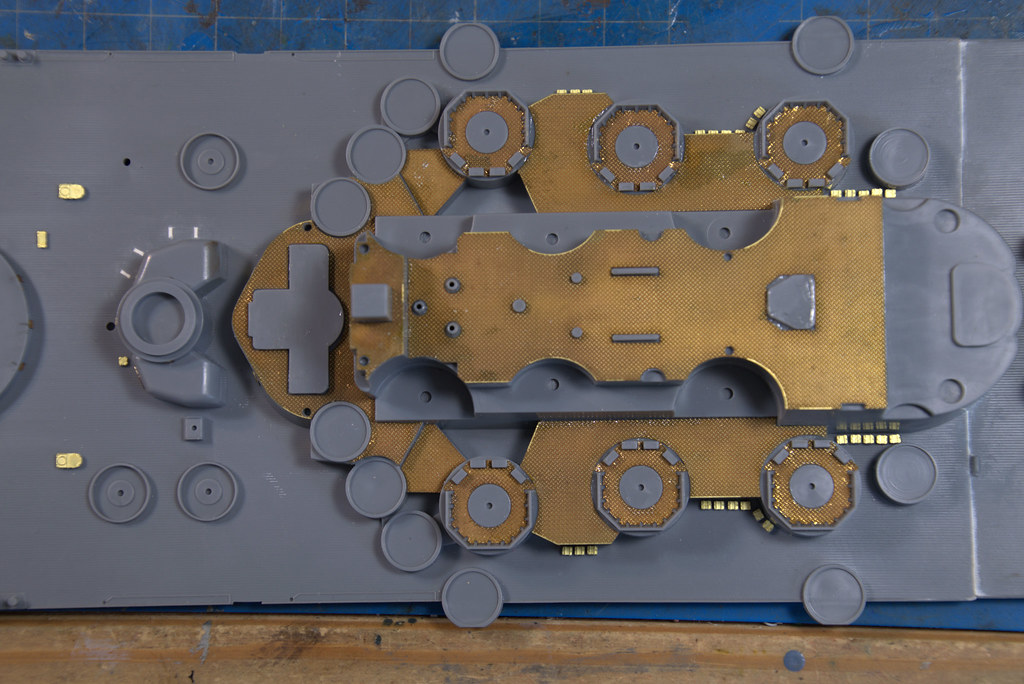

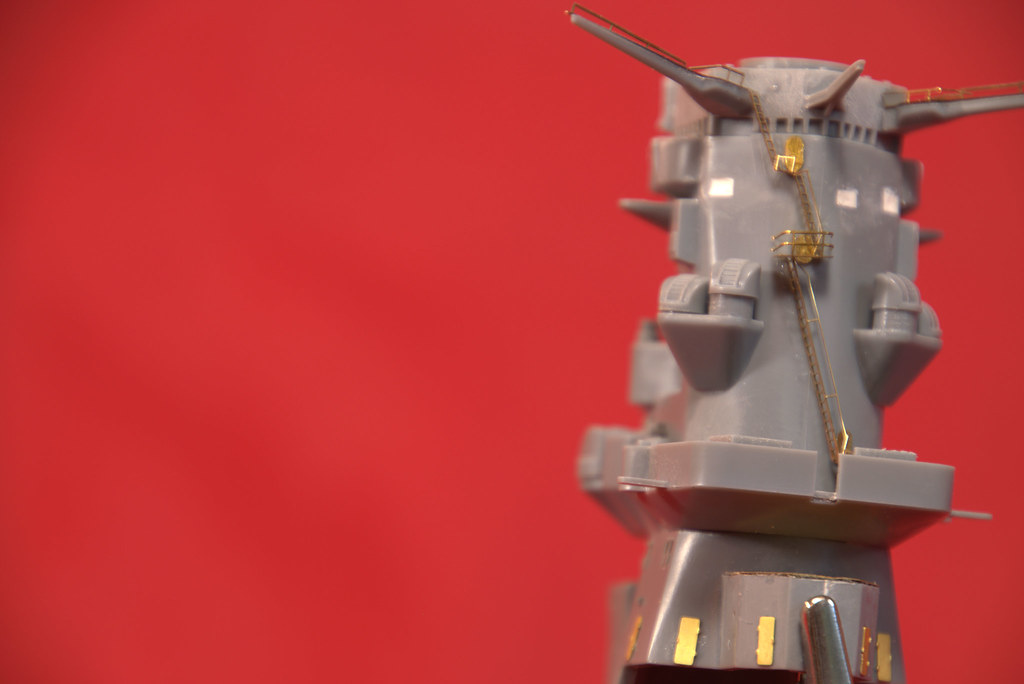

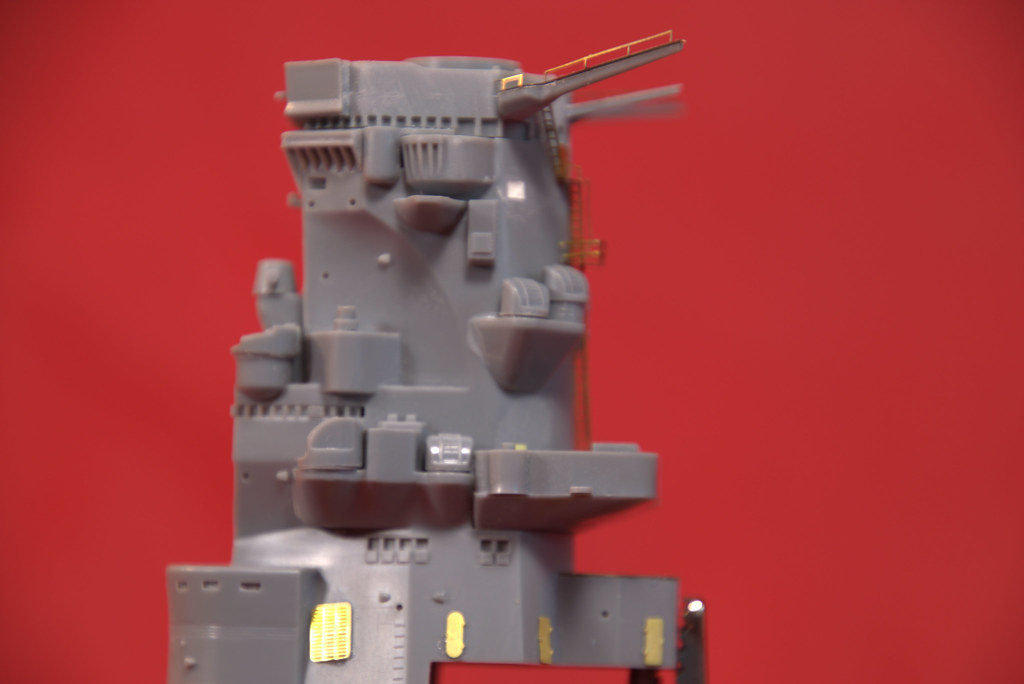

