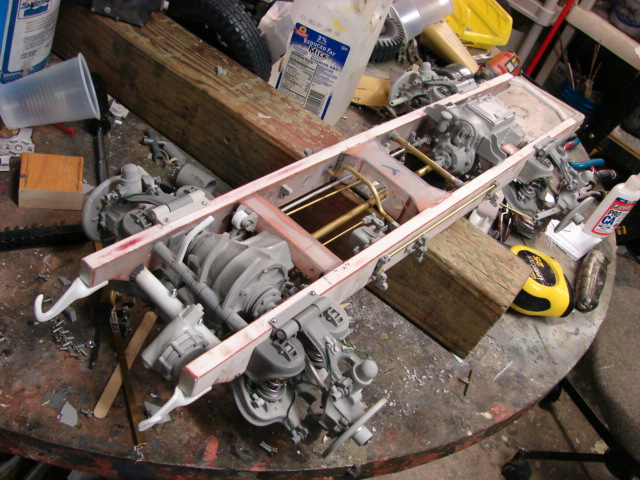

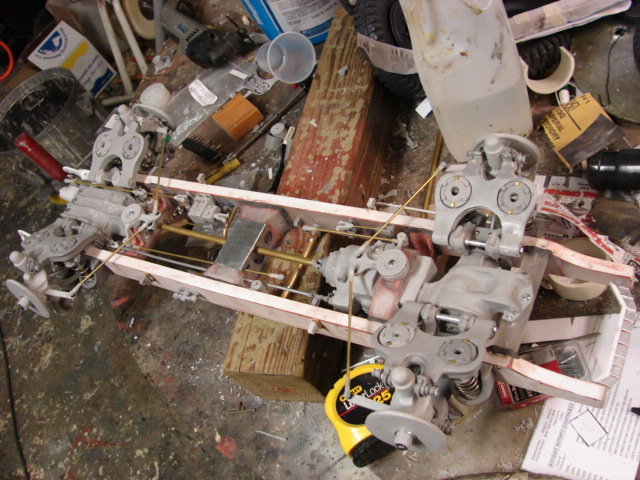

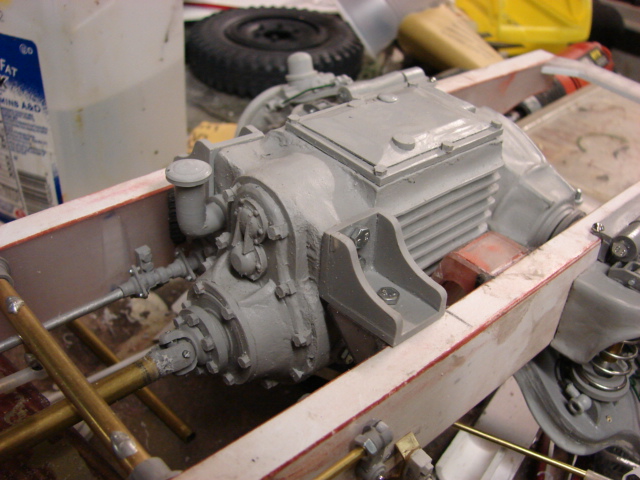

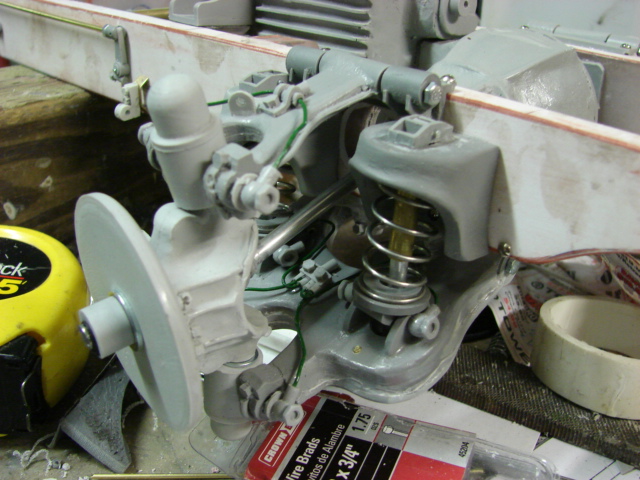

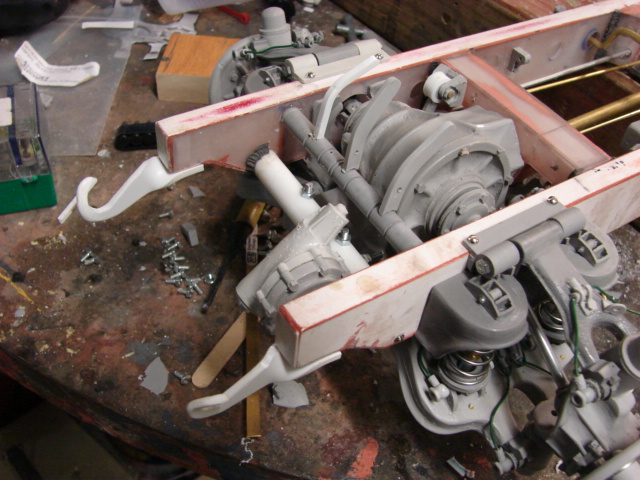

I have made more progress on the 222's chassis.

