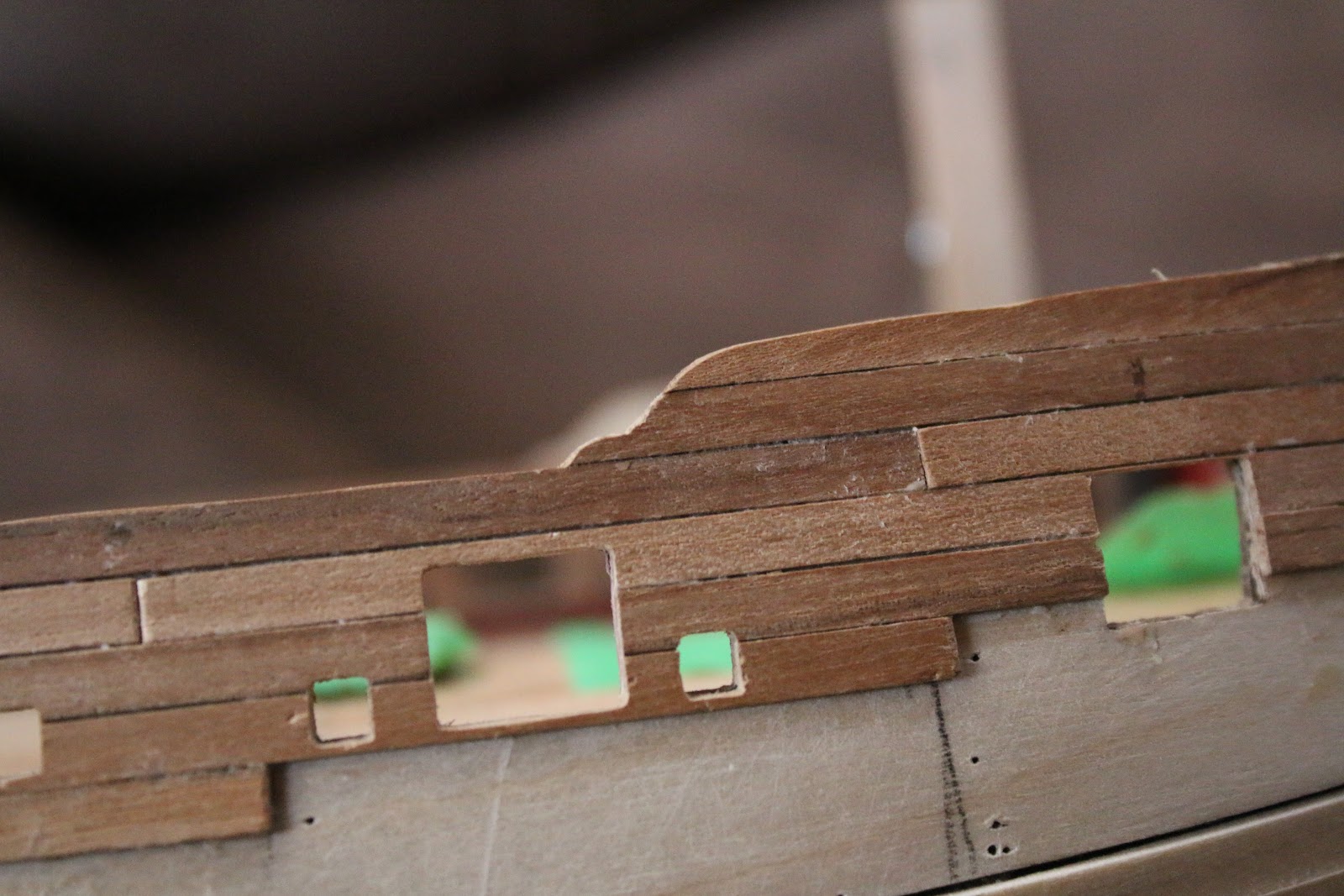

So it has been some time since my last post. This being that the speed and progression of planking is like watching grass grow. Anyhow when I last posted I was just reaching the gunports and was waiting for the new cannons and their carriages to arrive, so I’ll start from there. While waiting for the new guns to arrive in late January, I finally cracked and decided the swell on my deck was bothering me. So about an hour of careful sanding later this is what I ended up with.

The deck was finally flattened out as much as I could get it without sanding past the planking and I'm so glad I did it. After fixing that I got a surge of confidence and decided to put it to use addressing the gallows. The kit provided gallows is not only too large but also inaccurate for a swan sloop.

