MASTING, RIGGING WITH SAILS of the HMS PELICAN.

Now that all the elements of the hull construction has been completed, it's time to begin masting, rigging and sail attachment of the model. Starting from the bow to work toward the stern of the model, the bowsprit is constructed with the Union Jack flag attached to its staff. Block pullies for the sprit sail is attached to the cap, painted black, as well, as the bee block for rigging when the sprit sail is in place. The bowsprit's heel is is placed in line with the foremast and supported by the stem, to situated its length exactly on the center line of the ship like all the other masts.

The sprit sail yard, painted back like most of the British ships of that period, is now ready to receive its sail, after the sail has been sewn with reef points, yard lashings, clew loops and cringles. The model sail is made from slikspan dyed with light brown acrylic paint diluted in water, then dried.

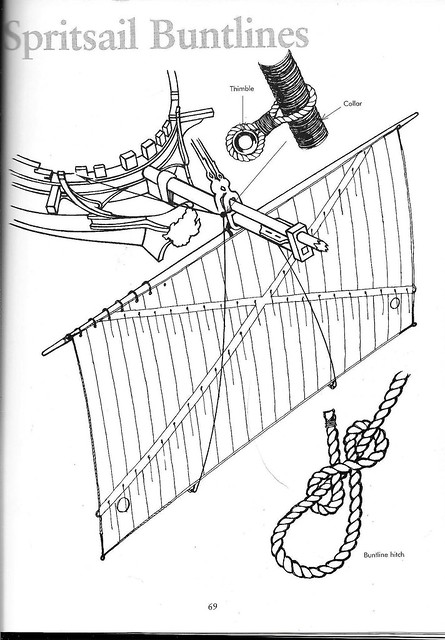

The main source of model rigging and masting has been "Rigging Period Ship Models" by Lennarth Petersson. This publication is a gold mine of drawings and diagrams which show how each separate item of both standing and running rigging is fitted to the masts, yards, and sails. On page 69, is an illustration of the sprit sail on the bowsprit. Making the "X" style of reef points as featured on this illustration, will be a challenge. Instead of this configuration, it would seem that the reef points would be arrayed in a horizontal manner to be bent to the sprit sail yard. Perhaps someone on the Forum could explain why the sprit sail reef points are as seen on this illustration.

Happy modeling Crackers