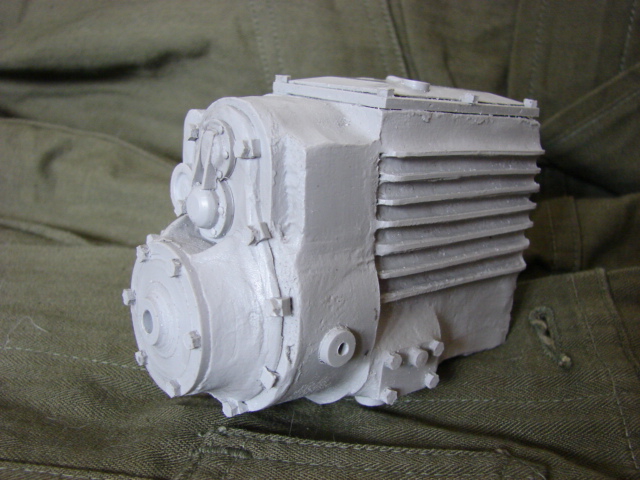

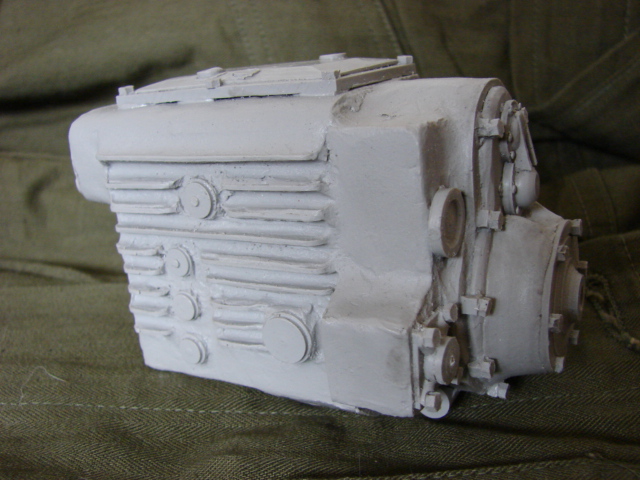

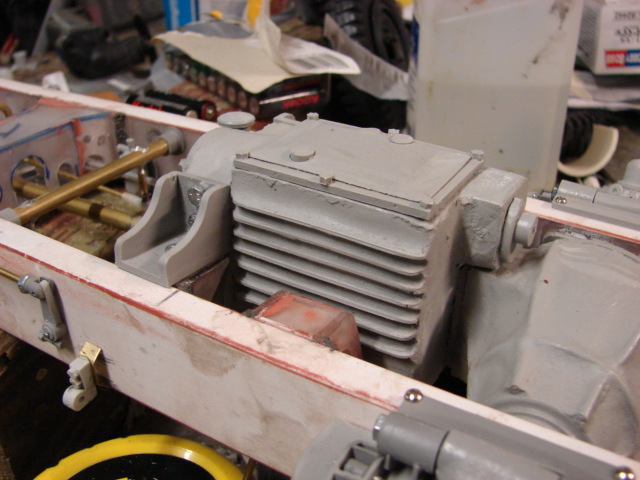

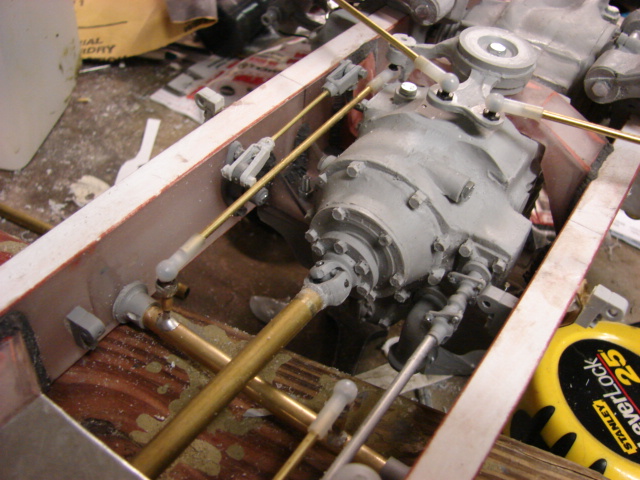

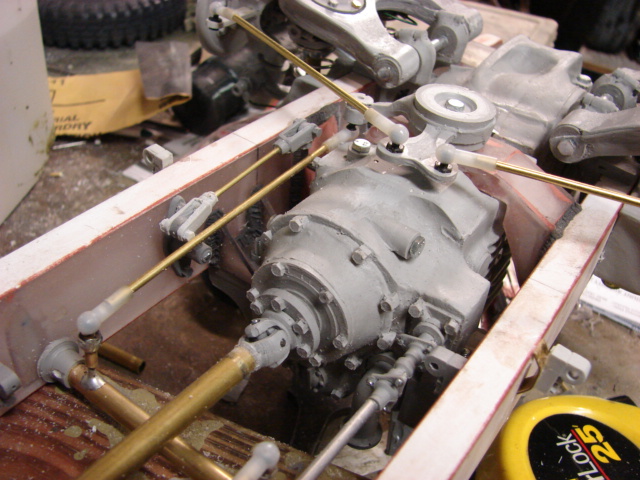

The transmission casing has been installed, and added to the catalog. http://www.eastcoastarmory.com/222.htm

