I'm usually on the darkside, building armor, but the quirkiness of this aircraft was just callin' out to me. So long story short, I decided to start building it on a whim and now it's also an entry in the Prototype GB All Era's. The official name of this primitive aircraft or the Venetian blind looking-thing, is the Horatio Phillips Steam-Powered Multiplane. Now you may be thinking who the heck is Horatio or what is a multiplane, so to better explain here's a quick history lesson.

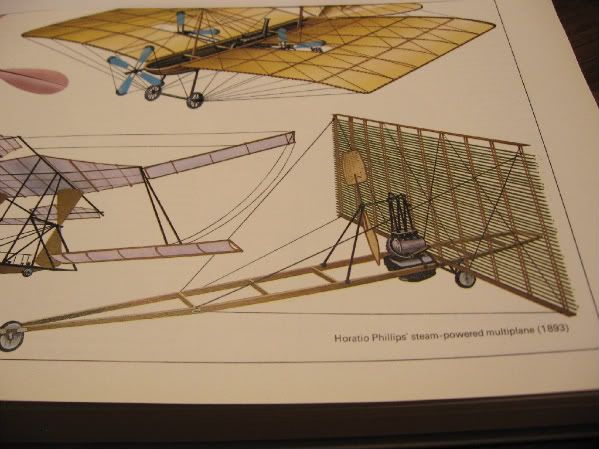

The Horatio Phillips Steam-Powered Multiplane was built in 1893, by who else, Horatio Frederick Phillips. An early English avaiation pioneer, born in 1845 in Streatham, a suburb of London, England. He designed a craft in 1893 with 50 slats (hence the name "multiplane"). Presumably, he was hoping all those planes would produce lift in abundance. The wing frame measured 22 feet long and only 1.5 inches wide, the machine was powered by a coal-fired steam engine that turned the propeller at 400 revolutions per minute. He constructed this large device for testing the effective lift of what he termed "sustainers" or in other words airfoils. As a test/prototype vehicle, it was not designed to be manned, but was used to test lift capabilities. Phillips has long since been forgotten to history, but his development of curved surfaces helped advanced the early days of applied aerodynamics. Oh and and for those wondering how far this aircraft flew....it was able to lift its own weight plus 72 pounds (a total of 402 pounds) some three feet at a speed of about 40 mph.

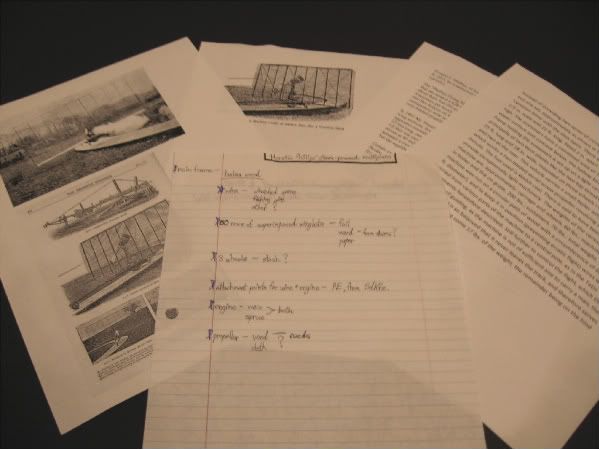

Okay, know that I explained that, I can get on with the thread and WIP. The pic above is one of the reference drawings I have and it best shows the aircraft out of all the pics I have. Which isn't many. For my main reference book I'm using The World Encyclopedia of Civil Aircraft by Enzo Angelucci, that's where the color drawing above came from. As for the rest of my info, it's off the web from random sites.

To help with the scratching, since it's my first ever scratch project, I created a little cheat sheet with the various main parts of the aircraft and what I plan to use for each part.

For the main frame I decided to use wood, pretty sure it's cedar. Not 100% sure, since I get alot of the wood from scraps from a nearby architectural wood molding place. How's that for being resourceful. The wood frame "planks" are cut to a size of 0.20 X 0.30 inches at 9.40 inches long(these numbers were scaled down from the original dimensions). However they are too straight and need a curve, so......I just today got around to putting them in the water to soak for a day, they need to be completley wet and soaked through so I can bend them to the correct curvature of the frame.

All comments, questions, and suggestions welcome!