Time to install the metal foil.

I have used Bare Metal Foil on my car models, but have never used it as large panels on an airplane. So we will see how this goes.

First we need some tools for installing foil; which includes many sharp #11 Xacto blades, a straight edge, tooth pick, Q-tip, tweezers, a tool for making the rivets, a paper blending stick, and #0000 steel wool. Don't forget you magnifing glasses.

Number one rule is to have your work space super clean and wash your hands frequently. The smallest bits of grit or dust that are under the foil will ruin the foil job. Clean fingers will eliminate finger prints on the foil. Also make note of the natural grain of the foil. The grain runs the long diminsion of he foil. Each panel on the aircraft will need to covered in a single sheet of foil.

I will be using two types of Bare Metal Foil, Matte Aluminum and Improved Chrome. Most of the panels will be covered in Matt Aluminum.

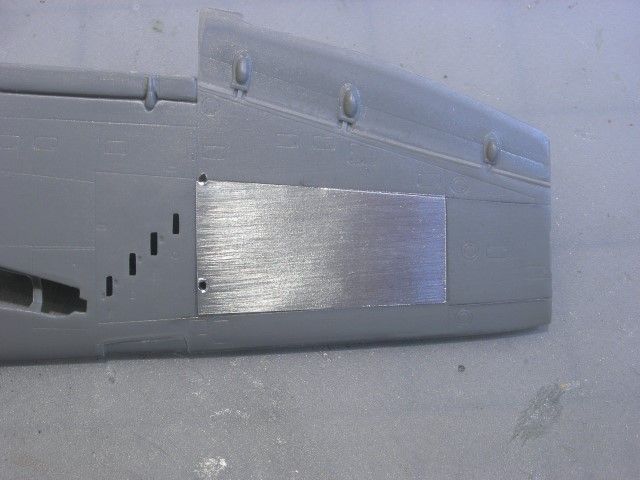

First, place a piece of foil over a fuselage panel that is larger than the panel. Gently smooth the foil with your finger. I know that this looks like a mess, but the foil will be made smooth by using the paper blending stick.

Next, use the paper blending stick to remove the wrinkles from the foil. Just run the blending stick over the foil in the direction of the natural grain (left to right in this instance) and all the wrinkles will be removed. Use the tip of the blending stick to enhance the recessed panel lines.

Next, use the Xacto knife and a straight edge to trim the foil along the panel lines. Run the #0000 steel wool in the direction of the natural grain to enhance the grain. Run the steel wool in one direction only. The grain should be straight. If you run the steel wool back and forth the grain will not be straight. In the real world, all aluminum sheets have a grain pattern.

The next panel was applied with the grain running 90 degrees to the first panel. However; I suggest that you run the majority of the grain in one direction only, otherwise the wing will look like a checkerboard. The steady hands of a surgeon and the paitence of an angel will produce the best job. This is very tedious work. All panel lines need to be tight and straight. Replace your Xacto knife often. A dull knife will rip the foil and pruduce a jagged edge.

I'll use the rivet tool when all the foil is installed on the wing.