Hi friends! Here's how I make scale galvanized sheet metal roofing panels. This works great at the 1/25 scales I use (G scale on trains). Each one with a unique style, color, and pattern yet uniform at the same time. Like this:

1 by Jason Stoots, on Flickr

1 by Jason Stoots, on Flickr

Materials I used are all from Amazon. An artist's oil paint tube crimper, 36 gauge aluminum foil, and the ferric chloride. Gloves, eye protection and ventilation; I cannot stress this enough. This is nasty stuff that gives of toxic fumes. Work outside! Chemical and tools:

2 by Jason Stoots, on Flickr

2 by Jason Stoots, on Flickr

Carefully cut your strips to your desired width. Be careful here as well. These edges are sharp!

3 by Jason Stoots, on Flickr

3 by Jason Stoots, on Flickr

Align your strip into the crimper. It's 3" wide, but I found that it's really hard to keep the aluminum foil straight. I used 2" for my panels and they fed in quite nicely.

4 by Jason Stoots, on Flickr

4 by Jason Stoots, on Flickr

Turn the metal through the crimper. The strips can wander off course as you go, but corrections can be made as you go. Keep as straight as you can. This wore my wrist out. Take breaks!

5 by Jason Stoots, on Flickr

5 by Jason Stoots, on Flickr

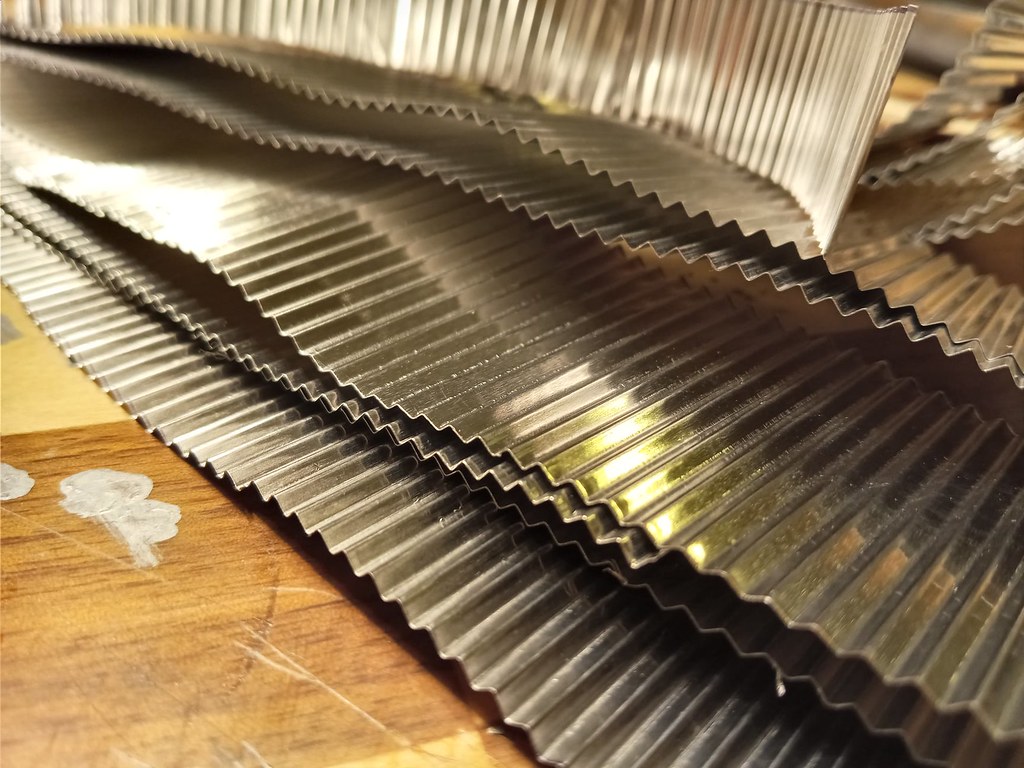

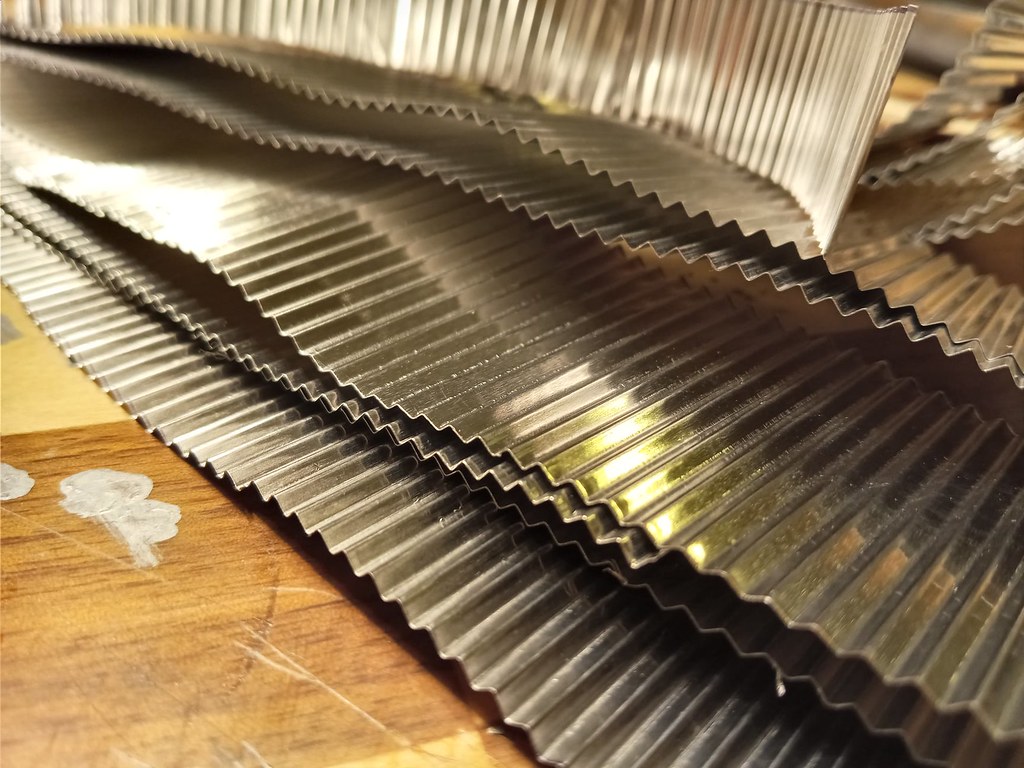

You get this:

7 by Jason Stoots, on Flickr

7 by Jason Stoots, on Flickr

Strips crimped and ready.

8 by Jason Stoots, on Flickr

8 by Jason Stoots, on Flickr

Cut your desired panel size.

8 by Jason Stoots, on Flickr

8 by Jason Stoots, on Flickr