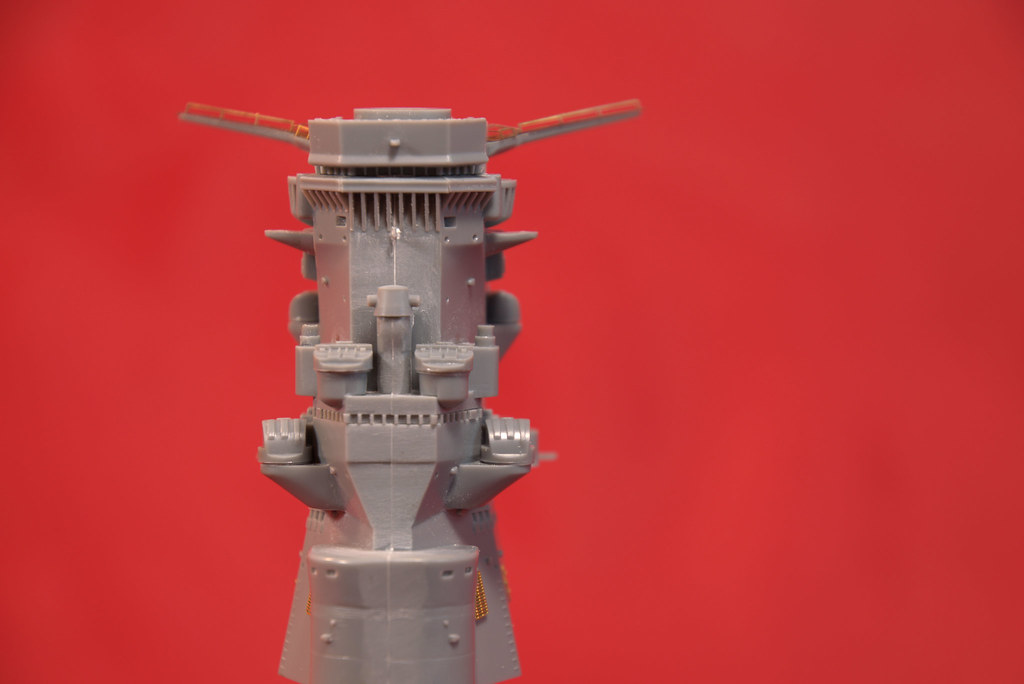

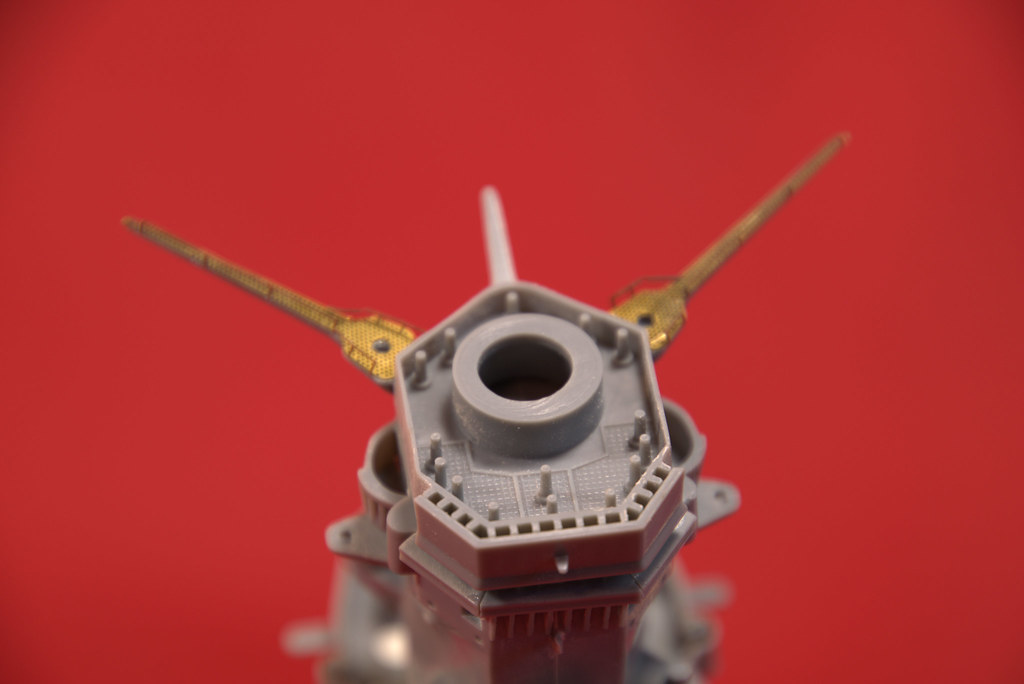

Thought I would post a few progress photos. Most of the time has been spent on installing PE on the deck and superstructure,

