Thanks guys,

doog, All of the builds that I post are in my personal collection. Once finished I store them in my shop, or anywhere else I can squeeze one. typically I keep them covered with tarps to keep the dust off.

wbill, The wheels were very challenging to design, but were also fun to create. it is a good feeling when you spend lots of hours designing, machining, and molding a component to see it come together in the way you designed with no hick ups.

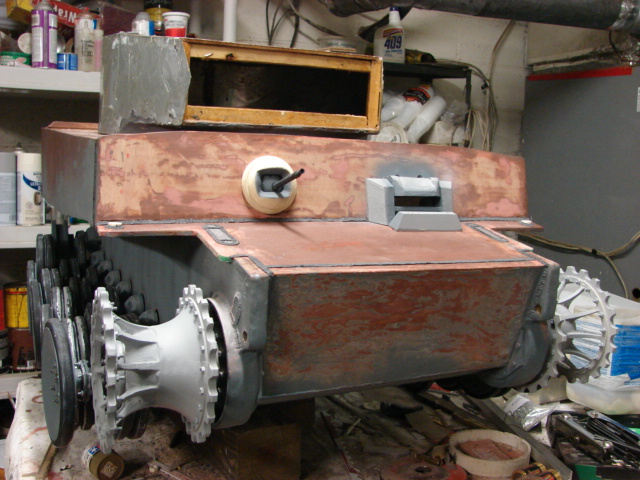

I have made progress on the tank's upper Hull.

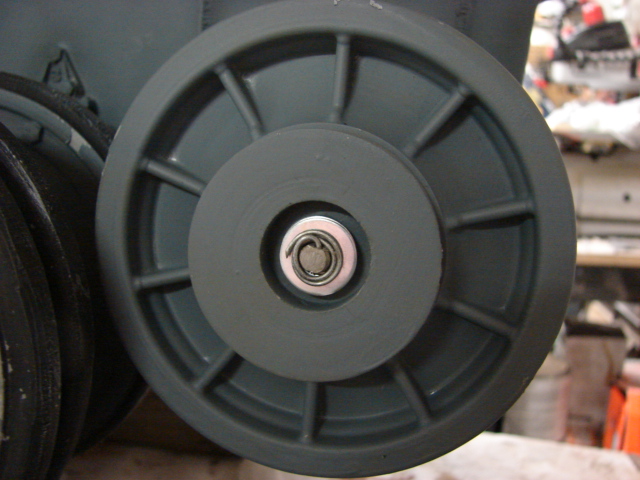

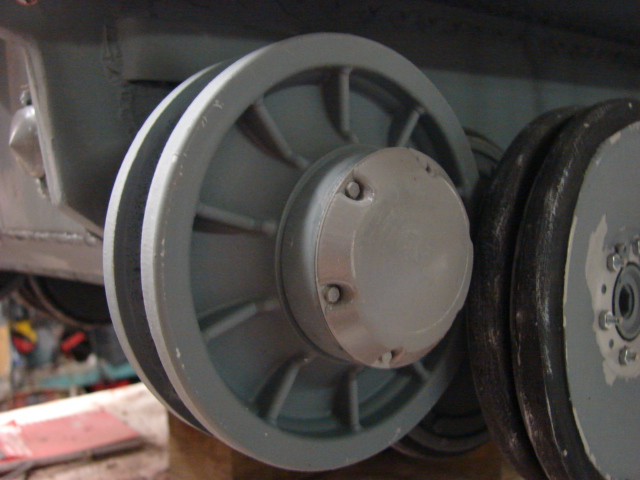

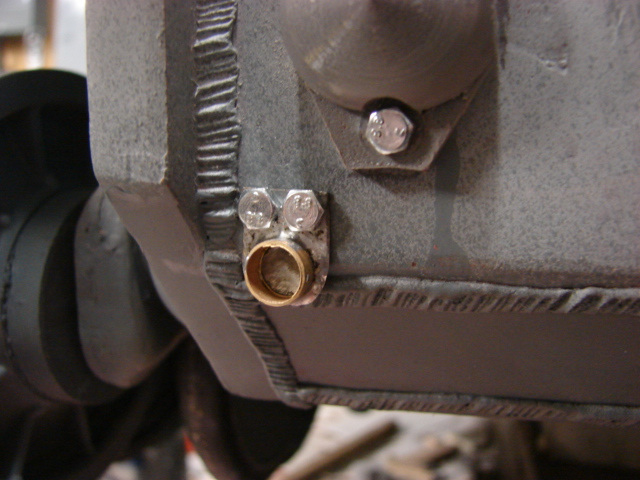

The tank's sprockets and Idlers have been fitted. For the tank's idlers I modified a pair of FOA ABS plastic idlers.

