Hi everyone,

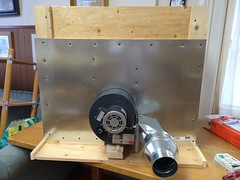

Just thought I'd post some photos of a DIY spray booth I built about a year ago, with a year's worth of use I'm pretty happy with how it turned out. I spent lots of time looking at photos of similar booths online (most of them here on this forum), in particular while trying to figure out how to mount the Dayton blower to the back of the cabinet. I settled on mounting the blower to a piece of galvanized sheet metal and then screwing that whole assembly to some furring strips on the back of the cabinet. The main trick is supporting the weight of the blower from underneath--you'll see I did that with a stack of 1x4 blocks centered under the fan motor. It all vents directly out the back with very little ducting via a window at the same level as the booth.

Materials-wise: I used a 36" wide bathroom sink base cabinet harvested from a salvage shop ($25); 2'x3' sheet of galvanized steel ($20); a piece of lexan on the top in the sink opening ($20); 3/4" plywood for the back, and 1x2s and 1x4s for the furring (all on hand); 6" ducting collar and 6" to 4" reducer ($15-ish?); and of course the blower, which I got new on fleabay for $120 (Dayton model 1TDT2, 549cfm, 1640rpm). Wiring, plugs, switches etc., all stuff I had on hand, plus I'll need to put a light over it. So basically a $200 project, whereas the large Pace booth I might otherwise have bought is $500. The main thing is that I had no intention of skimping on the blower.

Here are some pics:

BEFORE: spray booth base cabinet open

BEFORE: spray booth base cabinet open

spray booth fan mounted to galvanized sheet

spray booth fan mounted to galvanized sheet

spray booth back framed, ready for blower

spray booth back framed, ready for blower

spray booth back with blower mounted

spray booth back with blower mounted

spray booth wiring box

spray booth wiring box

Big box store sells sheets of this 2'x3' filter material, so I stuck the entire sheet right in the back of the cabinet:

spray booth with filter in place

spray booth with filter in place

I'm still monitoring how the airflow goes, if I need to box in a small plenum at the rear of the cabinet, I may do that down the line.

spray booth ducted

spray booth ducted

Spray booth back

Spray booth back

The duct stays all taped up, except where it slips on the fitting near the fan, so I can remove it to close and lock the window when I'm done.

What it looks like from above

What it looks like from above

Anyway, hope these photos help someone else who is trying to build a booth. I wanted a big booth in order to be able to spray built-up structures, and I like a lot of room to work in. Using the bathroom vanity as the basis for the build, this booth certainly has worked out well.

Jim