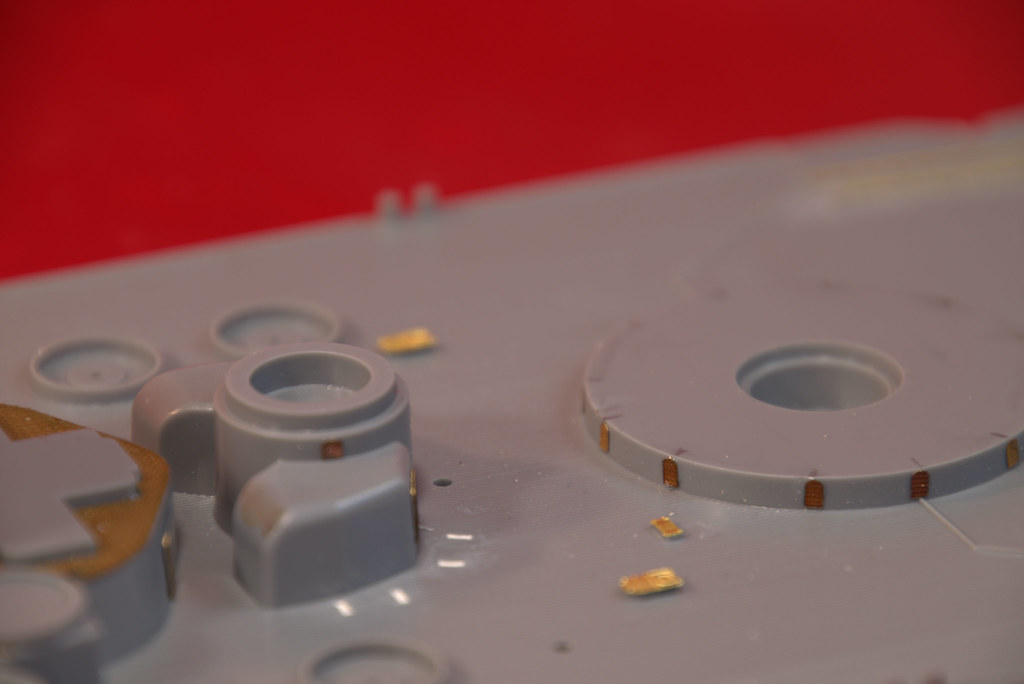

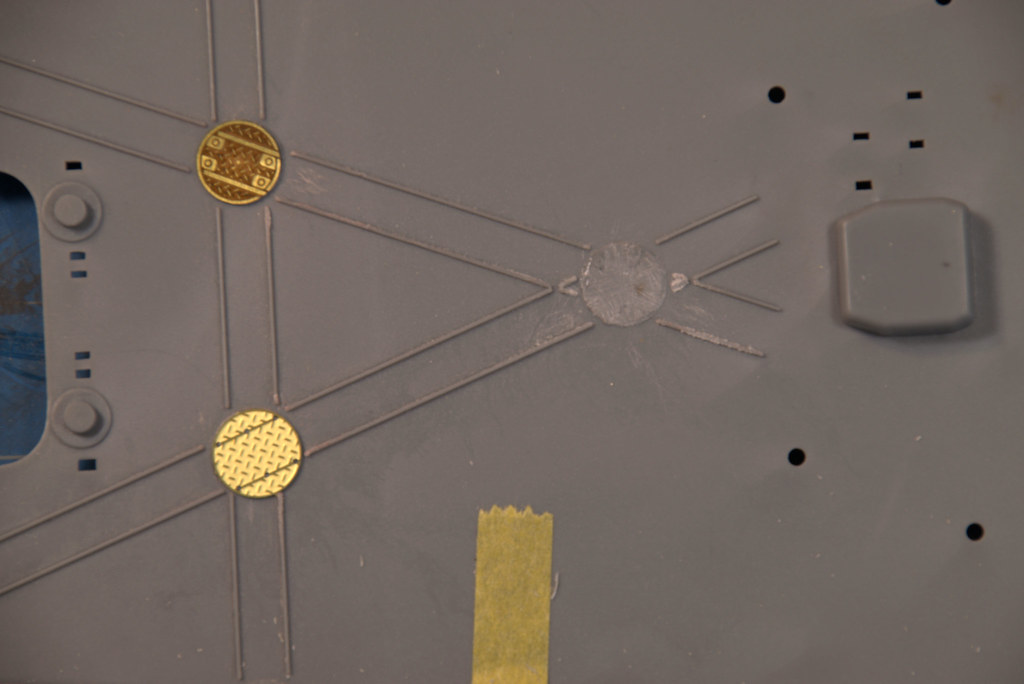

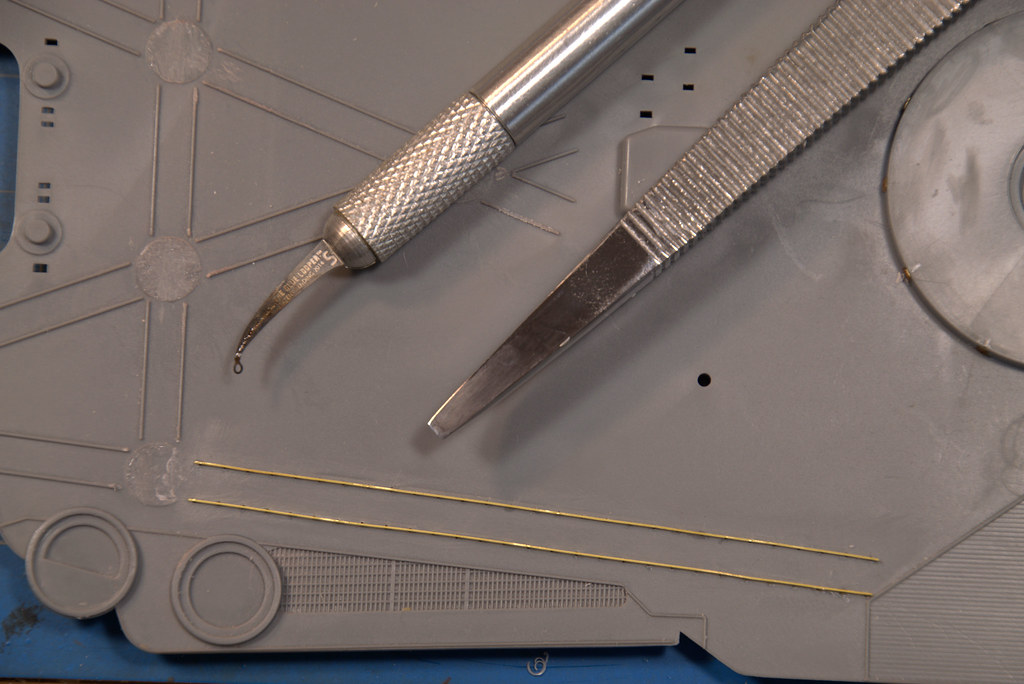

The PE being installed is a combo from Eduards and GMM. In this photo is a comparison between the Eduards and GMM aircraft trolley turntable. The GMM is slightly