Regarding the base

Some of you may recall my post to this WIP about the base. I was struggling to find a suitable platform to build my diorama on. I am not a woodworker, so making one from scratch was out. I had to find something that I could use straight up, or that I could manipulate by using equipment that I already have. Using a shadow box seemed like a good idea but I could not find one near to the size that I wanted. I then looked at ordering a custom box, but the cost of ordering one was out of sight. Finally, I came to the realization that I will have to make one. This brings me to my solution...

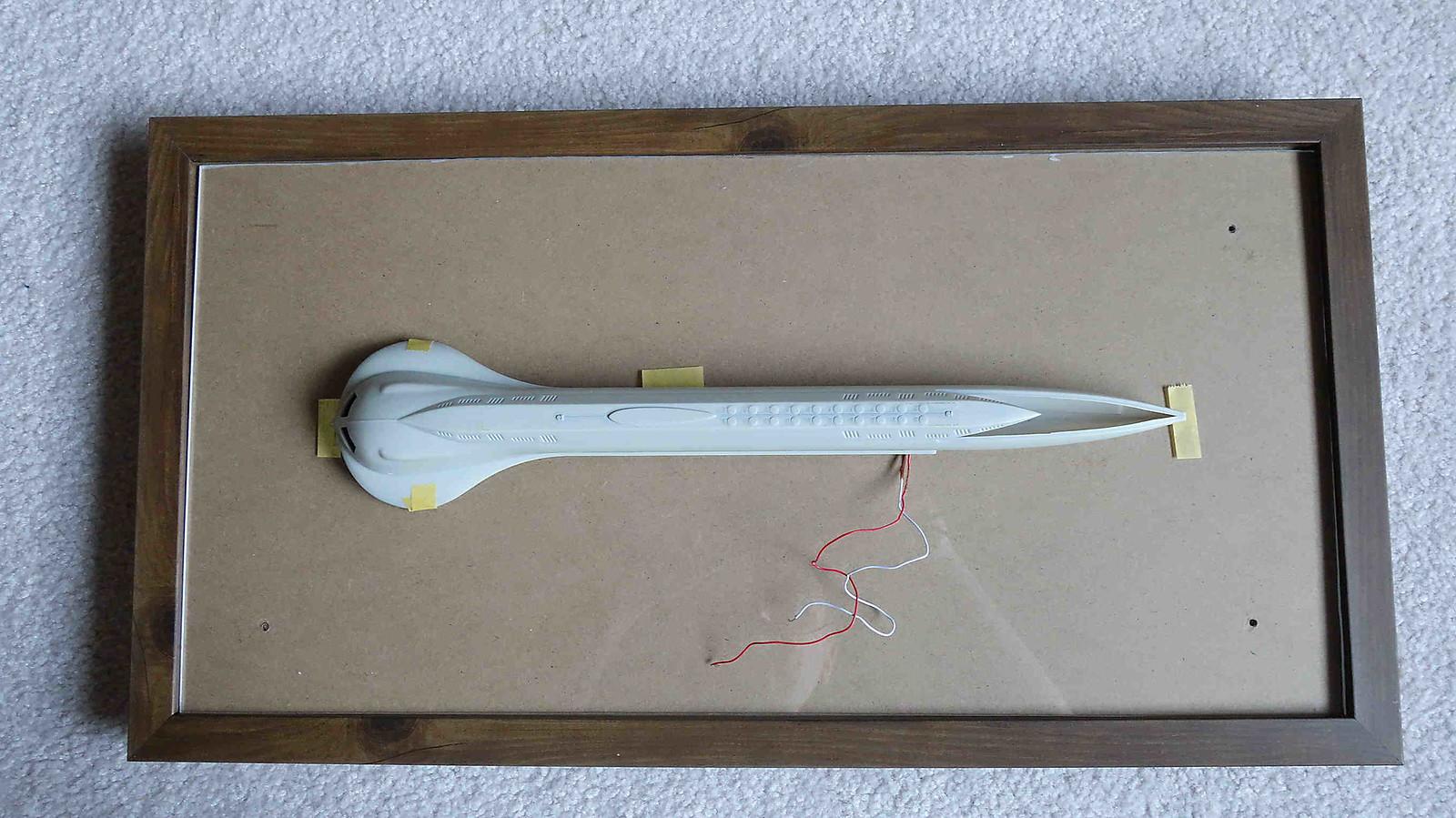

Below: Using a 40% off coupon I purchased this picture frame from Michaels for around $8. I laugh about the price when I consider the other options that I was looking at. This frame has the look and the dimensions that I want. The problem? It is far too shallow. The belly of the beast will hang too low. In fact, it will hang so low that it becomes its own stand. I have no choice but to do a serious Macgyver on this...