As seen here in this painting of a model of the Kingfisher by John Marshall the cross of the gallows is a completely different shape as the kit provided one.

Also in my hours of reading build logs I've seen other builders replicate this by scratch building the gallows.

(HMS Pegasus by Blue Ensign)

With all this, I decided the kit provided gallows needed to go and started scratch building.

So the first order of business was cutting a new crossbeam. So I went straight to the laser cut parts sheets and found a section between parts that was even and curved just right. It was not long before I discovered that the upwards beams were too long and the gallows too tall so I gritted my teeth in fear and chopped a chunk off of the beams.

I then finished making the new crossbeam as well as decorated the vertical beams a little and came up with this.

Being very pleased with the turnout I decided the bitts needed a bit of dressing up as well. So I grabbed a pencil and my file and went at it.

Following this, I went ahead and stained the parts And I also dry fitted them.

With that, I also started work on the foredeck bitts.

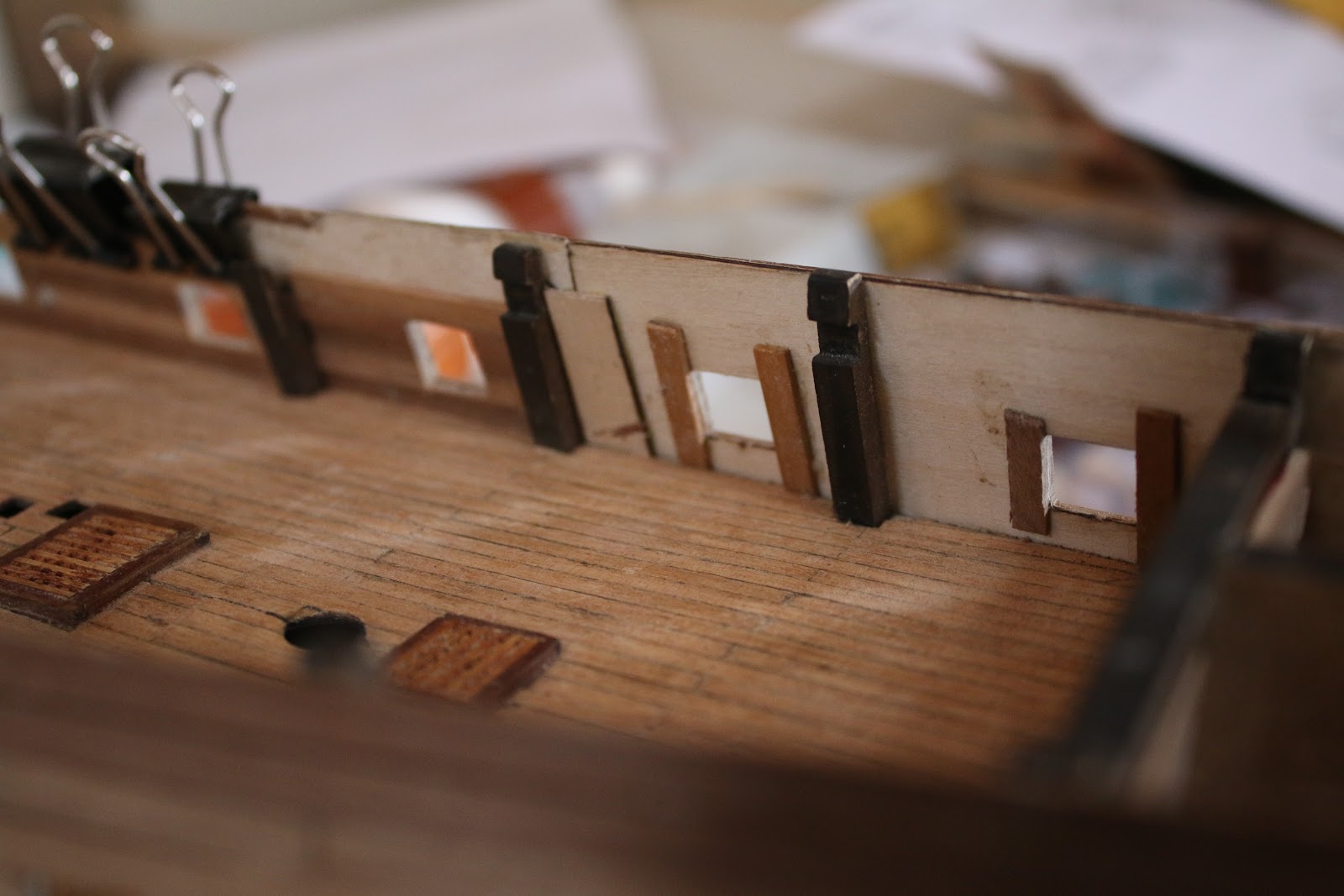

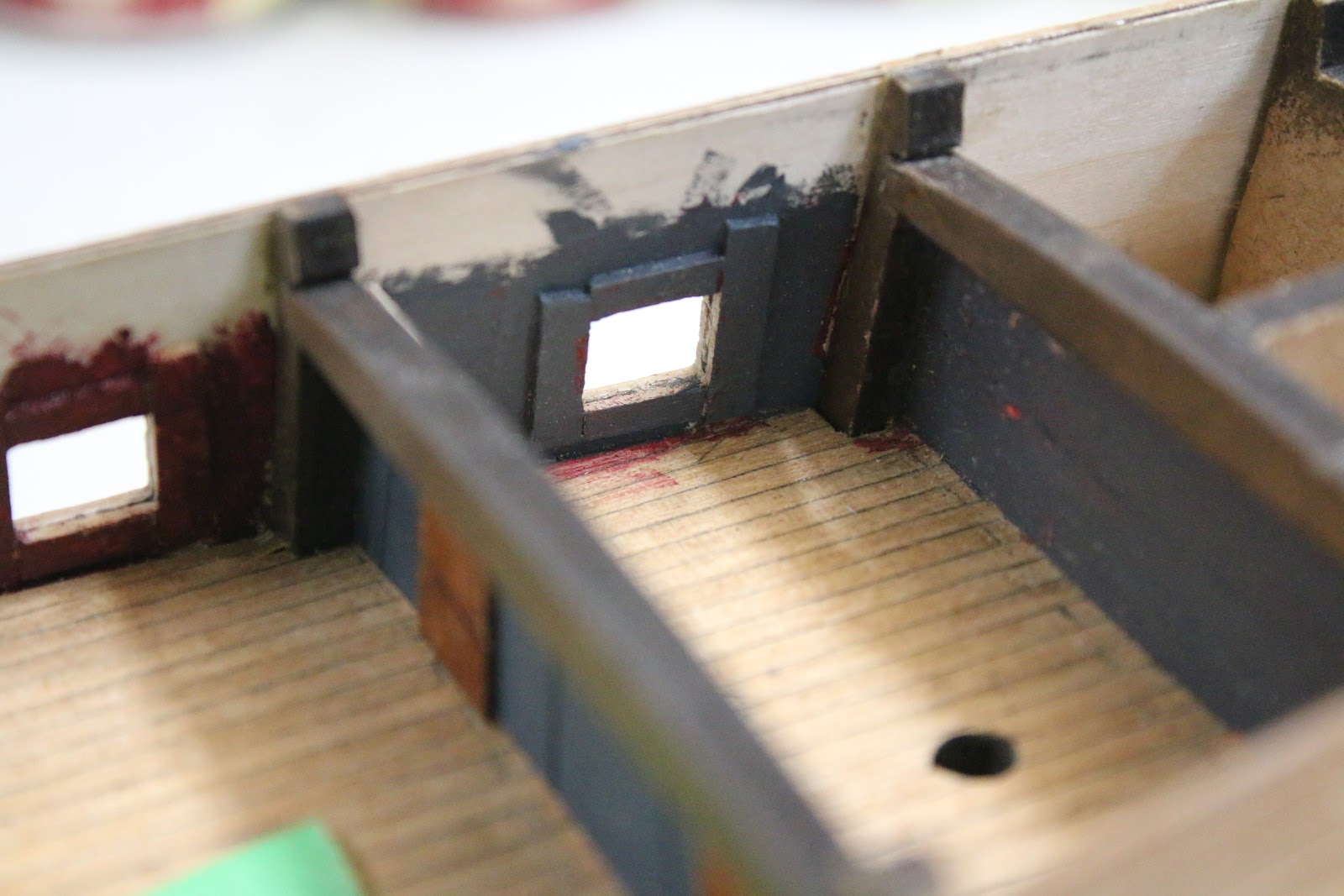

I also started framing the back most gunports on the inside to recreate the width of the hull without where there isn't interior planking.

As well as adding some decor inside the what will be barely visible captain's cabin.