larger and the rails align closer to the trolley rails than the Eduards.

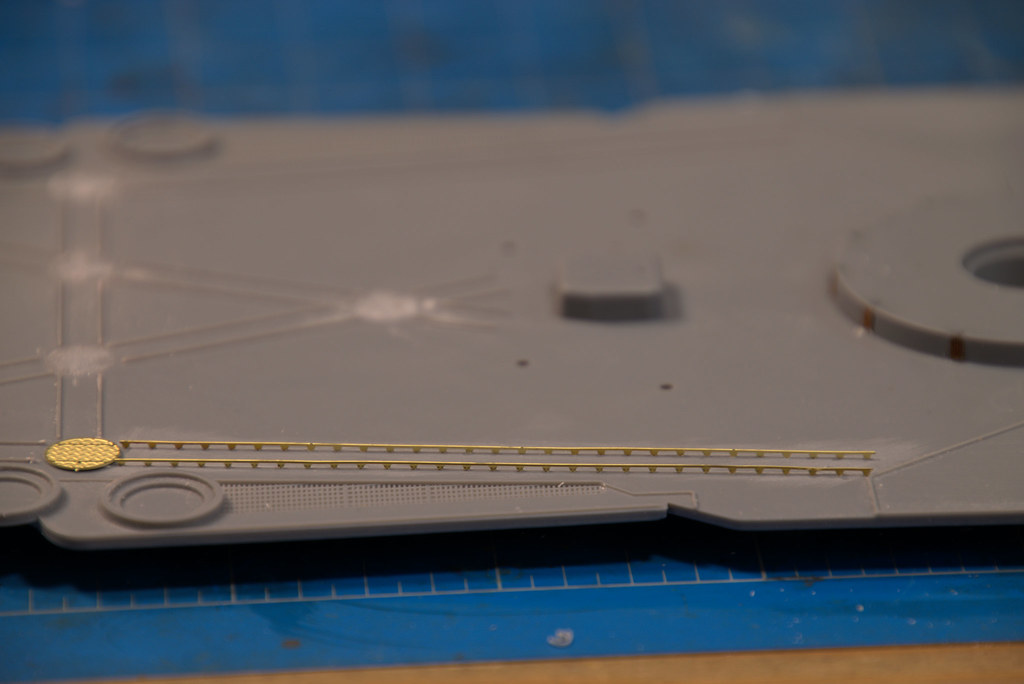

I decided to go with the GMM turntable. GMM also comes with replacement rails. GMM provides a gig to drill holes to set the replacement rails in place and keep them straight.