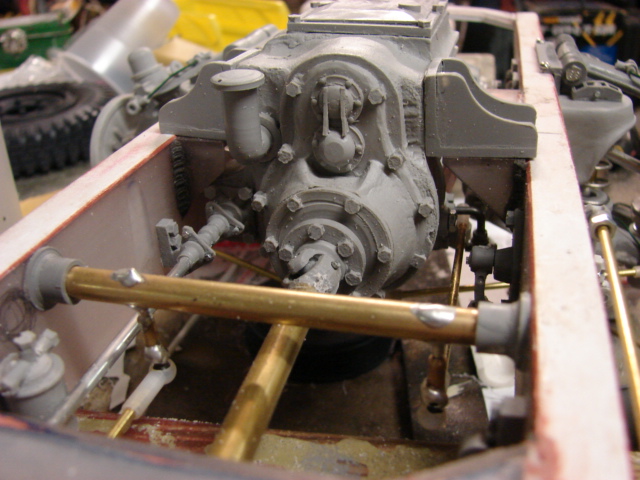

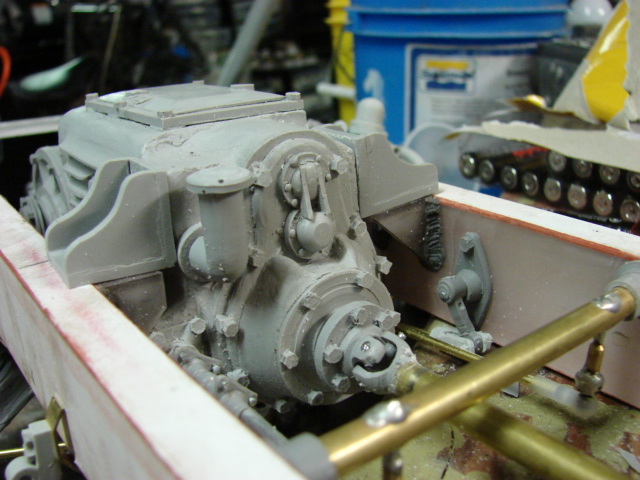

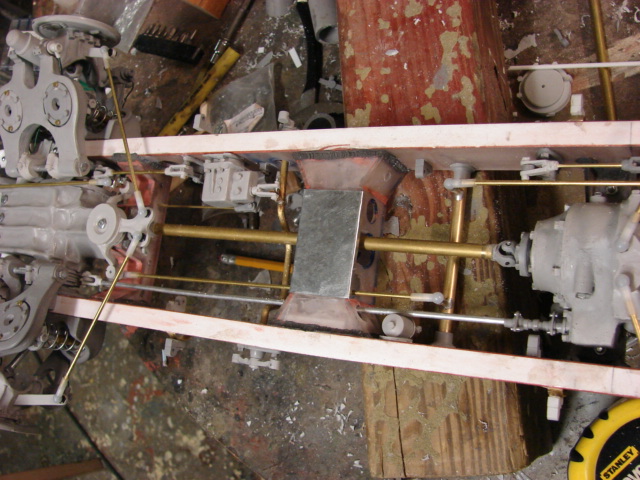

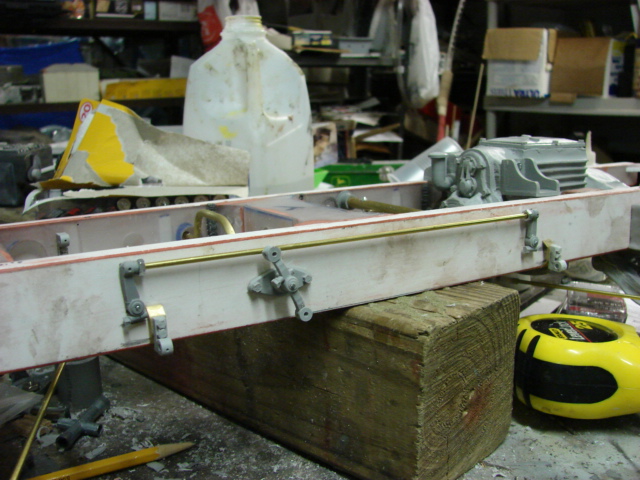

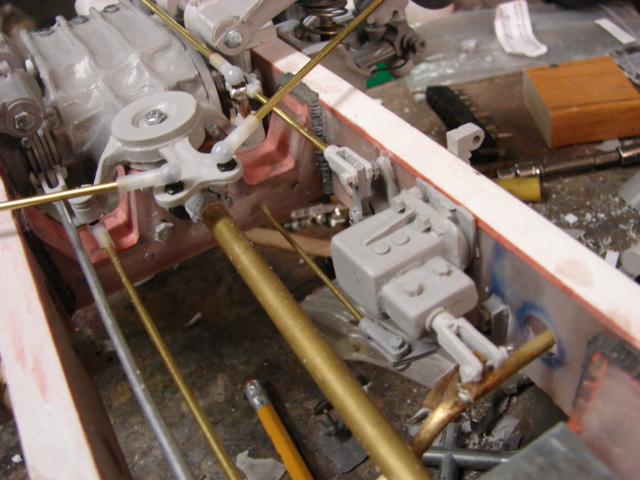

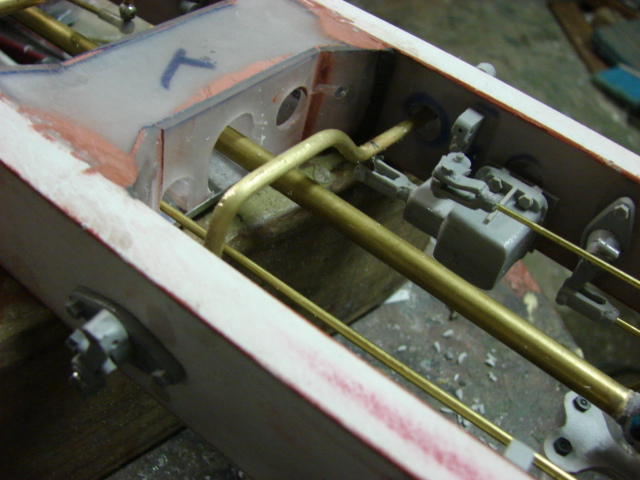

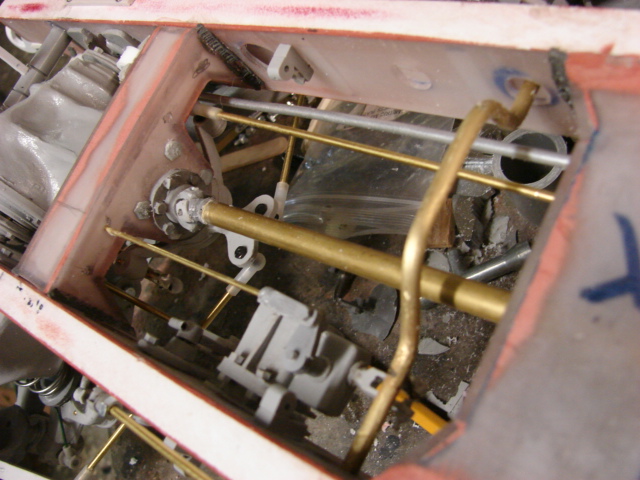

