QUOTE: Originally posted by Peridexion

A Jeweler's saw would make short work of this. This is just the kind of task they are made for.

|

|

I can't believe I forgot about that

![Banged Head [banghead]](/FSM/CS/emoticons/icon_smile_banghead.gif)

Oh well you live and learn ... and forget ... and learn again

![Sigh [sigh]](/FSM/CS/emoticons/icon_smile_sigh.gif)

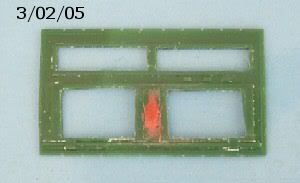

Anyway here is the end result after drilling more holes and tapping a straight edge razorblade (thin) between. It's all messed up but next time jewelers saw.

Probuilder thats a good idea, kinda like a piece of small cable. Where do you get silk thread BTW? Will dental floss work?