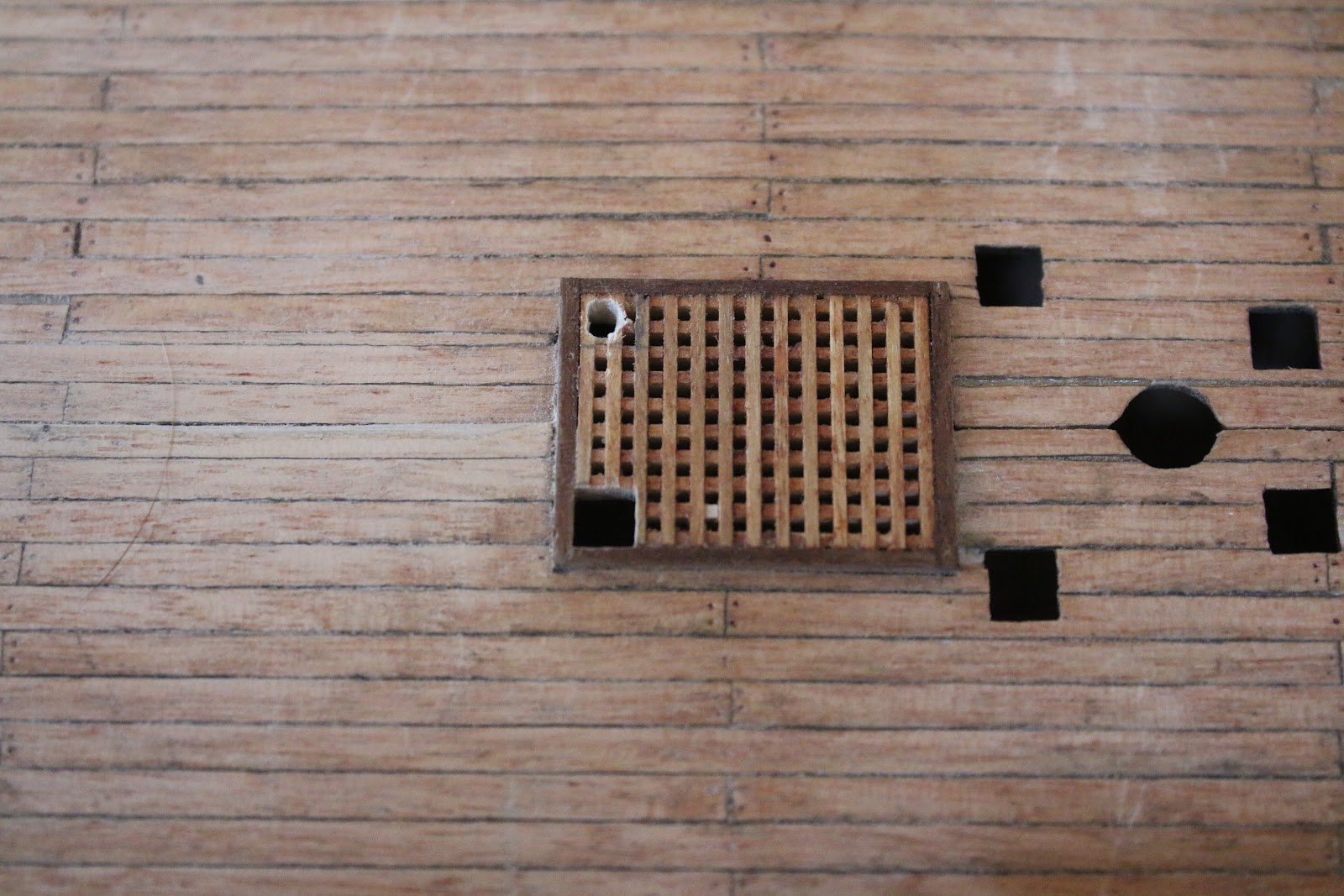

After that, I realized that I had missed a step and forgotten to cut holes in my main hatch for the anchor rope to run into. So with some muttering, I went ahead and fixed this mistake.

After some much needed time away from home. The guns and their carriages finally came in. though I had to convince the post office to give me the cannons due to a mistake in the address but simply pulling up the email confirmation showed it did indeed belong to me.

And with that, I went ahead and attempted to build a carriage. And not surcome to the mind-numbing challenge this is.

Alas, I did succeed.

