I'm just about done screwing around with this model. It's reaching the law of diminishing returns. That being said, I wanted to try one more thing... I had drawn some near scale hood hinges directly over photos of 66 Fairlane hood hinges, and made patterns of them to eventually fabricating them.

At first I was going to make them entirely out of styrene, but quickly added photo-etch fret brass for some of the bars. The end product while technically correct, are not operable due to the flexiblility of the styrene parts that I did use.

I had made multiple copies of the image so I could cut different parts out from the same drawing, since the act of cutting one part destroys the drawing of the part to which its connected. I put some pressure sensitive adhesive on the paper and stuck it too thin styrene sheeting.

I used plastic pins made of 0.025" round Evergreen styrene rod. That was another reason why it really can't operate. The pins are simply not strong enough or mounted strongly enough to be workable.

The smaller links are brass. I CA'd the pins into the non-movable part and used a heated small screwdriver to rivet the other end after it was assembled. I came up with a very easy way to heat the screwdriver tip... just grab it with the resistance soldering unit for a few seconds. I found it easier to drill the PE brass while it was still captivated in the fret and then cut it to length. I meausred the hole spacing with a precision dividers. Holes are 0.026" so the plastic pins are a slip fit.

All the plastic parts were cut out with an Xacto.

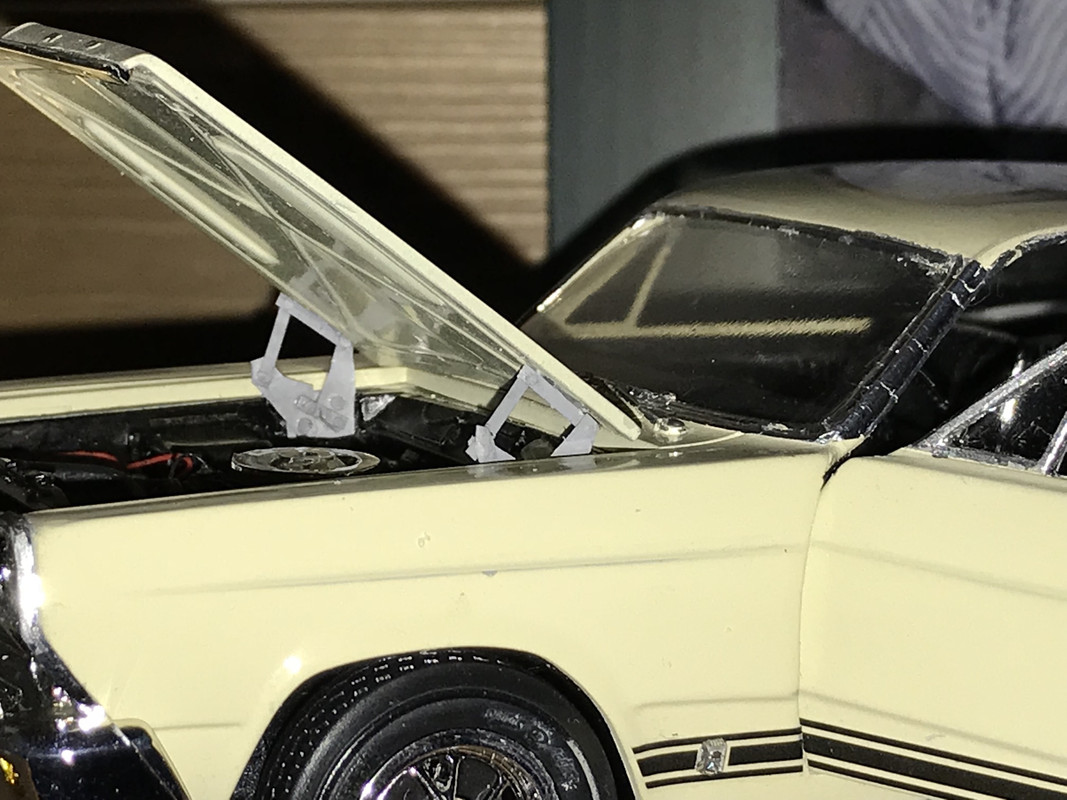

It all went together nicely, and I used thick CA to join the hinge to the sides of the engine compartment. I put them in the up position and then CA'd them so they didn't budge.

The hood was CA'd to the hinges. It's now sitting at a realistic angle with the back edge elevated above the body as it should be with a parallelogram hinge. If I were to do it again and wanted them fully operable I would make them completely out of brass with the pins soldered to the non-moving parts. I would also make the upper bar that mounts to the hood out of angle stock. That will have to wait for the next car I make. And I didn't even think about putting that humongous spring in the assembly. I would also do something to fake that as well. However, it looks pretty convincing.

I had to estimate the actual size that this thing really is since I only had a photo of the front and back from an eBay listing from which to figure its sizes. I made three different size drawings with this being the smallest. It's still a little big since in the full-down position, the hinge extended to high and the hood wouldn't have fully closed, which is the other reason it wasn't going to be operable. Would I do this again? Probably. Hood hinges are very visible vs. the door hinges which are difficult to visualize on a real car.