Carving an 18th century ship's launch at 1/8th scale.

INTRODUCTION

Since ancient times, larger ships often carried one or more small boats as auxilary craft. These boats were towed behind the mother ship. Later, this auxilary craft was stowed on the main deck. By the 18th century, the ship's launch was the main auxilary boat stowed over the main hatch with other lesser boats such as a pinnace, a cutter and a smaller dinghy nested on top. On larger man-of wars, all boats were rested on skids side-by-side on the main deck. The purpose of the launch was not onlty to transport officers from ship to ship, but also to shore. The launch also served as a transport for supplies, or carry multipal personnel to unload on beaches. On sailing ship kits, of either wood or plastic, auxilary craft are included in the kit. For scratch builders, making a launch is a necessity if authenticity is to be required.

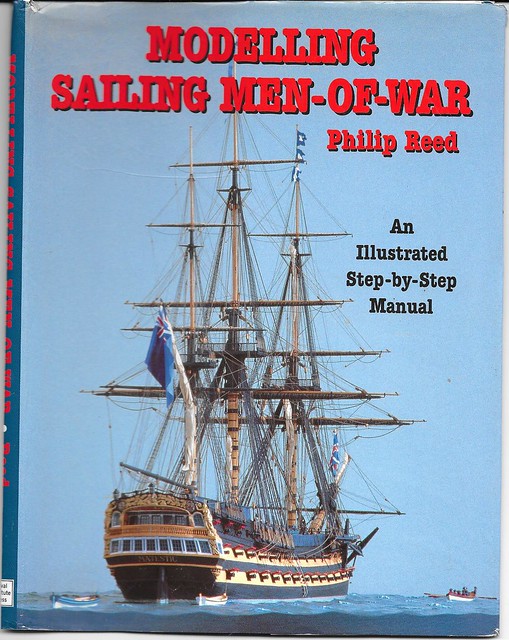

The inspiration for the lanch carving project came from the book,"Modeling Sailing Men-of War", by the expert modeler, Philip Reed. This publication is a step-by-step guide for the construction of the 74 gun line of battle ship, HMS MAJESTIC. All steps of construction is enployed by a series of photographs with accompanying written texts of instruction. Based on the design of HMS CANADA, by William Batley, MAJESTIC was commissioned in 1790 and served in most of the major sea battle duing the Napoleonic conflicts of the late 18th century and early 19th century wars with France. Reduced to a 32 gun frigate in 1812, MAJECTIC helped capture the USS PRESIDENT in 1815. After 26 years of service, MAJESTIC was broken up in 1816.

On page 83 of "Modeling Sailing Men-of-War", the author begins a series of photo-texts on how to construct a ship's launch by making molds of the launch with ABS plastic. Rather than follow this route, I"ve decided to carve a launch from scrap pine by using a Dremel 7300 battery powered cordless drill with a table saw, gauging berrs on the drill and final sanding with an Electro-File hand sander. Returning back to the book to complete the fitting out of the model launch.

The first step of launch carving was the selection of a piece of scrap pine. With an architectural scale ruler, 1/8th scale was decided for a 34 foot launch for a French frigate that has been put on the back burner for later work. A cardboard template of the launch profile was cut with scissors and traced on the scrap wood. Parallel pencil lines were drawn on the scrap wood to indicate the first cut on a table saw. The stern part was also penciled in.

This is the rough cut of the model launch after the table saw removed the outer scrap pieces.

Sanding for a rough outline of the launch. The parellel lines on the top of the launch-to-be is where a grove is to be cut to receive the keel.

Here are the essential tools to begin shaping the launch. The box cutter knife was used to shape the general outline of the launch. Then, the Dremel battery powered cordless drill began to hollow out the interier of the launch and the outer profile. The bigger burrs employed on the drill for rough gouging, while the smaller burrs for closer detail. Sanding heads when required.

Finally, the launch is in the first stage of creation after much hollowing out the enterior of the project.

Here is the progress so far by gauging and sanding. At this point, caution is required in this shaping process so that the walls of the launch is not over cut and ruined. To insure that gauging and sanding did not go to far, the launch was held close to a naked illuminated light bulb. If light shown through the wood, then it was time to stop gauging and sanding. The tweezers give an example of size and scale of the launch project.

Final sanding begins. The Electro-File sander does the job quite well, to eliminate the repetative motion of sanding by hand. The small sanding stick is for hard to reach places where the Electro-Fil can not reach. This tool has an oscillating motion to sand a sanding stick that has sand paper attached. The oscillating movement is much like a turkey carver that is used to cut slices of the Thanksgiving bird. A grove has been cut on the underside of the launch to receive the future keel.

Here is the finished product after sanding with the Electro-File beside an architectural ruler, which shows a 34 foot launch at 1/8th scale. The next process will be the application of thin width computer paper strips on the outside of the hull to simulate clinker planking from the keel to the gunwale.

To be continued Happy modeling Crackers