1. I will add feet to each corner. These will not only dress it up, but they will act as spacers, thusly raising the beast up off of the seafloor.

2. I will need to make a second sort of frame to enclose the bottom of the sub. This is not a functional requirement, but solely to pretty it up. It will be dang ugly underneath the base, and that won't do.

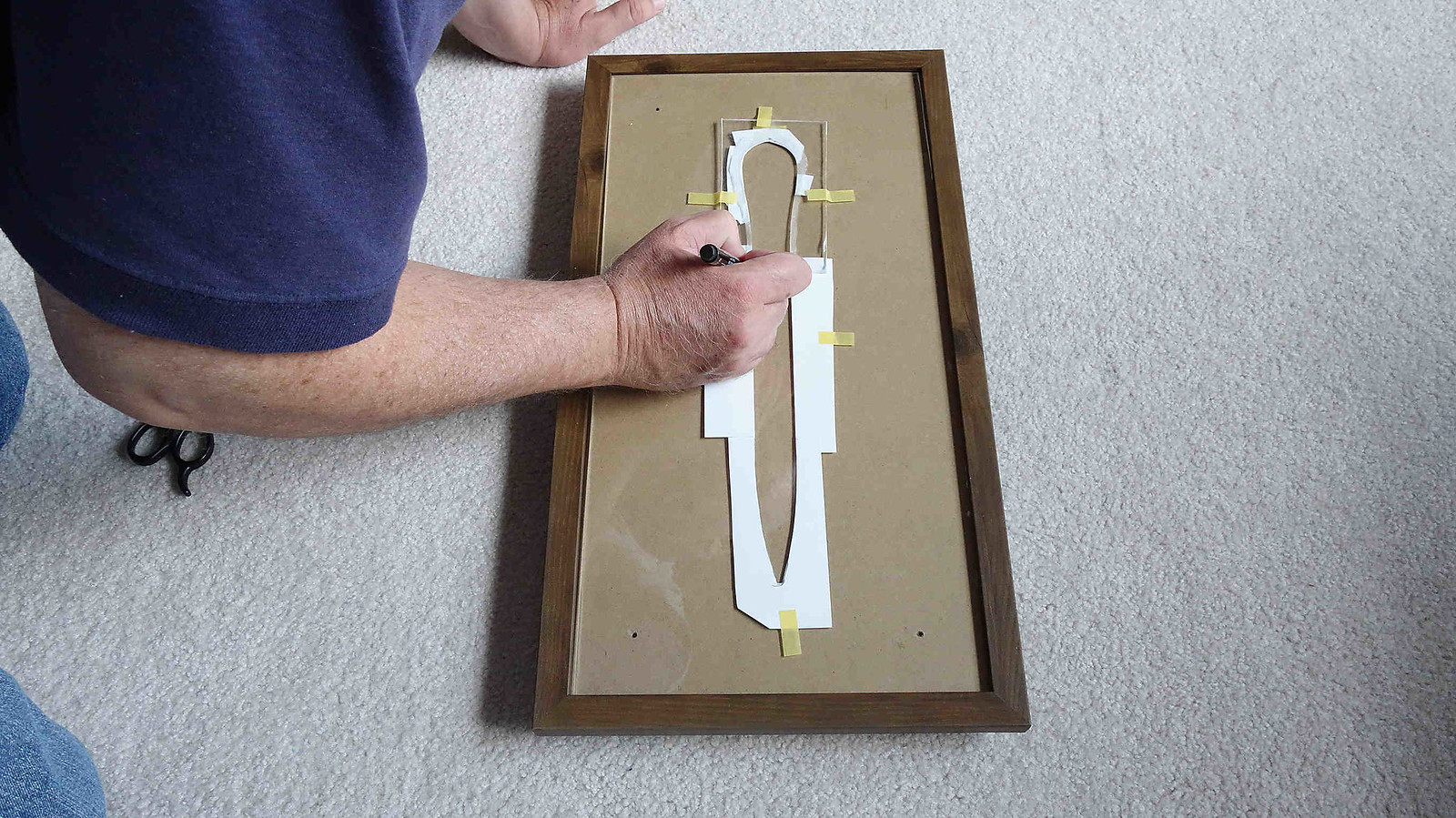

A side comment about this option. When I purchased this frame I had thought that it came with plexiglass. I thumped it a few times and it sure sounded like plastic. Um....WRONG! It is a nice big piece of glass. Drats... It's not a terrible problem, it's just more work. I already had some plexiglass, it just needed to be fitted. In truth, if the frame came as such, I would have had to trim theirs too. Theirs would have been less cutting though.

