Snoopy,

I made my own punch and die set - and it works like a charm. Best of all, I made it for almost no cost at all.

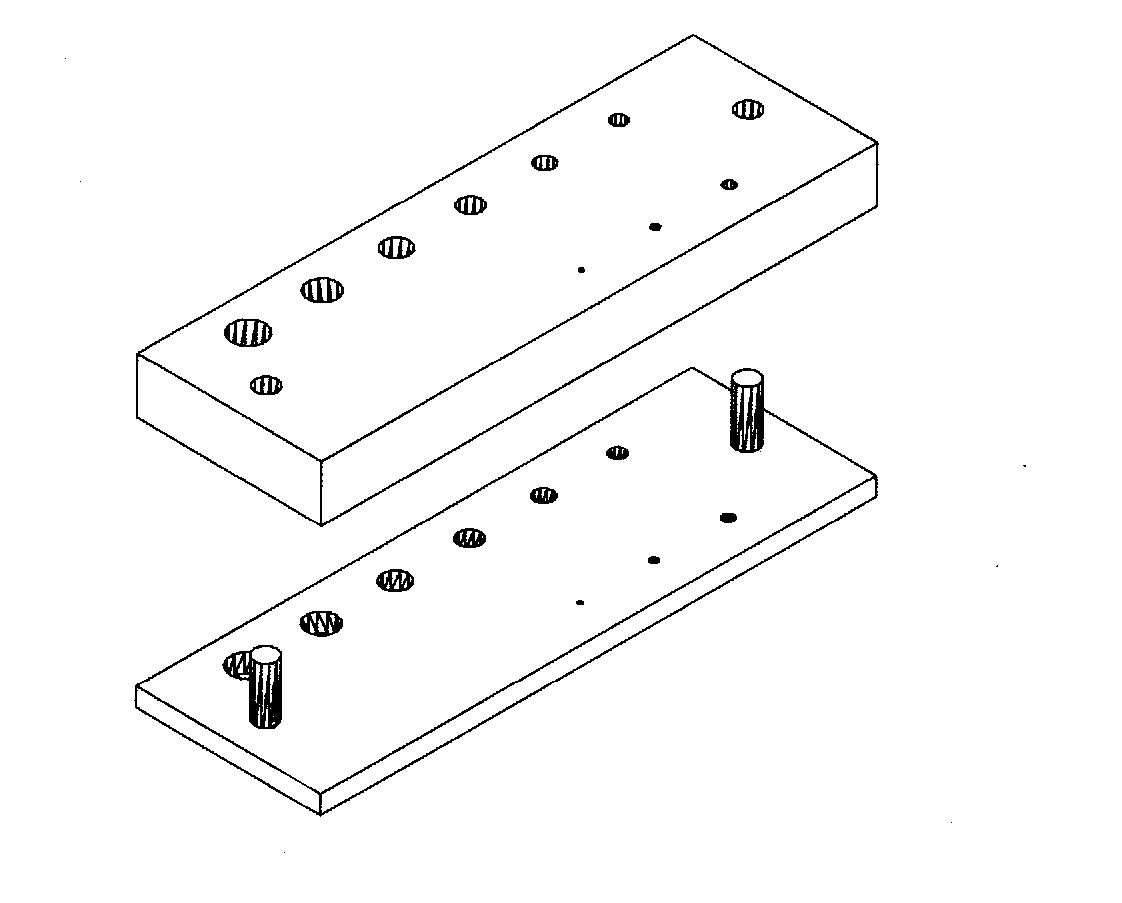

Below is a schematic - I took 3mm perspex, laminated 3 pieces together for the top, and I now have an aluminum base (it used to be plastic) for the bottom.

I clamped the top and the base together, drilled holes in each end (use a drill press!! This is important!!!) for steel locating dowels which were glued into the base.

Once they were located together, I used a stepped set of drills to carefully and slowly drill through the perspex and the aluminum. I used a metric set of drills - they come in 1/2 mm steps. Drill slowly and use a lubricating oil for a coolant to keep the perspex from heating and melting.

Use a drill press to keep all the holes perpendicular to the base. This is important for the longevity of the shear cutting edges of the base.

For the punches, I hit the back of the shanks of the same drills with the fine wheel on my bench grinder to get nice clean, sharp edges......and to use the drills, I have a small copper mallet - it weighs enough to do the job, and is soft enough to do no damage to the drill tip.

Believe me, the set works like a charm, cost next to nothing and has lasted for more than 5 years so far. It's easy to make, too.

If you have any problems, just email me.