Hi folks,

long time since my last post but i did some work in the background. Now I'm at a point to think about how to realize specific parts. In my last post I mentioned the option for a group built. Now I would like to request more specifically.

Are some of you interessted in a group built?

How I think about this:

Some parts can be created easier using modern technologies like 3d printing or cnc milling or machining. But this will cost more money. The more people pay for one specific part the cheaper the part will be. Additionally the parts will have more details and you don't have to assemble more complex parts from many little parts.

I've been working on the drive wheel since a couple of weeks. 2 photos to show how it looks on the real thing:

(early version of the drive wheel cover - which I intend to realise)

(detail view but with a later version of the cover)

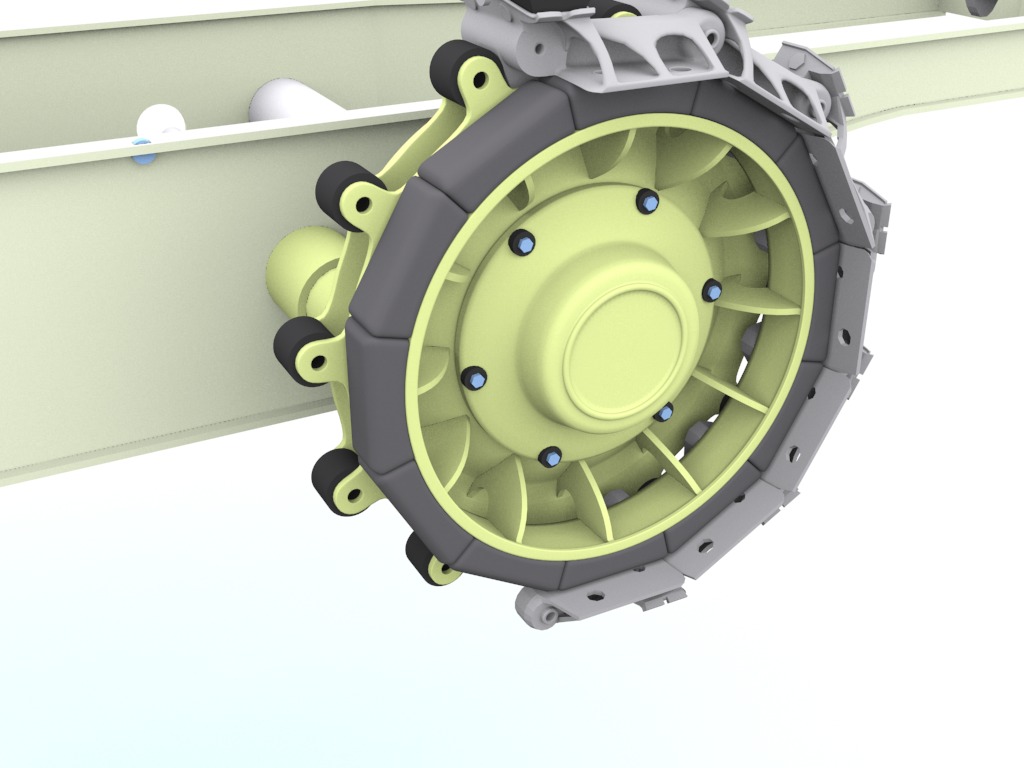

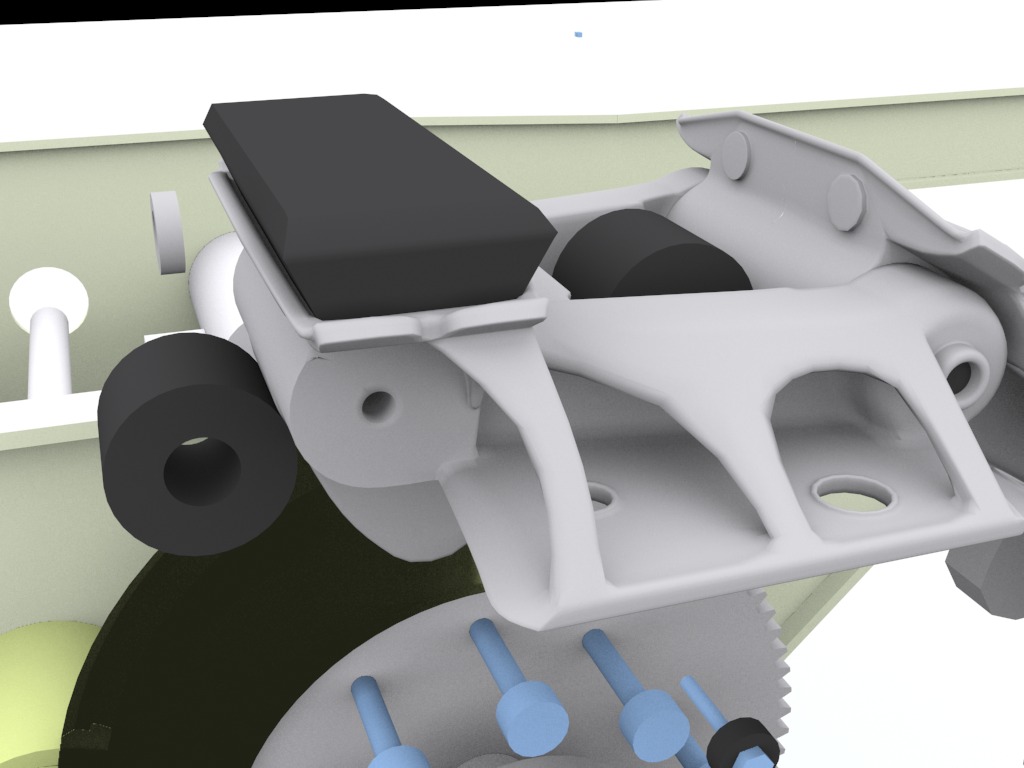

This is how my 3d model looks at the moment.

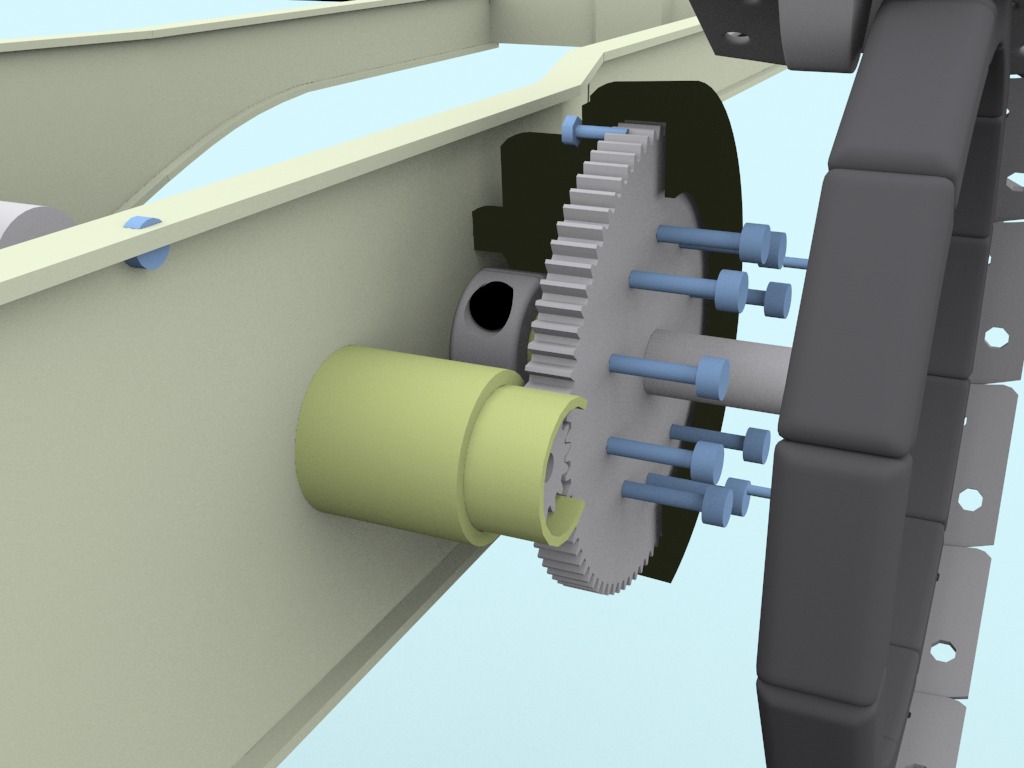

(the wheels is mounted on a spur gear wich runs via ball bearings on a fixed axle)

With this example part I would like to show the difference between the differnt ways for creation.