The reason for the cutting is that I am positioning the plexiglass piece above both the backboard and the lip that the glass and backboard sit under. I want the waterline higher up in relation to the frame. There will be more on this once when I start making the waves. So...the plexiglass had to fit within the frame, not under it, hence the cutting.

Finding its berth

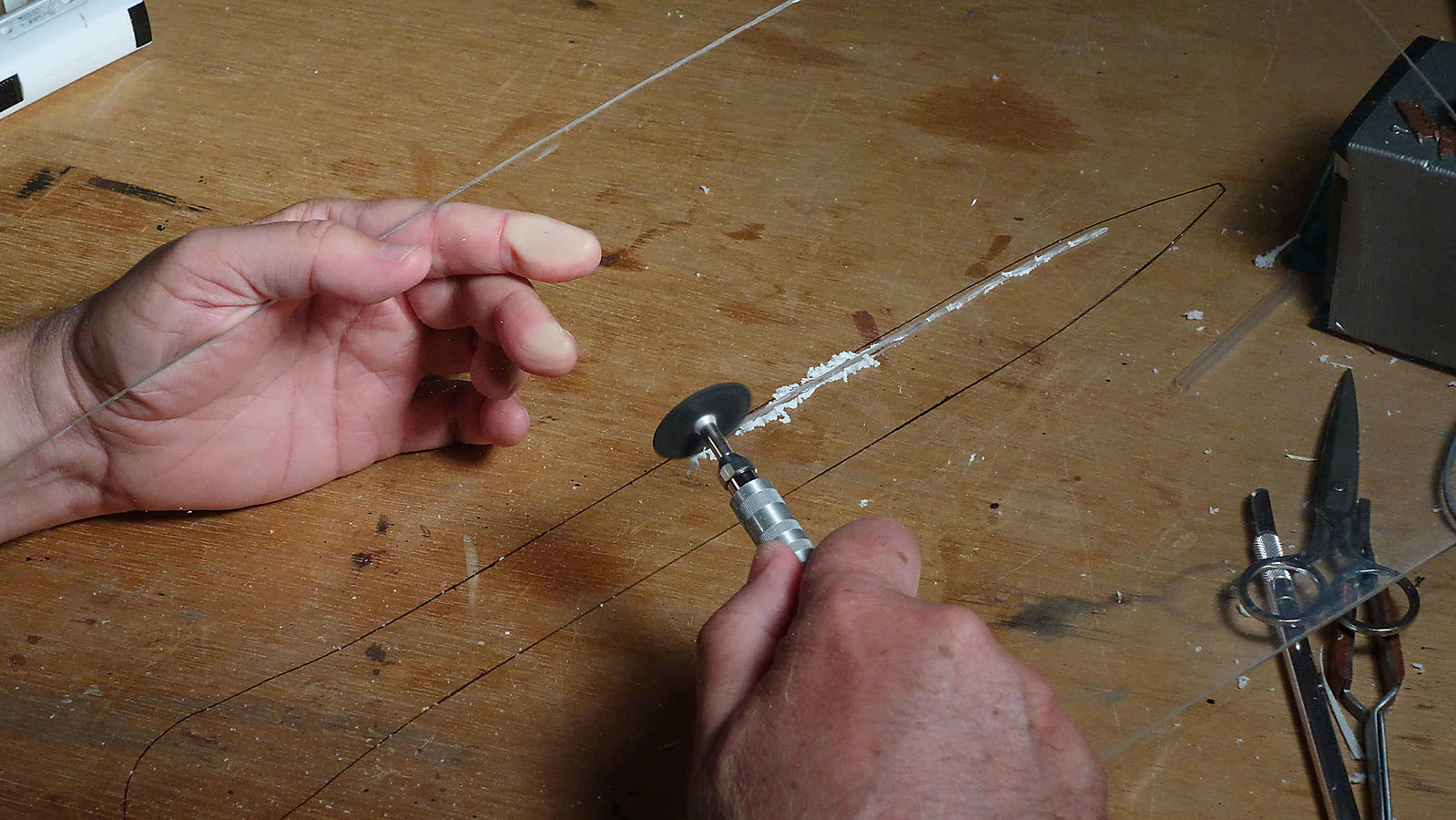

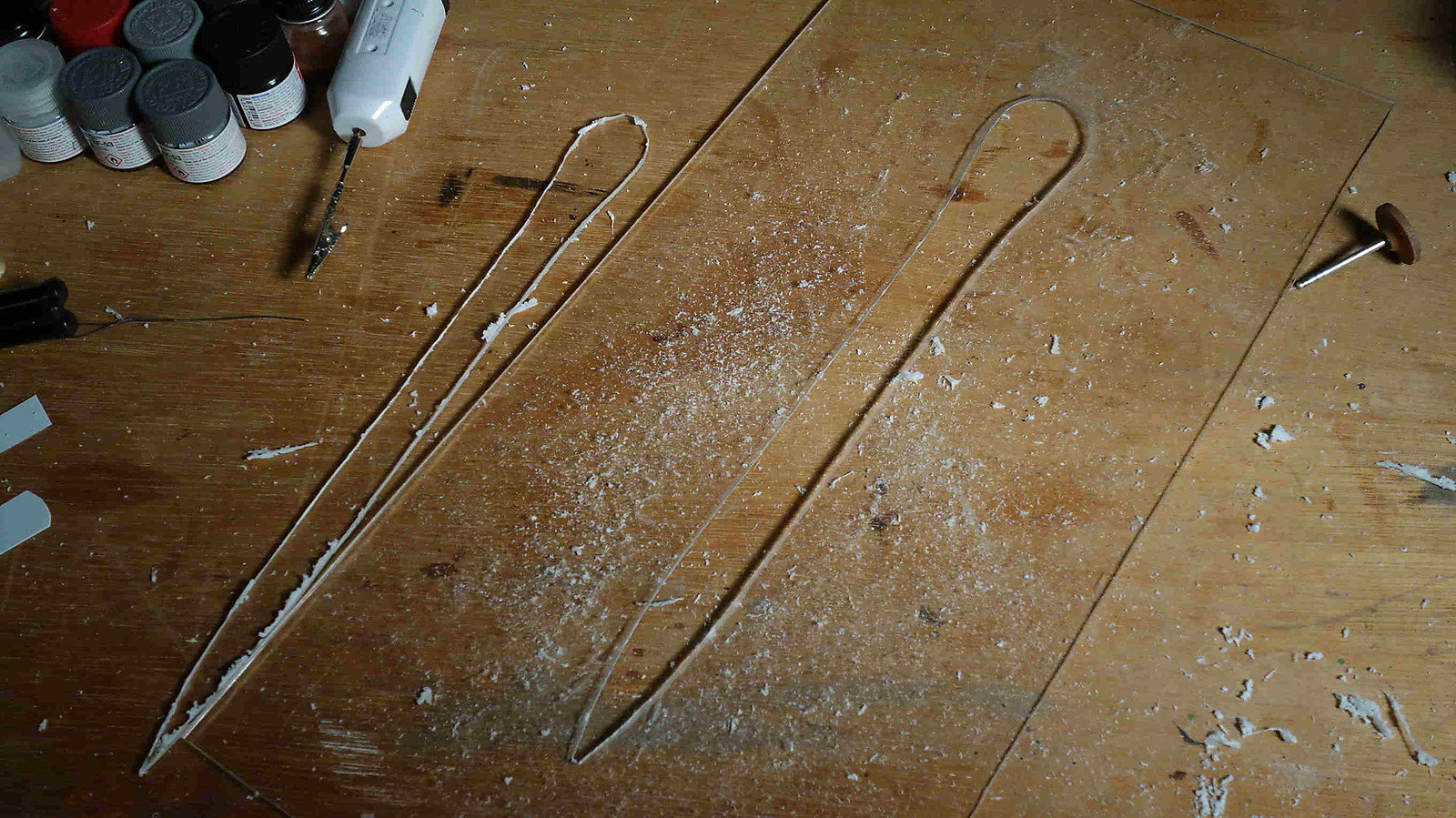

Notice the melted plastic as I cut. It occurred to me that this might be another way to make foamy water. It's just a thought.

That cutout would make one killer shank.