For the tank's idler mods I had to delete the rear molded in hub cap, and to carefully remove the molded in front hub cap. The wheel was filled with resin to make it a solid unit. Once solid I was then able to bore out the recess for the retaining bolt system. two resin and PVC discs were added to the front portion and the rear portion of the idler. The discs give the proper protrusion of the idler hub cap.

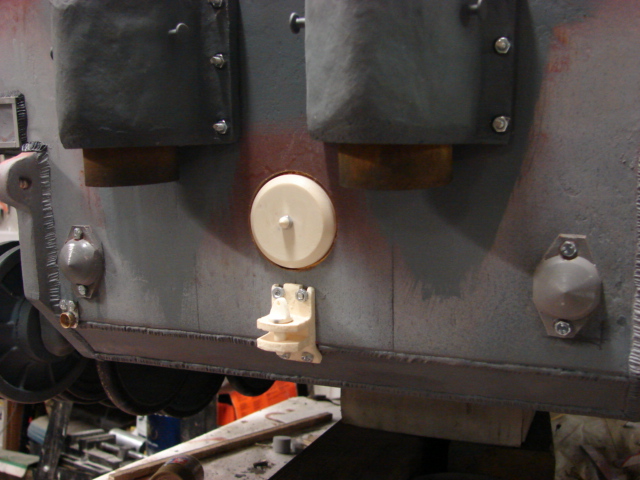

To mount the idler wheel I used the same lock pin system that I use on my other builds. The system allows for the wheel to be mounted securely, but also allows the wheels to spin freely.

Progress was made to the tank's front armored plate details.

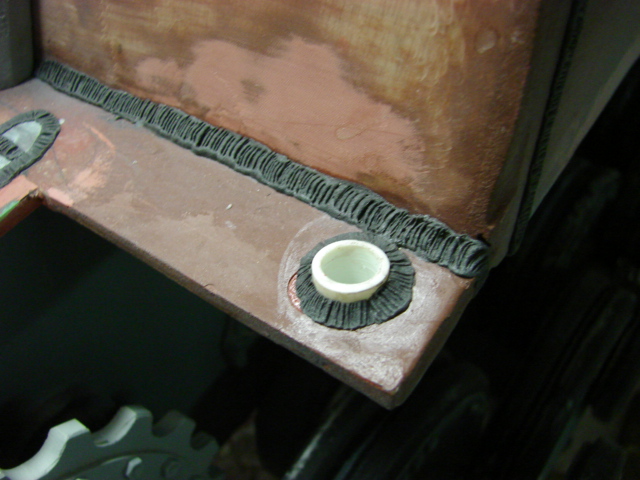

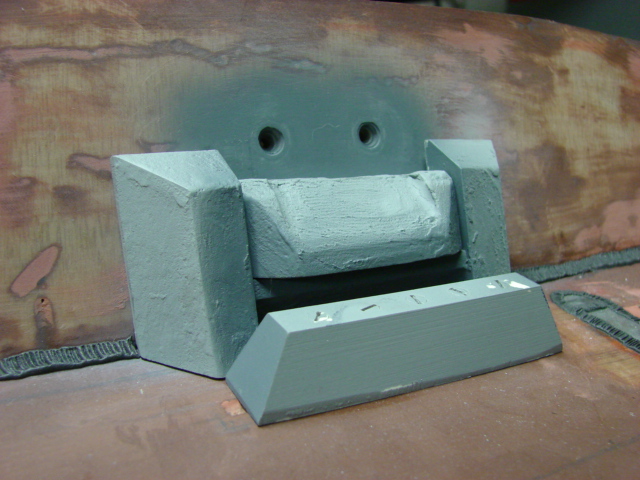

All of the plate welds have been added, and the front plate bosses were mounted

The tank's driver's retracting visor assembly have been mounted.

A small piece of lexan was mounted on the interior to simulate the panzer glass.

