Well... Today's the day that you can see it "all finished up". The echo cardiogram was early this morning so I had a long work day in the shop. The test proved at least one thing... my "heart's in the right place" literally. Other than that from what I could see, my heart is working. I didn't see any blood flow going through valves in the wrong direction, but the tech didn't tell me very much. The doc has to do that. Watching those valves opening and closing I was awestruck thinking about how many times they done that in my 71 years and came up with a number of over 49 billion times.

I have a ton of pics today so bear with me.

The "work" day started with touch up painting any areas where the masks leaked and then installing the torpedo and the bomb bay doors. Leaving them off to the end was a good idea since they're in the way and would be knocked around a lot.

I painted the brake lines, removed the masks around the oleo struts, and installed the running lights at the wing tips.

I then moved topsides to get the glazing installed. I used Formula 560 Canopy Cement exclusively for the clear stuff since it dries clear, doesn't fog, wipes off without damage when it's not dry. The windscreen went it without any difficulty. Since it's a slow-drying glue, I taped the parts until they set (about an hour).

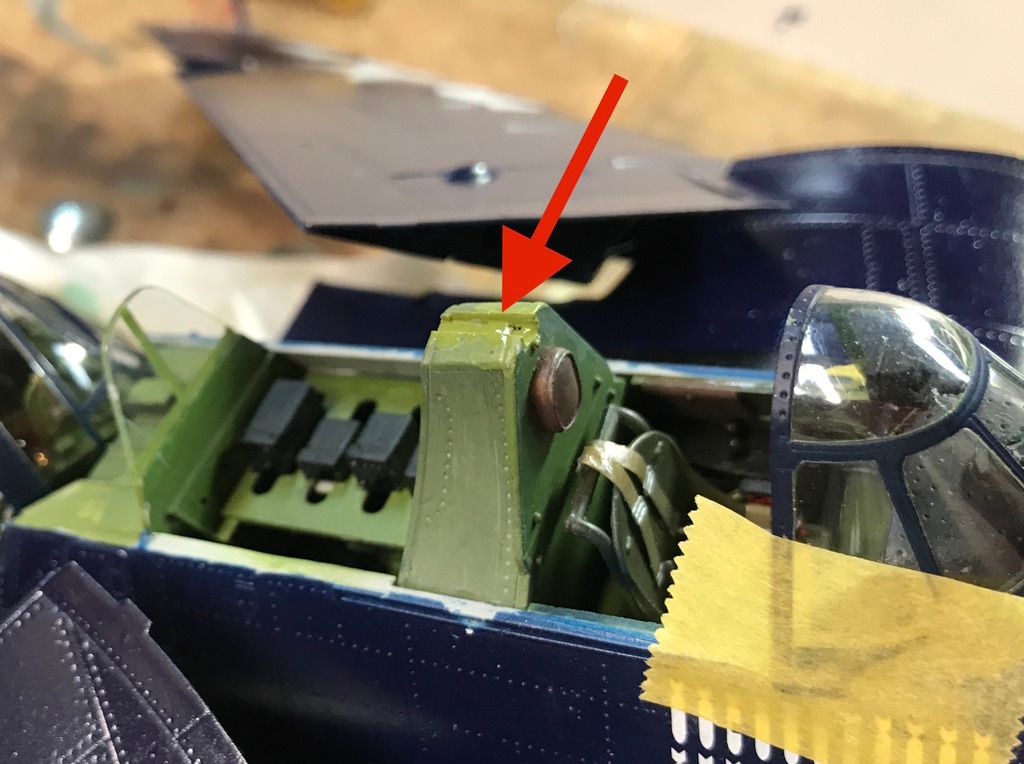

The above also shows another mod. Whenever you add reinforcement to a model part, there's always the chance that it will interfere with something else. In the case of that brass bar I added below the mid-canopy slide impinged on the armor, roll cage behind the pilot and wasn't letting the canopy seat down on the fuze rails properly. So I had to cut a groove in the roll cage without screwing anything else up. I used that new, fine-tooth razor saw to rough out the trench and cleaned it up with an Xacto. It worked and the rest of the canopy array settled down nicely.

The gun turret dome isn't glued. It snapped in place so nicely that I didn't put glue on it at all. No glue is the best way to prevent glue smears. I touched up all the blue areas adjacent to the glazing and added some clear Future on it. I also used brush paint Tamiya clear flat on the walkways on both wings.