One way ist to assemble the drive wheel of a machined (lathe) brass base part and some cnc made parts from brass sheet. Theese parts have to be soldered together wich could be a very frustrating job. Following pic shows thees parts.

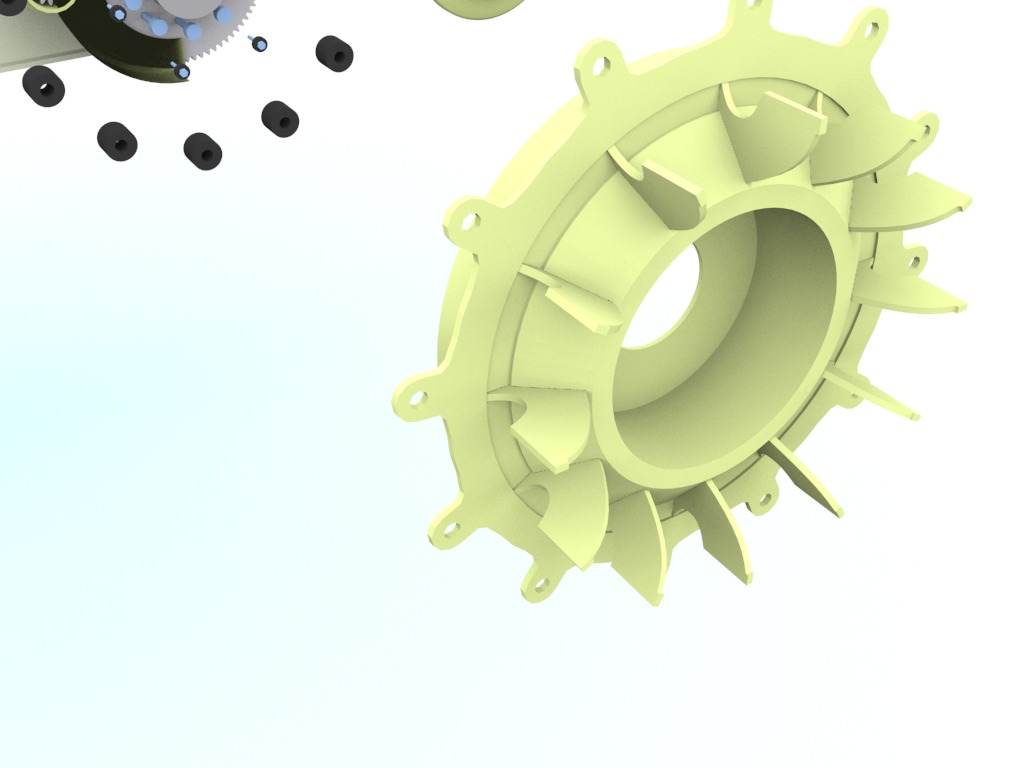

For the other way we need a 3d modell which has to be 3d printed (shapeways for example) to get a prototype. This is needed by a casting company to create a die. This way one could bring all details to the model (like embossing details on the surface).

Here you can see how this casted part could look like (without surface details):

Costs for this way :

1. 3d printing depending on the material and size

2. Creating the die (about 80 -100 EUR) depending on the complexity.

3. Cost per casted part.

This way I intend to create the track links because I need about 80 pieces for one Famo.

This rendering shows the 3d track link in an almost finished version.

Some more information about how I intend to make the model from the todays point of view:

The frame: made of cnc cutted brass sheets (1,2 mm) and brass pipes soldered together

Rubber parts (front tires, track pads, rings on the wheels) made from cold vulcanising rubber material. (dies are needed).

Motor and gear box : I think, my version with the steering gear is too experimental and a classic concept with 2 motors should be used.

The running wheels : there are 3 different version on one Famo. I intent theese wheels to be castet in brass.

The rims of the front wheels: like the original I would like to create the 3 parts of the rim and the hub as seperated parts (castet in brass)

The car body: made of brass or bronce sheets using different techniques like:

for the fenders pressing metal sheets.

for other parts techniques inspired by Gerald Wingrove. Here are some details.

Before I write too much please let me know what you think. This should be a base to discuss the possibilities.

Bye

Matt