Hi,

In addition to what the others here have suggested I have found some luck in using "Balsa Filler" and "Airplane Dope" or "Sanding Sealer". The Balsa Filler is a fairly fine grained paste which can be fairly easily smeared across a surface, and a coating of either the dope or sealer ontop helps lock it in place and fill in the gaps. Though I have found that I often have to do more than one coat and/or some touch ups in some areas, with a bit of light sanding in between.

Here's a link to something that I was working on earlier this year, that I had to set aside for awhile because of work related travel. The sponsons on that model were 3D printed and finished off using the technique that I described above.

http://cs.finescale.com/fsm/modeling_subjects/f/7/t/174726.aspx

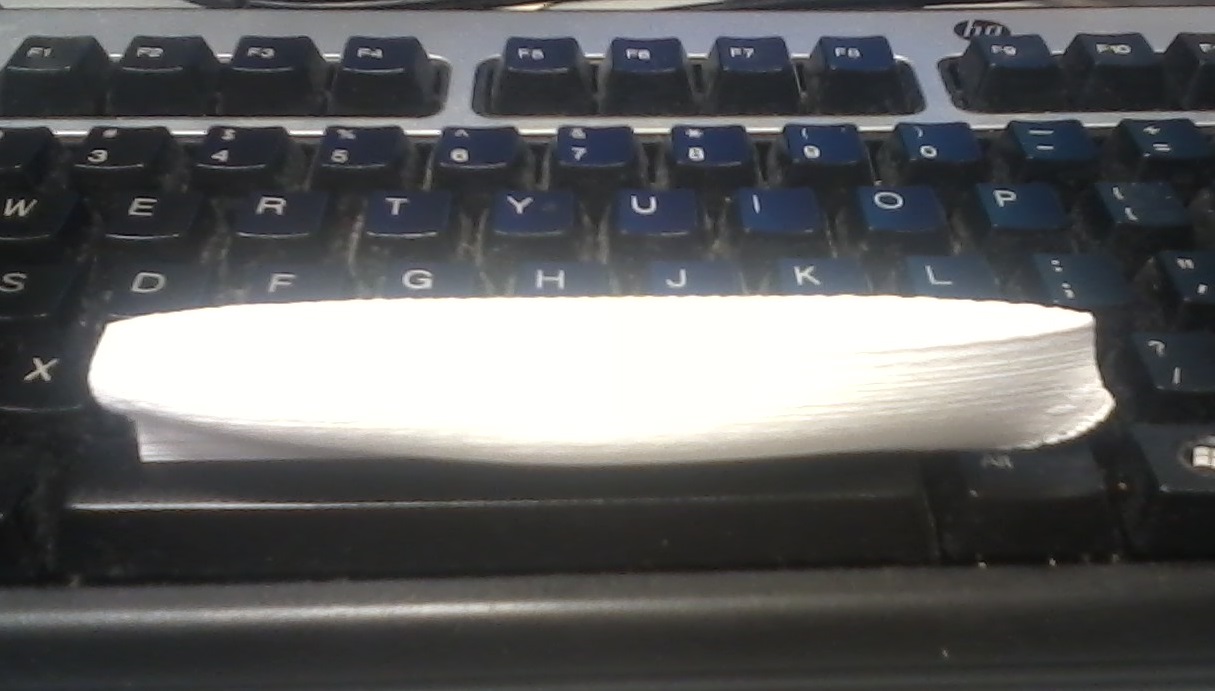

In addition, here is a (slightly out of focus) picture of a small Pre-Dreadnought style hullform that I 3D printed along with a later picture where I had tried filling and sanding the hull. This was one of the 1st 3D prints that I tried to "seal" up and it was a bit of a learning process so it took me a while to get everything to look reasonably OK, though I think that the end results aren't too bad.

http://cs.finescale.com/fsm/modeling_subjects/f/7/t/173994.aspx

Hope that helps.

Pat