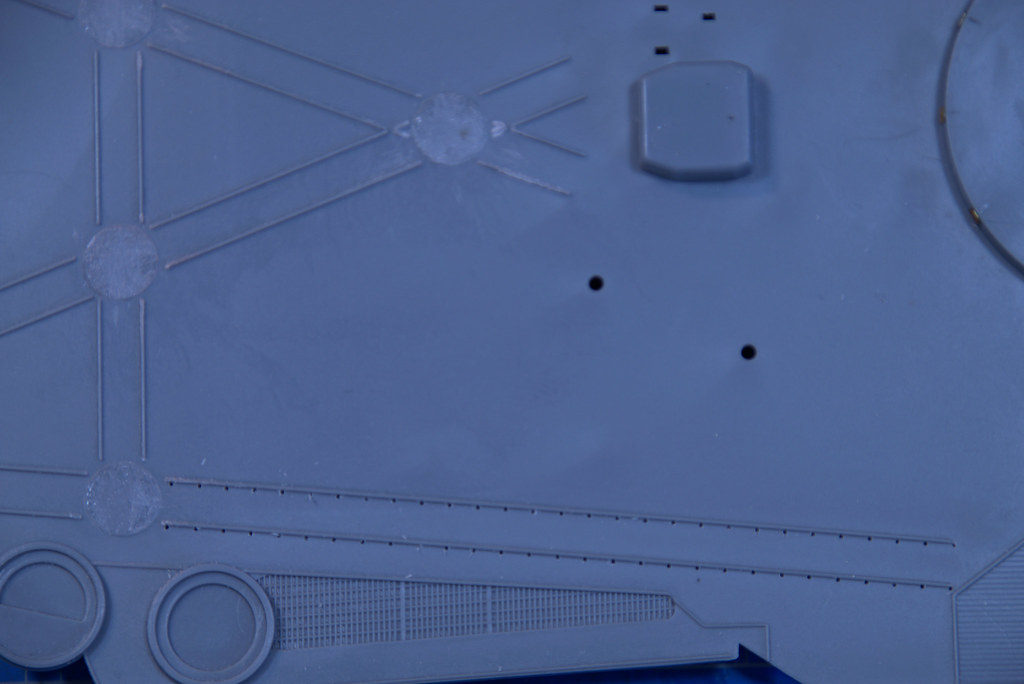

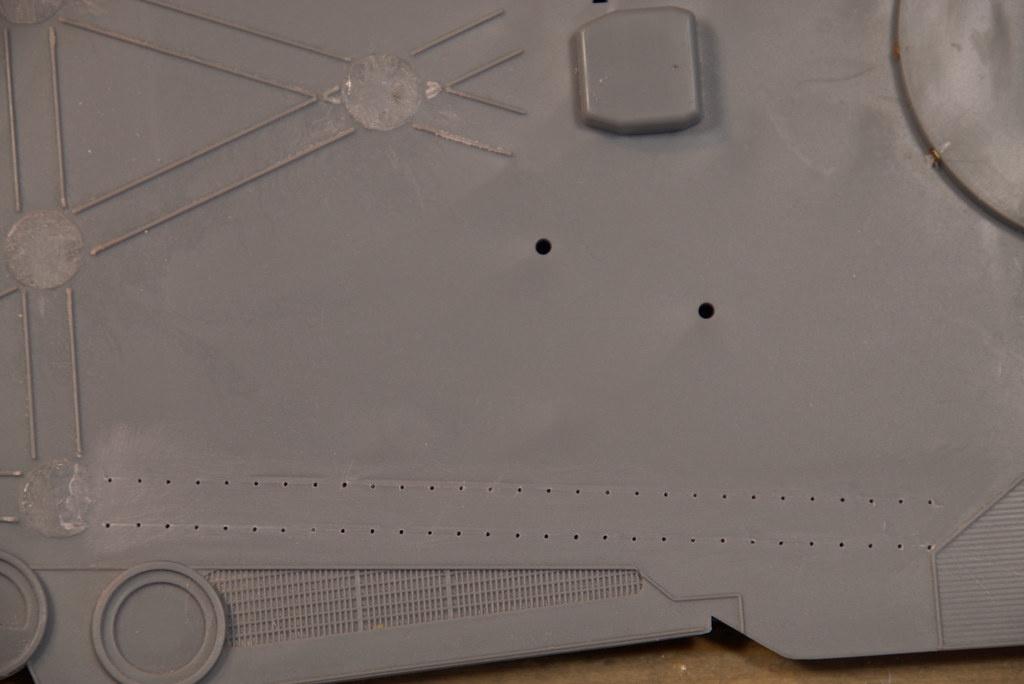

Then you have to remove the old molded on rails.