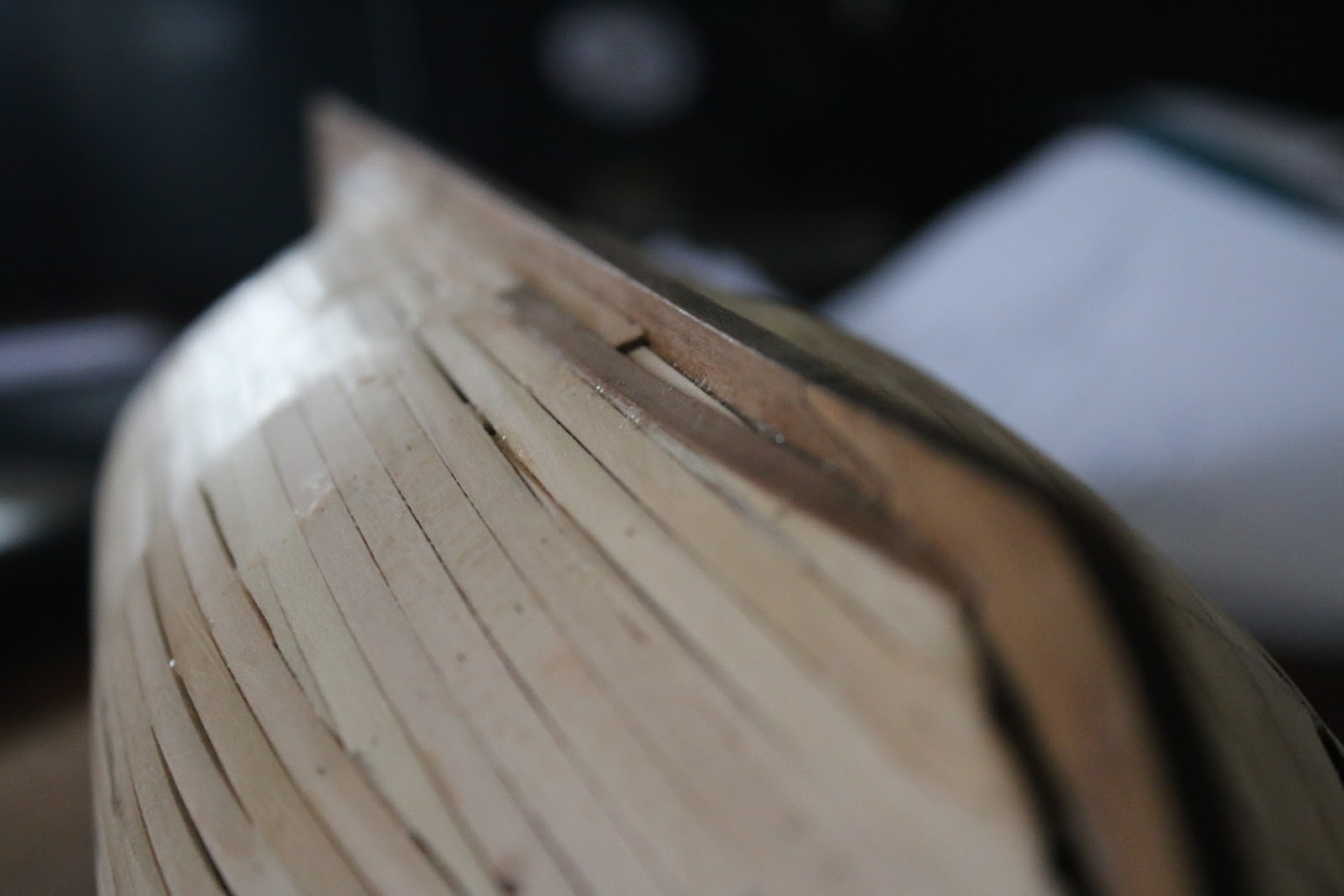

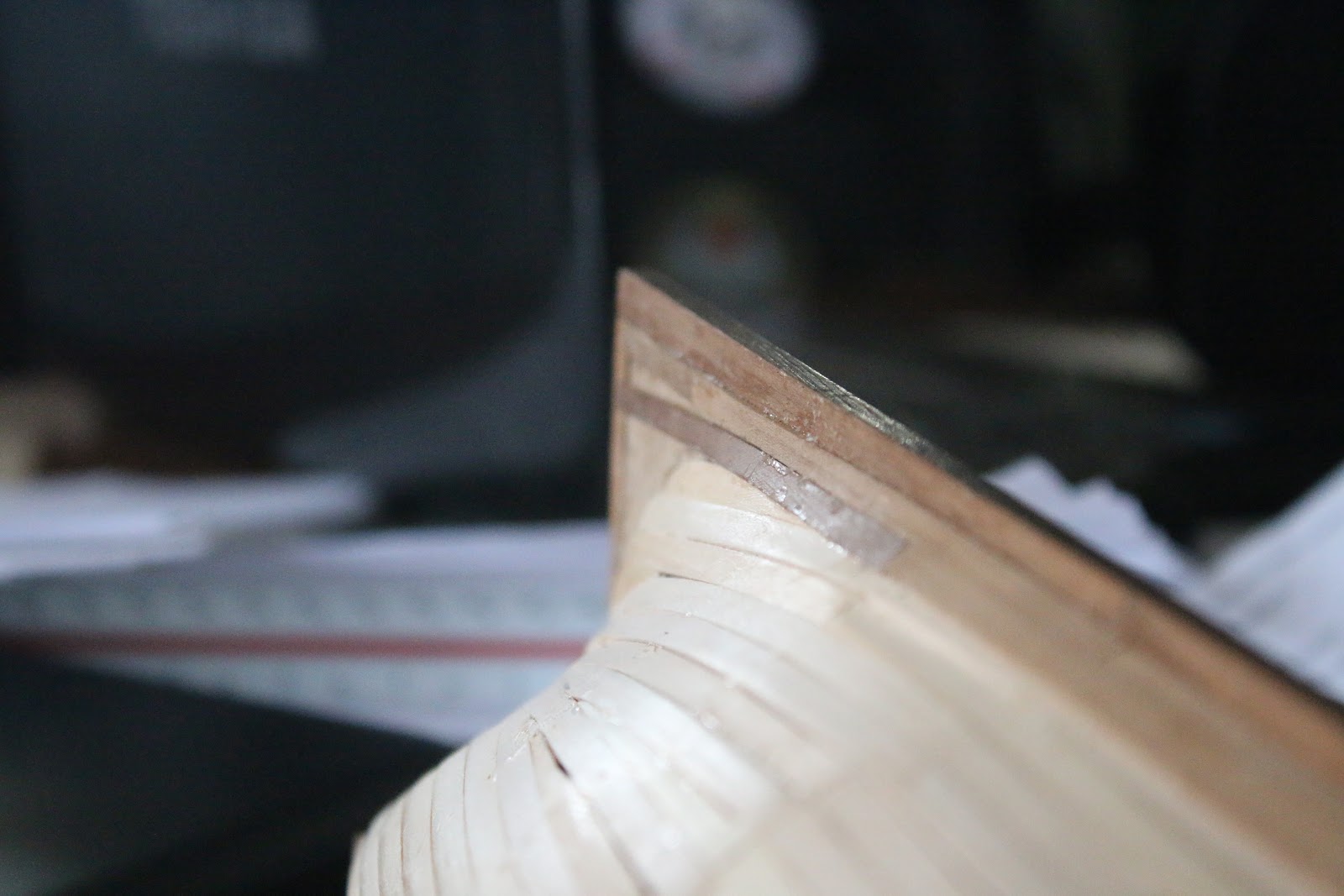

As I'm sure many of you know the Novel virus Covid 19 has reached a pandemic state at this time and due to the rising number of cases in Canada and me being a student I was and still am at home due to classes shutting down. So with nothing else to do, I decided to make a push on with the second planking. Which I’ll admit I had been avoiding. So I started planking away and here's where I left off have been slowly working towards passing the gunports so I can fix and refinish the gun deck.

I also started to work bottom up on the planking. Using the method my grandfather who got me into building ships taught me.

And in the coming days, I worked my way up the hull following the natural curvature.

And a little more planking as well was placed in a wedge plank.

So one of the things that's been bothering me for some time is my lack of knowledge when it comes to blackening my eye bolts and as you can see my last attempt did not turn out.

but I did have a breakthrough and discovered setting them on fire both cleans and blackens them and after seeing it in steel pins.

and with that, I'm now a pyro head.

Anyways moving on I finally put in the transom plate on the back of the ship and also decorated the inside a bit.

I also repainted my little separation wall that I had put in the back of the boat to match.

I then finished framing the gunports.

And then I decided to finally shape the top planks with the plywood template.

And I also finished planking the seen interior planking.

