Michael,

Thanks for the kind words. Yes gunmetal or aluminium mixed whith gunmetal would be much better if I can work up the enthusiasm for a rather tricky paint job.

On a different subject, I just had to post this.

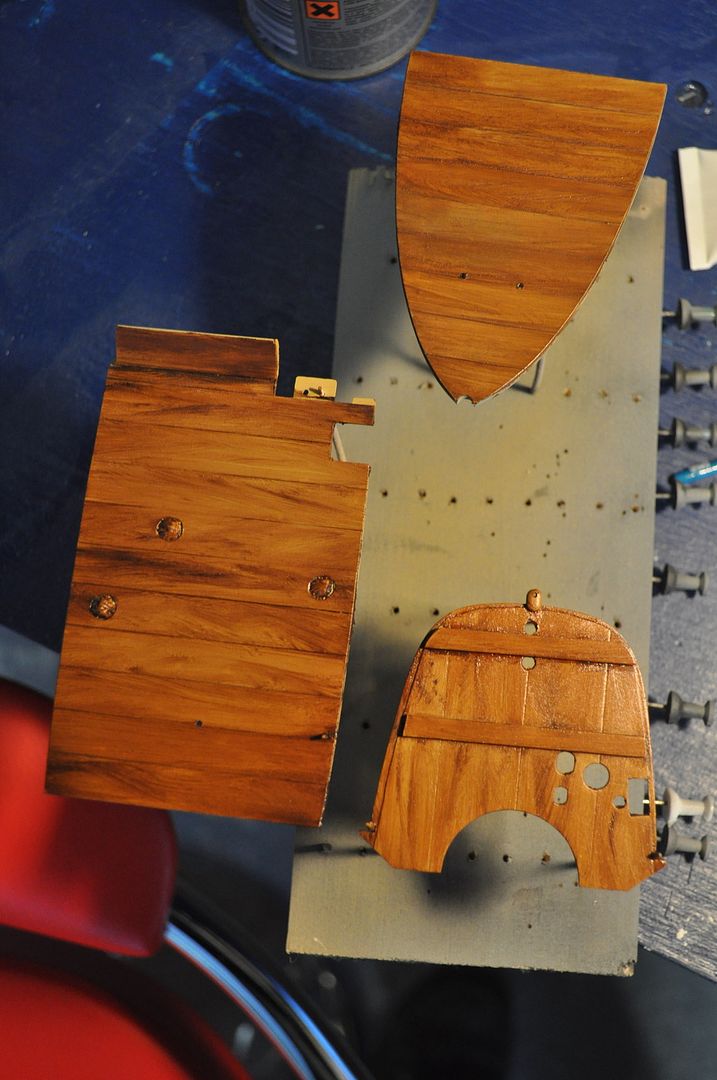

One of my original reasons for wanting to do this model was the wooden bits. Your use of veneer almost changed my mind. I thought it really effective, and very close to the colours you see in the photos. I wasn't sure I had the skill or courage to do the sort of paint effects I had seen but if you don't try you won't know. So today I took the plunge and had a go using the techniques described on this link:www.agapemodels.com/.../simulating-wood-grain.

Clearly the technique is pretty much idiot proof. I have seldom felt so pleased with myself doing modelling than with the results shown below - more typical of me is throwing half a bottle of liquid cement across my bench (yesterday's drama) - skill.

It worked very well, though the colour is more teak than pine but I'm not going to be that fussy. There's still a layer or two of varnish to add. Unfortunately it means I there is little more to do (just the other side of the front bulkhead and the two rails). Maybe a WW1 subject beckons or a completely unpainted Mosquito...

Before (just Halfords primer)...

After X59 Desert yellow and an assortment of Umbra and Sienna oils. Now just need to patiently wait for it to dry...