Install the new rails.

The glue looper and extra thin CA glue really made the job of gluing the rails in place a lot easier than I thought it would go. This would have been a bear using a pin or toothpick. The scraper I purchased from Micro Mark last month really made this a breeze to remove the old rails.

Also managed to get the lower hull painted using Tamiya hull red paint from the can 'TS-33'.

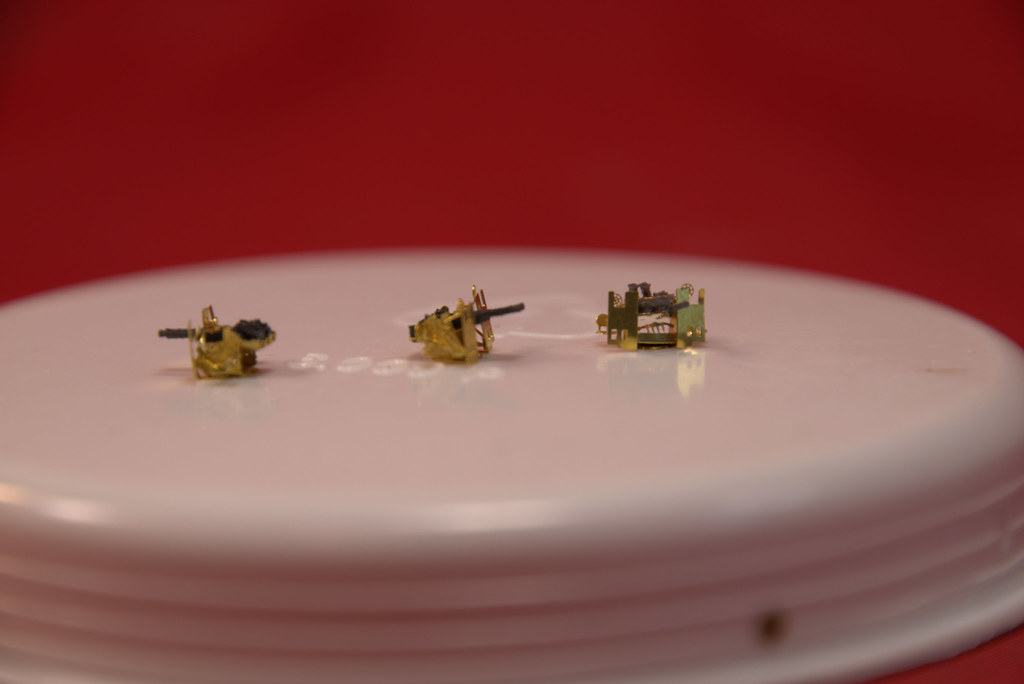

Build three of the triple 25mm MG mounts from 'Advance' just to see how much effort it was going to take. My first one took me an hour the next 30 minutes and the third around 20 minutes. I not use to working with such tiny PE so the fits aren't perfect but should pass once painted and installed. I also have the 25mm MG from Voyager but they are complicated and beyond my skills (really my patience) so I will be sticking with Advance. Hopefully after the first ten they will be easier to assemble.

I do have a decision to make about the lookout deck above the bridge. The kit only comes with the stands for the binoculars but no binoculars. I have aftermarket resin binoculars for IJN ships that would work but they are already on stands. My dilemma is should I remove the stands from the kit and replacement them with aftermarket binoculars or remove the binoculars from their stands and glue them to the existing stands. My concern is I may make a mess of the deck removing the existing stands but the stands seem out of scale to the resin ones. What to do?

Still have a lot more PE to install on the deck and superstrutures not counting having to remove all of the molded trolley rails and install the new one. Making progress slowly but surely.

Tomorrow is another day.

Marcus