And then while waiting for that to dry I decided to try my hand at a “show” cannon. Which I would say turned out pretty good.

The next day after constructing the cannon I moved the whole model building operation to the shop my family and I have been building for 2 years now.

That night I installed some more planking working my way down past the gun deck.

I also “attempted” to construct the wall for the captain's cabin but I'm not quite happy with it and may very well restart it.

I also painted the interior where it won't be seen. I know it's rough but it won't be seen so I'm not entirely worried about it.

Then moving forwards I went on to installing an extra plank on the bottom of the interior. An idea that I got from Blue Ensign’s HMS Pegasus build

https://modelshipworld.com/topic/15526-hms-pegasus-by-blue-ensign-finished-victory-models-164-scale

I also went ahead and started a second carriage, which while my paint did improve I will not have it in the open part of the deck but rather the first port under the opening in the top decks, due to its misplacement of the upper eyebolts.

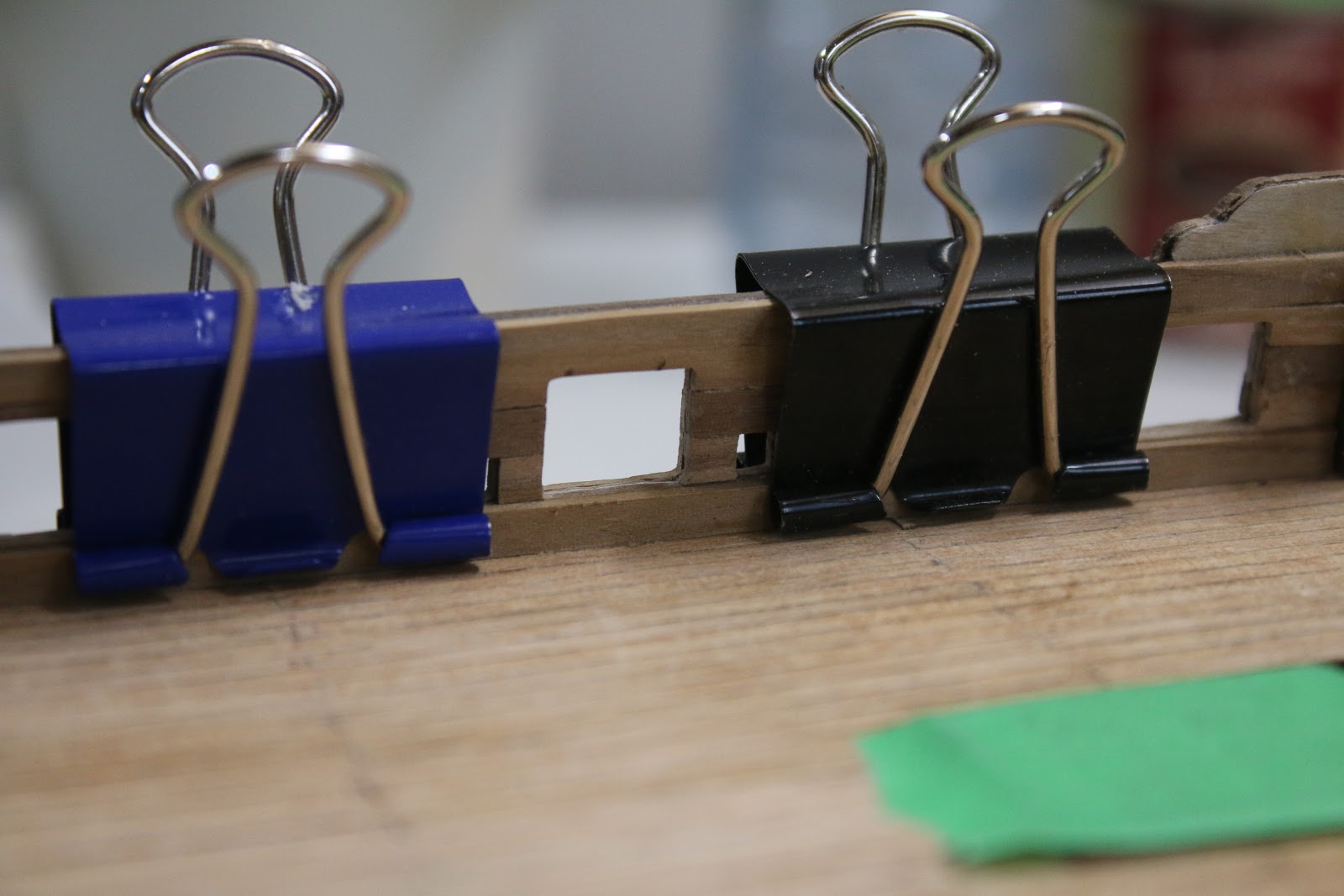

The next day I removed the clamps on the extra interior plank.