If you have multiple sizes to do, bag them in groups. This will save you some headaches and time re-sorting them after you're done. Make some extras, too. There's a learning curve so you'll want a few more.

9 by Jason Stoots, on Flickr

9 by Jason Stoots, on Flickr

Ready? Time to acid. Top down: first container is just plain water, next two are baking soda/water (to stop the reaction), bottom one will be the acid.

12 by Jason Stoots, on Flickr

12 by Jason Stoots, on Flickr

Pour very carefully. Wear gloves and eye protection. Do this outside.

14 by Jason Stoots, on Flickr

14 by Jason Stoots, on Flickr

Dip the panel. Depending on the outside temp, the acid can attack quicker when warm. It's cold today so I've got some initial work time to test before it starts to get warm; the acid will put off it's own heat from the reaction. The pan above it is neutralizing a test piece.

15 by Jason Stoots, on Flickr

15 by Jason Stoots, on Flickr

About 10 seconds. This will dissolve the panel entirely if not careful.

16 by Jason Stoots, on Flickr

16 by Jason Stoots, on Flickr

Acid 10 seconds, stop the reaction a couple times, put in the last water/soda pan.

18 by Jason Stoots, on Flickr

18 by Jason Stoots, on Flickr

Wash thoroughly. They'll appear black, but really come to life as they dry.

19 by Jason Stoots, on Flickr

19 by Jason Stoots, on Flickr

My test pieces.

20 by Jason Stoots, on Flickr

20 by Jason Stoots, on Flickr

Here we are.

23 by Jason Stoots, on Flickr

23 by Jason Stoots, on Flickr

Hope this helps someone. Feel free to ask any questions. If you try this, be safe.

Thanks for looking.

J