the transmission connects to the front differential via a long drive shaft that runs through the length if the chassis.

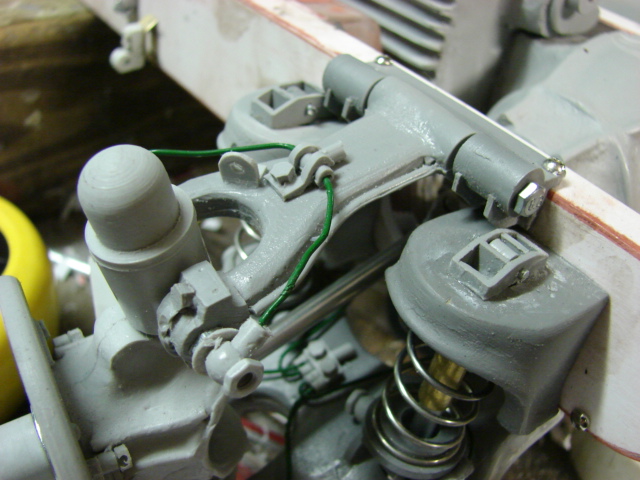

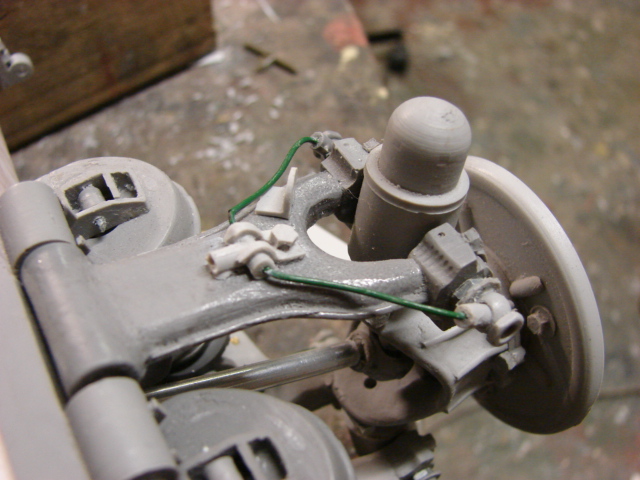

The smaller rod that runs along the the drive shaft is the shifter. This rod connects to the stick shift and is what allows you to change through the gears.

