Making a punch and die set is really quite easy - and it's really inexpensive - you just have to have access to a few tools to make one.

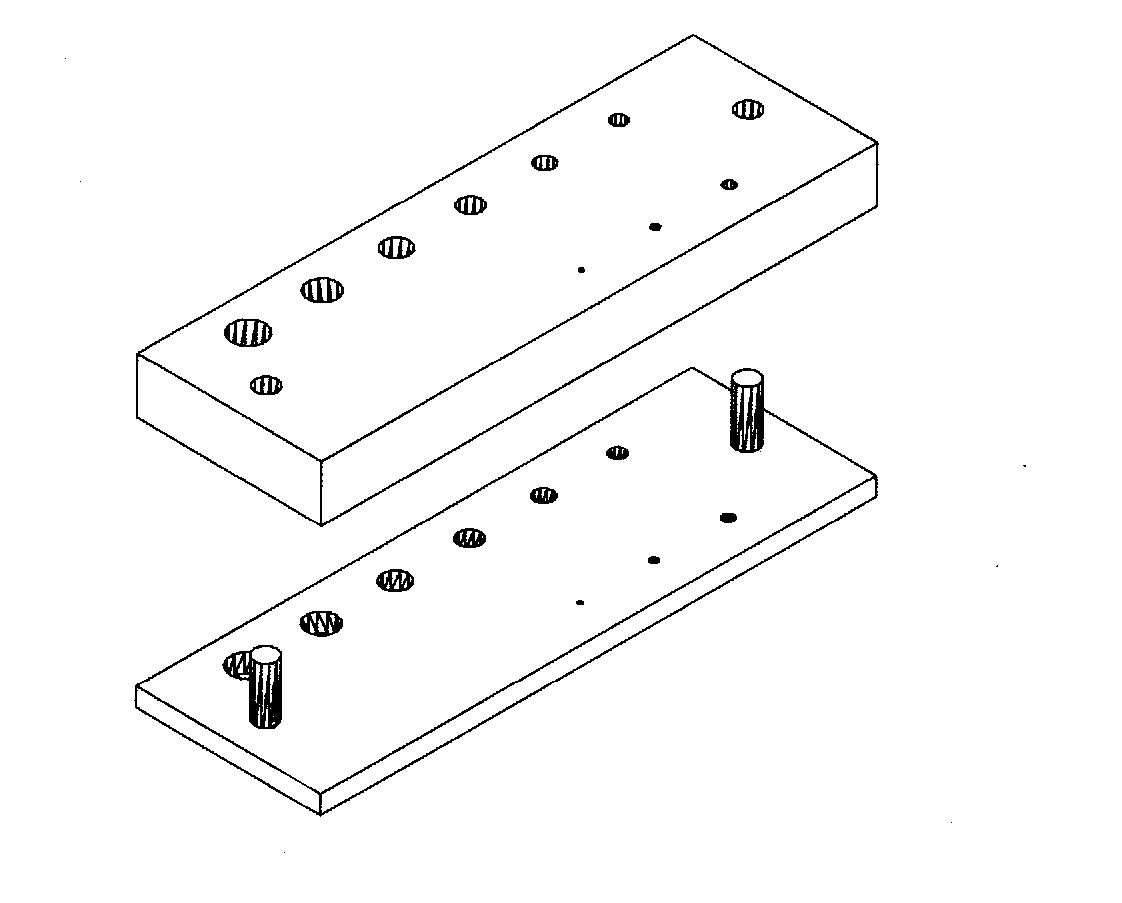

Below is a drawing of one I made a while ago........

Now - imagine the top piece is acrylic about an inch thick......the bottom piece is steel or aluminum about a quarter of an inch thick.

Cut both pieces so that they're the same overall size, clamp them together, and using a drill press, drill two holes in either extreme end right through both pieces. These holes are for steel locating dowels that you should glue or solder into the metal base plate. Make sure the dowels you use are a snug fit in the holes that you drill - just match the drill size with the dowel size.

Once these dowels are stuck fast to the base (making sure the top acrylic block slides on and off easily), and using the drill press to keep all the holes perfectly square to the base, drill a number of holes along the side........from larger to smaller - whatever sizes you need.

Make sure that the drill is set on its slowest rpm setting and work slowly - use lots of 3-in-1 oil or a suitable coolant to help keep the drill tip and flutes cool so you don't heat and melt the acrylic.

Once you have the holes drilled, hit the back end of the drills you just used (to make all those different sized holes) with a fine grinding wheel on a bench grinder to make the ends as perfectly flat as you can get them - with nice sharp edges. These edges, along with the sharp edges on the metal base plate you just drilled, are the effective "cutting edges" - cuz what you're doing is "shearing" the plastic or paper or whatever......by placing the original between the metal and the acrylic, placing the back of the drill into the right hole, then hitting the drill point with a weight.......I use either a plastic hammer or a brass hammer.....neither one will damage the drill tip.

The extra thick acrylic top gives more support for the drill and acts as a "guide" to ensure that the drill doesn't move offline or at a slight angle - the more carefully you make this tool, the longer it'll last and the sharper the cuts you'll get.

I've used a metric drill set to make my punch and die set - they come in 1/2 mm steps from 0.5mm to 13mm.......lots of variety there and a size for any application I might find.

If you have any questions, just email me at the link below - I'd be happy to give you any help you might need.