Hi,

I have been playing around with both a filament printer and a resin printer over the last couple of years, and agree pretty much with what the others have posted above.

Acouple ofadditional points include, that in general there really seems to be a couple different ways to implement 3D printing.

- You can go online to sites like Shapeways and see if anyone hads already developed a 3D model of what you are looking for and pay to have that model printed

- You can buy (or download a free) 3D software package, learn how to model in it, and develope your own 3D model, and then send it off to a company to have it printed.

- You can buy (or download a free) 3D software package, learn how to model in it, and develope your own 3D model, and then buy your own printer to print it with

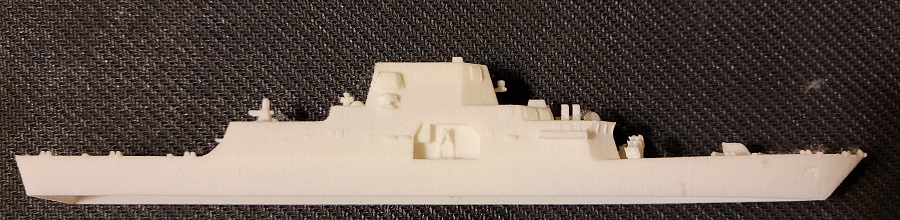

Each option has its own advantages and disadvantages, and you might wanto to play around for a bit before diving in too deeply. A big advantage of using a professional printing service instead printing something yourself is that often these large companies have top end printers capable of very high quaility/detail, though it can be pricey to get something large printed. Below are some pictures of a 1/700 Lockheed Martin LCS/FGG propsal, as well as a 1/350 scale model of the actual FFG that is currently being built for the USN, that I bought from Shapeways.

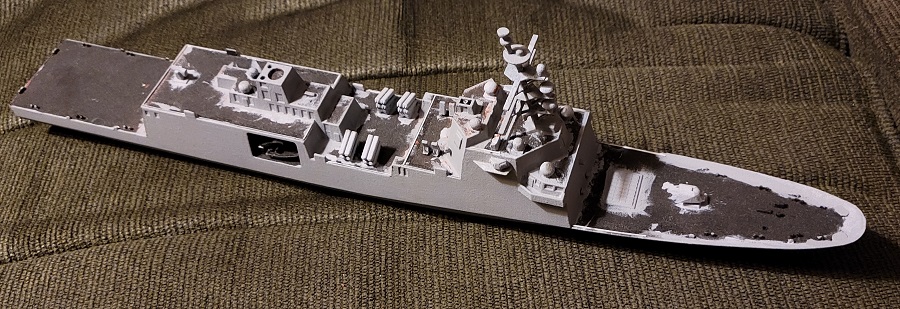

Also, here are some prints that I did for a couple 3D armor models that I got off the internet printed to 1/72 scale. The green one is an XM-8 Mobile Gun System prototype and the brown one is a Covenanter WWII era British Tank.