Overall, I am pleased with the fit. The extra work that I did on the template paid off. Phew...

Why the scuffing? To get a tight fit I had to shape the leading edges so that the plexiglass positions flat on the hull, and not only on one edge of the sheet. To bring back some clarity to the section at the bow it will be sanded and polished.

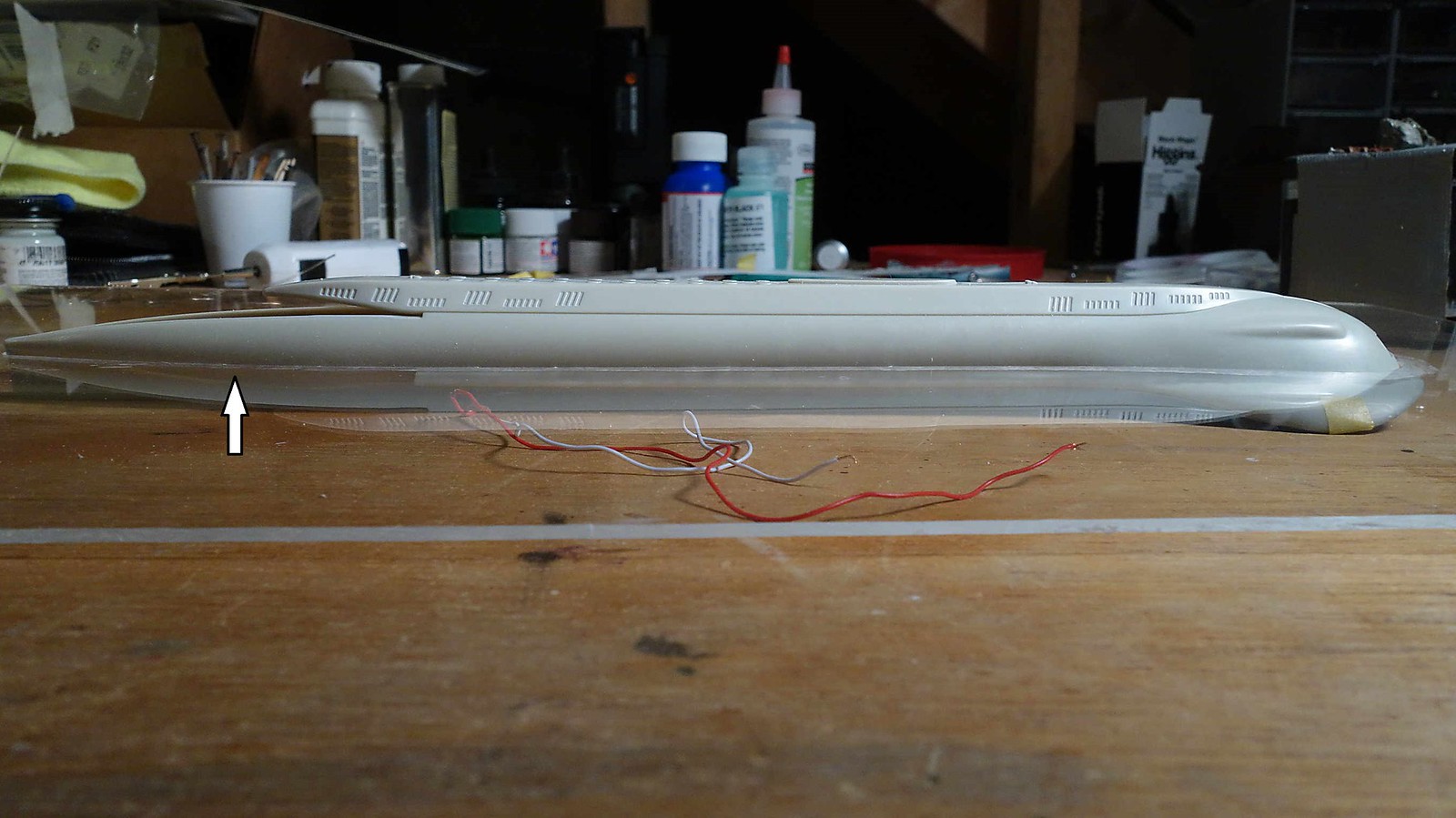

The arrow points to where the PTs sit. You can see the PTs attachment location by where it appears darker. I think that the waterline needs to be raised up some at the back, but it seems pretty certain that I will need to make some mods.

That is all for now.