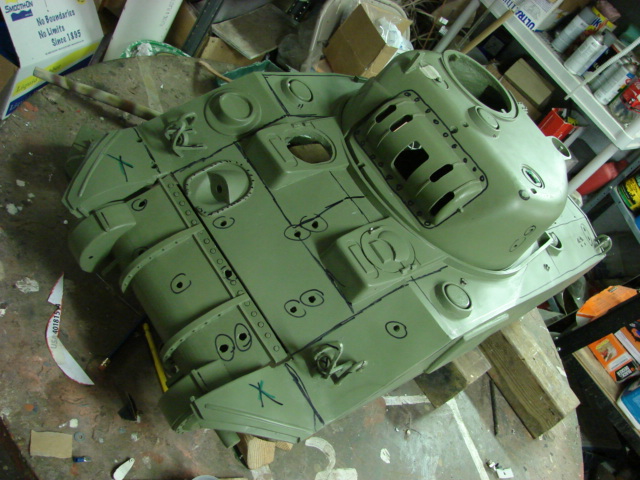

Hi Guys, Now that I finished off a batch of German tanks I decided to build some more American tanks. First will be this old Viper Sherman Hull and turret that I recently acquired in a trade.

For those of you who are un familiar with the Viper Sherman it was an all resin and fiberglass early production M4 Sherman that was released in limited numbers back in 2003. The Model itself is a scaled up copy of the Tamiya 1/35th scale early production Sherman. The model came with a two piece upper and lower hull, non functional VVSS suspension, and lots of crew equipment that would be inserted into all of the holes that are drilled into the tank's surface. The problem with these models is that their resin construction made them very fragile and prone to damage. They also became unpopular because of their weight. Viper soon folded after the release of their Late Tiger I kit that was very un popular because of the same reasons.

I always liked their M4 and I have built two of them when they were released. After building my two Shermans I saw room for improvement, and in making the tanks more rugged and robust.

One problem that the kit has is that the lower hull doesn't have the hull sponsons. The hull is also molded that the hull wall is lower than the sponson by 1/2 an inch. Because of this there is a huge gap that can be shows through to the other side of the tank.

To correct this I cut several pieces of 1/2 inch plywood to construct the sponson and hull wall extender. I used this thickness of material because I wanted to use a material that was the same thickness of the tank's hull, also because it gives me a stronger point to attach fasteners. The sponsons had to be very strong because they will also be used to attach the top hull and the bottom hulls turning them into one solid piece. This alone reduces the fragility of the tank immensely. The sponsons were attached to the tank via fasteners, then they were treated and reinforced with fiberglass cloth and resin.

Prior to in the upper hull installation I reinforced the entire upper hull with more fiberglass cloth and resin. The tank does have cloth imbedded in its casting, but I felt that the thickness was too thin and the extra cloth and resin was a good measure. The Hull now sounds more "Solid".

The upper Hull was attached permanently to the lower hull with fasteners, fiberglass cloth, resin, and epoxies.

I will not be using the stock Viper VVSS suspension. In it's place I will be using my own functional VVSS suspension. Because of this I plugged up the holes for the kit supplied suspension with casting resin. I also used the casting resin to plug up all of the equipment holes.

The tank came with a few tools and other accessories molded in shovels, fenders, head/ tail lights...ect. These were all removed and new ones will be added in their place

The tank's turret also had it's extra armor molded in. The problem was that the kit has the armor placed too low and had to be removed

I will also be tooling up some new Resin components, as well as updating some of the older ones with newer tooling.