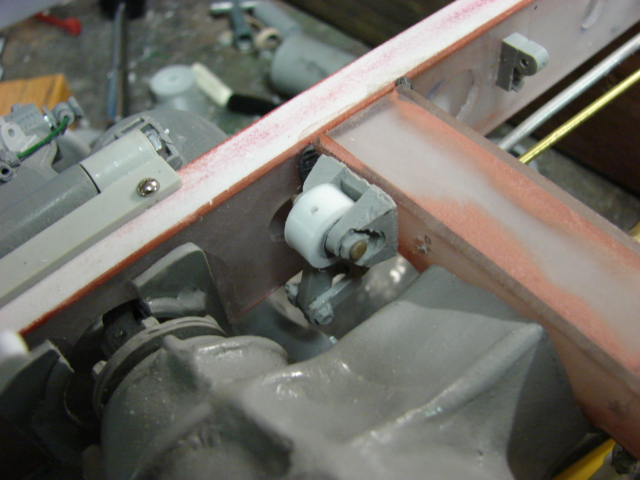

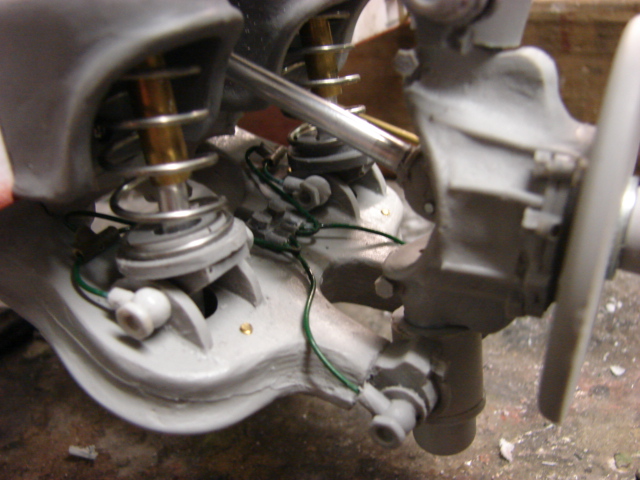

The armored car's breaking system was also partially added. The 222 had both a hand break and regular driving break. Once the chassis get's it's base coat the rest of the cables will be mounted. Because of all of the equipment on the interior of the chassis, the breaking system must run through the exterior of the chassis frame

The hand break is located in the transmission housing, and is controlled via a hand lever in the driver's station. The hand break connections are done via a solid connection.

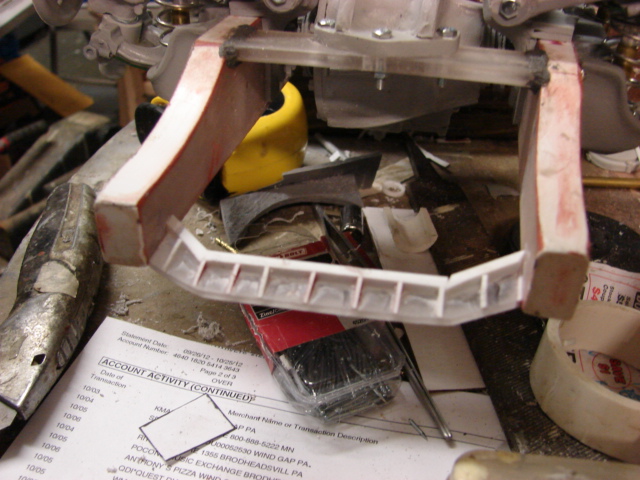

The break pedal, Accelerator, and the clutch are all mounted together on a bar. This bar is located below the floor boards.

All of the pedals, stick shift, and hand break lever will be added after the installation of the floor boards.

For the breaking system the pedal is connected to a hydraulic box which in turn is connected to a horizontal bar. This horizontal bar is connected to the pulley cable system...which is then connects to the wheels.

Another hydraulic system that the 222 had and was mounted was the lubrication system. The 222's suspension has many lube points and rather than having a zerk fitting for all of these points the 222 had plumbing lines that connected to all of these locations. This way all of the joints would the needed lubrication.

All of these lines would Y off to their needed locations.