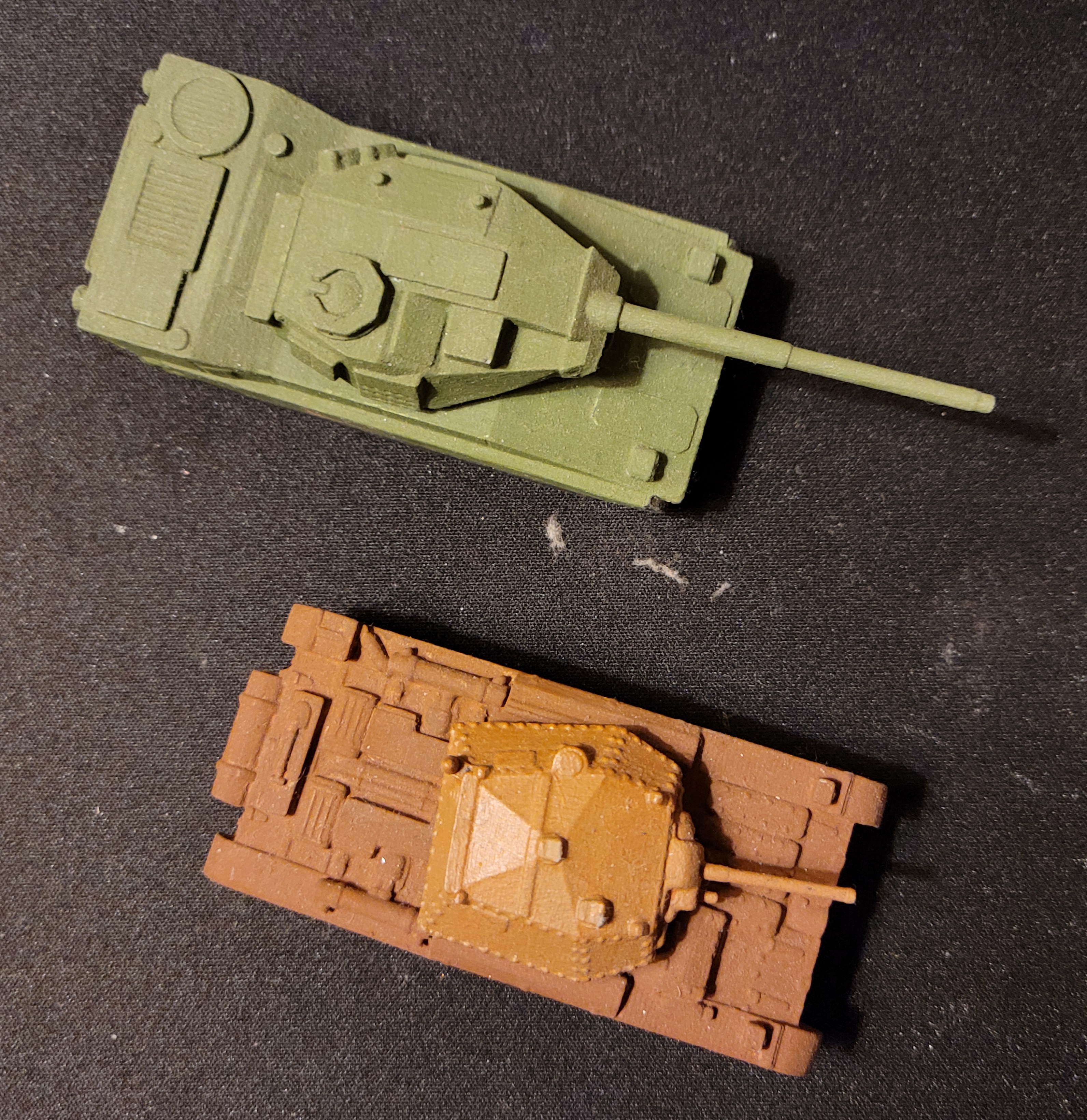

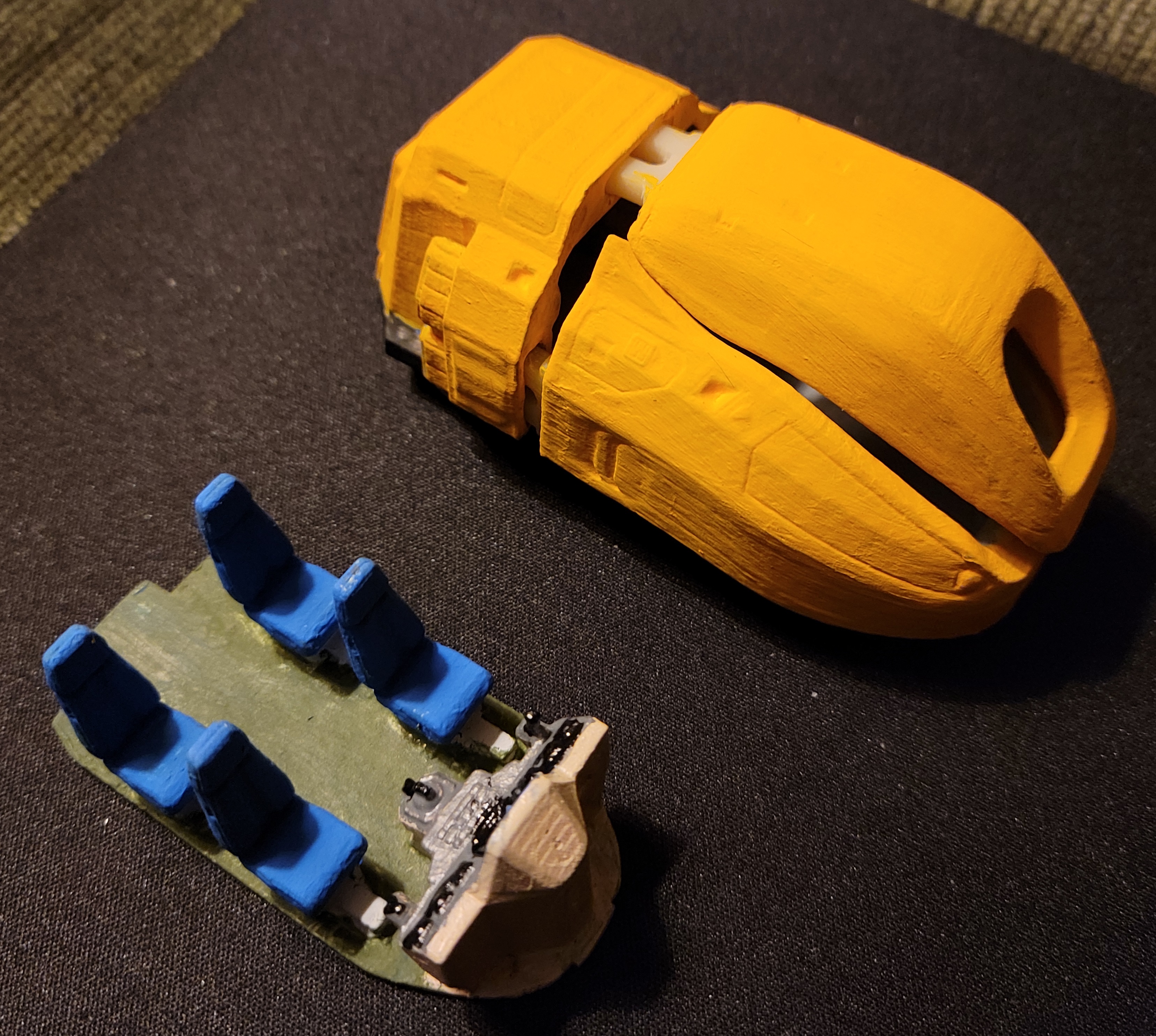

Below, also are a couple builds of 3D models that I have bought or downloaded off the internet. The little yellow one is for a scifi type escape pod that I bought off the internet for just a few dollars. The orange and biege one is for a WWI era unmanned flying bomb called the "Kettering Bug" that I am making for a Group Build on another site (sorry that I haven't finished painting and assembling it yet).

The 1/25 scale figures include a simple 3D figure that I downloaded for free that I am using to represent a civilian ship crewmember. The soldier is a WWI figure that I bought for a small amount to go with me "Kettering Bug" model. And the 3rd (unpainted) figure is actually a 3D figure I kind of "made" using a program called Daz Studio. In it they have a default male and female figure that you can "tweak" in various ways and/or buy add ons for. It also has a "limited trail" feature where you can upload an image of someones face and it will tweak the model to try and match it. You have a limted of only 4 or 5 saves, before you have to start paying for that feature, but I went ahead and tried out a picture of a character from some 3D Japanese carftoon to see how it came out, added some generic clothes models that I bought off their site and 3D printed it just to see how it turned out.