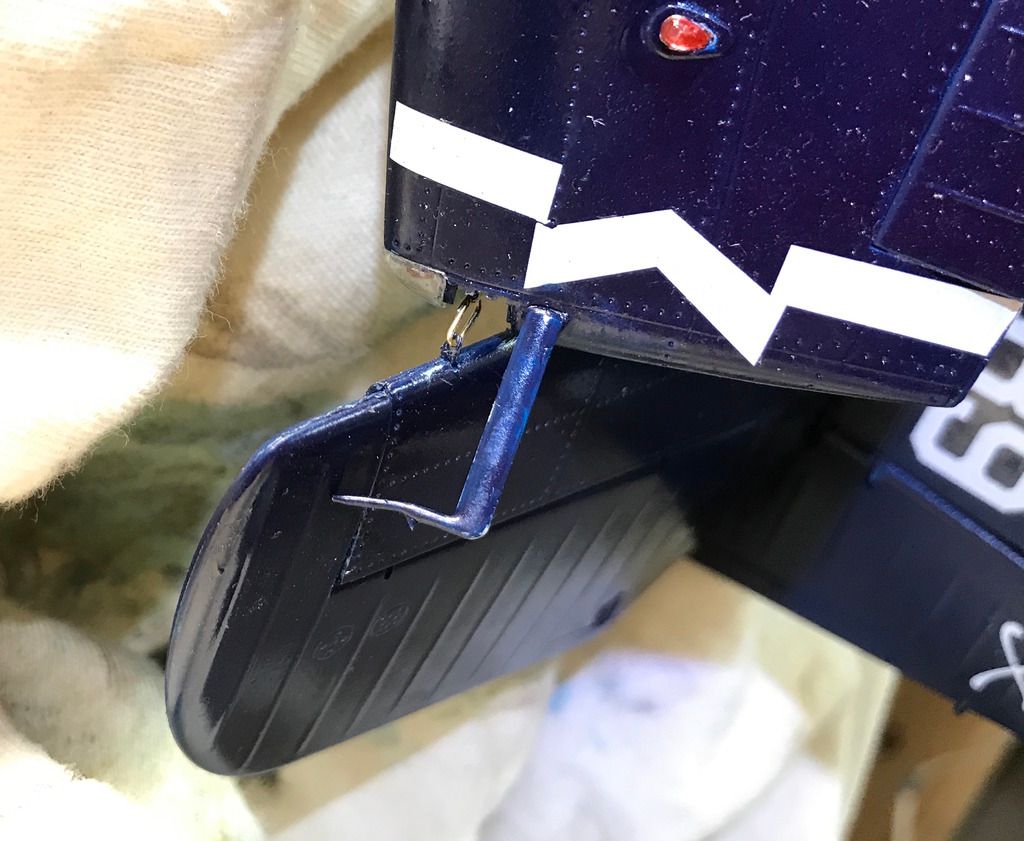

It was time to fold the wings. Instead of using the fat string included in the kit, I made some clips with brass wire. I painted them flat black. Probably not prototypical, but it's very secure.

It was time to glue in the Wright R-2600. I scraped all paint from the glue area, and decided to use 30-minute epoxy for a) strength and b) ability to reposition with the longer curing time. I carefully mounted the plane in my Panavise turned on the side and c-clamped to the work bench. After placeing the engine, I put the cowl on top so it was positioned correctly, and let it set.

When the engine was set, it was time to permanently glue on the cowl. To get it to sit down tight, again, I used epoxy and added some weight for a "Gravity Clamp". Again, after curing it was on for good and reasonably in line. Not perfect, but reasonable.

I needed something to encircle the engine's gear case with something so the weight was on the cowl, not the engine. A Tamiya spray can lid served this purpose.

With the cowl on, all that was left was the prop and the radio antenna. Like the B-17, I used E-Z Line for this purpose. The beautiful thing about this product, besides its elasticity, is that it is intantly adhered with CA. It allows you to intersect lines at 90 degrees and with a tiny drop of CA it's adhered and can be trimmed very close.

So here's the finished model taken in a better photographic environment.

Some weathering powders on the wheels, tires and exhause area is all the weathering I did. It's a newly restored musuem bird so it's clean and fresh.

Well that's all folks. Thanks for hanging in since the beginning.

The next project up is a large Plastruct petrochemical refinery that will be for the railroad. Since it's a plastic structure perhaps I'll post the build here and in the model railroad sites that I feature.