band around the base of the masts that shouldn't be there, but got added by the printer software because a some small gaps and/or flaws in my initial CAD file. Similarly the bottom of the ship also got messed up a little due to similar flaws with the propeller shafts etc. In general, based on my experience with this model and the larger DDG, I've kind of concluded that for complex models sometimes it might be best to print larger items in parts, such as maybe separating the superstructure from the hull or splitting the hull along the waterline etc, especially since my printer has an 8" x 8" footprint limit.

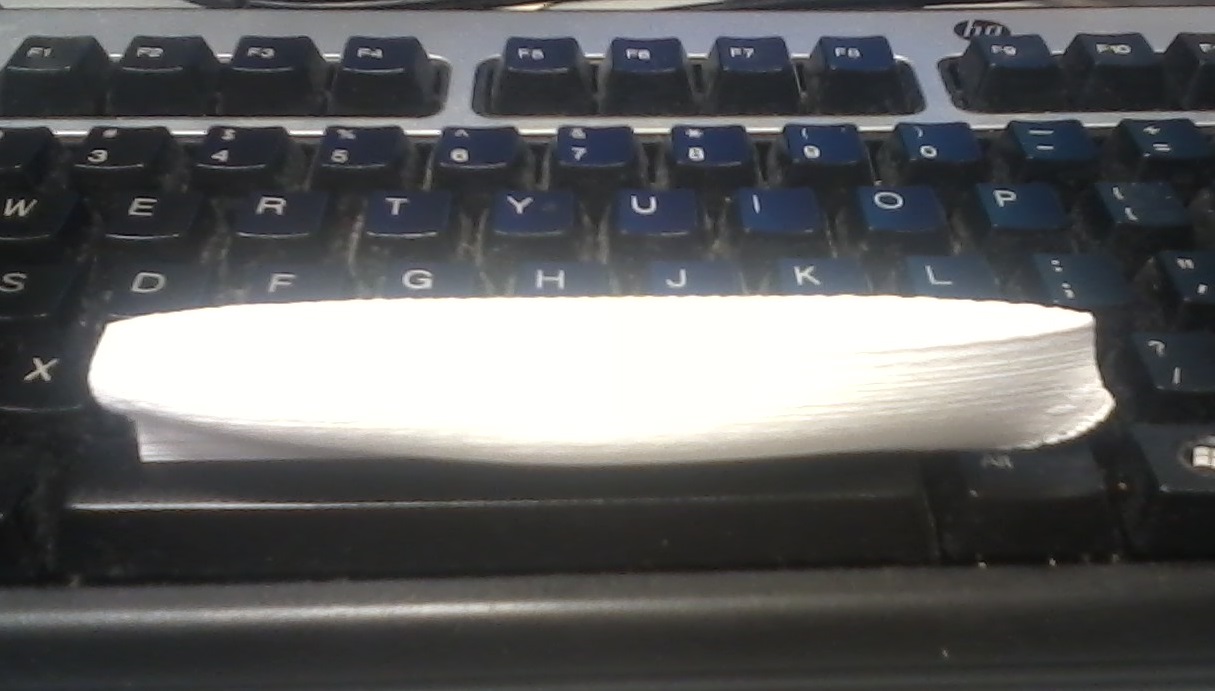

I've also been experimenting with some free software off the internet called Delft Ship that allows you to try and design your own hullforms. Below is an image of a generic Pre-Dreadnought type battleship hull (roughly based on a small lines plan I found on the internet for the Russian Battleship Kniaz Potemkin). I don't believe that the model shown below was to any specific scale, but I have been thinking of maybe trying to maybe do up an entire Pre-Dreadnought to a larger scale, probably doing it in pieces.

Regards

Pat

PS. I think recently the company that the copy that made my printer was recently running a promotion where if you bought a dozen filament cartridges they would give you one of their older model printers (like mine) for free.