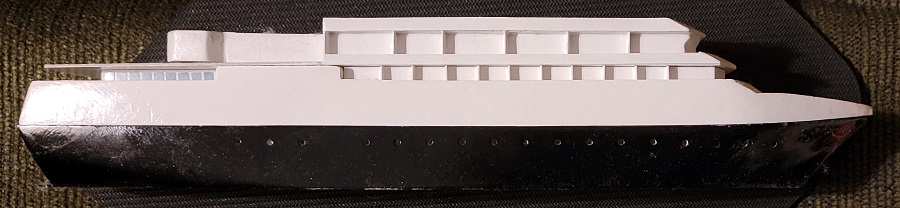

And finally, here is a model that I developed myself for a small cruise ship that I started printing on my old filament printer, but ended up not finishing (at least not yet) since I wanted to revisit how to do some of the details now that I have my newer, higher resolution Resin printer.

Anyway, As I noted above, there are several options to consider when getting into 3D printing and it may be worth investigating each of the options, such as seeing if anyone has already made a 3D model of some of the stuff that you are looking to build, maybe buying an existing 3D build from someone like Shapeways to see if it has the level of details that you are looking for, and/or downloading a free (or low cost) 3D CAD program to see how well you pick up how to use it, before making the plunge into buying a printer yourself, espacially since improving technology means that stuff that comes out a few months from now could potentially be a slight bit better than what is available now and/or if something new and improved comes out, you may be able to snag "last year's model" printer at a potential discount.

Hope that helps.

Pat