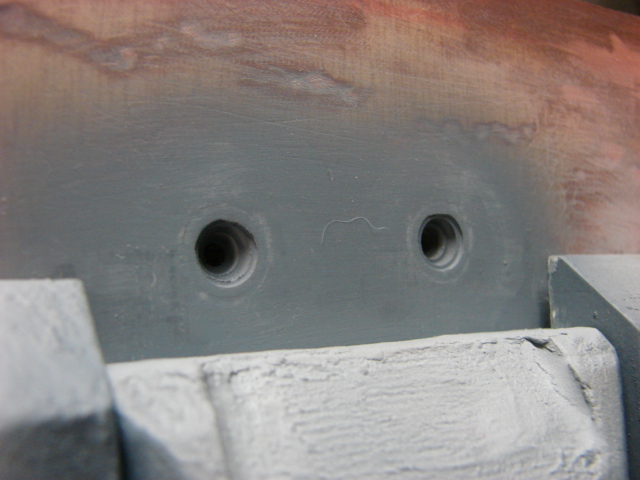

The small back up vision ports were mounted. The mounts have their recessed reduction ledges machined in. On the later production tigers these vision ports were welded shut.

The tank's bow MG ball was also mounted. the bow mg can pivot, and for the MG barrel I used the resin panzerwerk set.

Because I will be making the tank's snorkeling equipment I will be fabricating the bow MG cover. Because I will be making the cover I needed to do something special with the bow MG. Rather than making the MG barrel removable I decided to make the barrel retract instead. The barrel is spring bound and locks into tow positions. One exposed for standard display, the other in the retracted position for when the cover is added.

progress was also made to the On the tank's rear hull details.

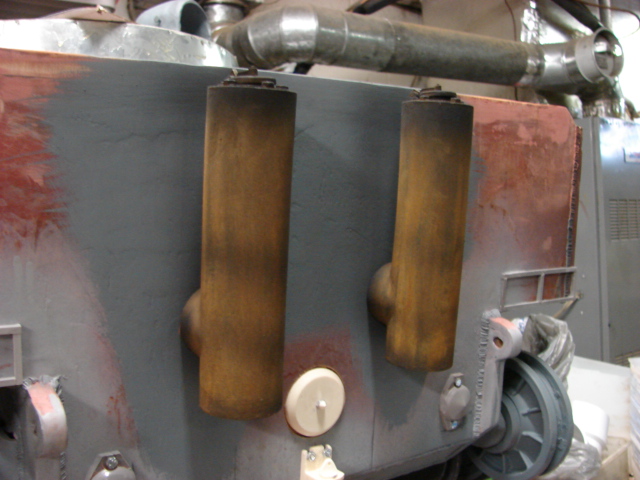

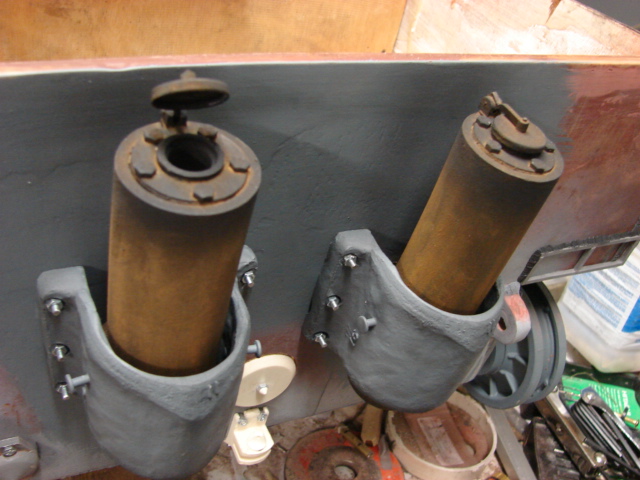

The tank's exhaust stacks were completed, painted and weathered.

Because this model is an initial production version of the tiger the exhausts don't receive the cage guards that are present on later vehicles.

Prior to installing the stacks The tank's hull was prepped with the base coat and the weathering.

After the prepping the stacks were added.

Along with the exhausts the idler tension cover caps, fender mounts, rear reflector mount, engine starter cover cap and tow hitch.

a project update video was also uploaded to youtube.

http://youtu.be/Ds0cvpCHkOM

I will now be focusing on completing the tank's rear details like the fenders, tool boxes, tail light...etc. More progress to follow.