For the bottom set of swing arms the plumbing would diverge into 4 channels. The two would go to the pivot points on the bottom swing arm, while the other two would separate again and would connect to the spring level shelf. Both shelves received these lines.

The oil reservoir is found behind the main bulkhead

On the lower chassis main bulkhead I added a steel plate which is found on the real vehicle. The plate covers the gap that is cut into the bulkhead for the driveshaft, and other connection rods. This plate prevents foreign objects from entering the space and causing problems.

On the front of the vehicle I mounted the front tow shackles

The tow hooks were the stock kits ones, and were reworked. The stock kit hexagonal appearance was smoothed out via a dremel. After the shape was rounded off I heated the hooks with a heat gun, and bent the hooks to shape.

Once the hooks were bent they were bolted to the chassis.

The rear frame bulk head / engine mount was added. The bulkhead is all fabricated out of lexan, and styrene

Like the break lines I will be adding the control lines and the rest of the lube plumbing after the chassis is painted.

The break lines and the lube lines set will also be added to the catalog once the lines are completed.

A youtube video was created showing the progress

http://youtu.be/96fZa3cDURY

More pics were posted to the ECA facebook page

http://www.facebook.com/EastCoastArmory

I will now be assembling the upper hull. Once the upper hull is assembled I can then focus on the interior and engine detailing. More to come!