And prepared to file and finalize the gunports.

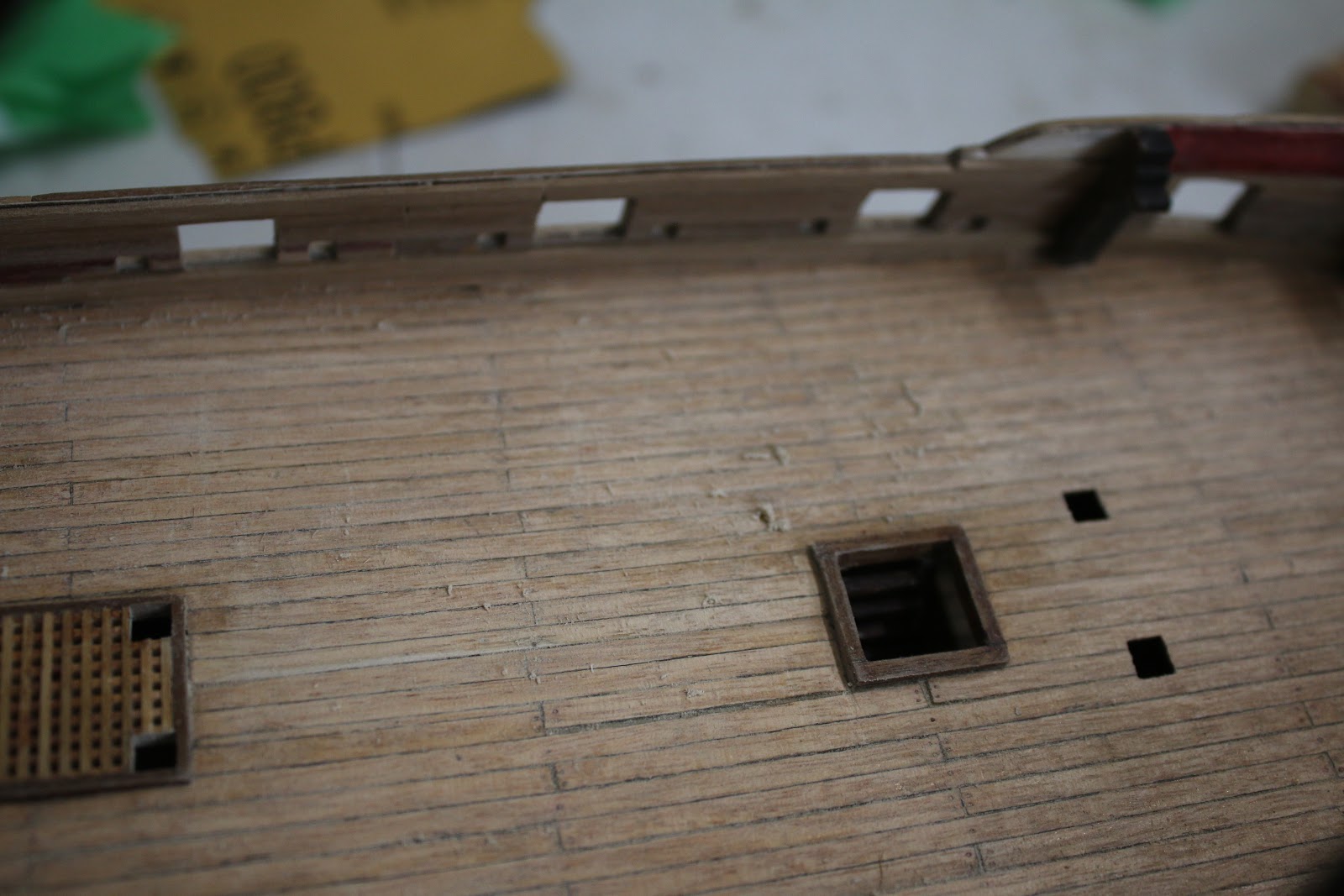

Then finally being past the gunports with the planking I began to prepare the deck for refinishing.

Then using an air hose and compressor, I removed all the dust and dirt from the deck.

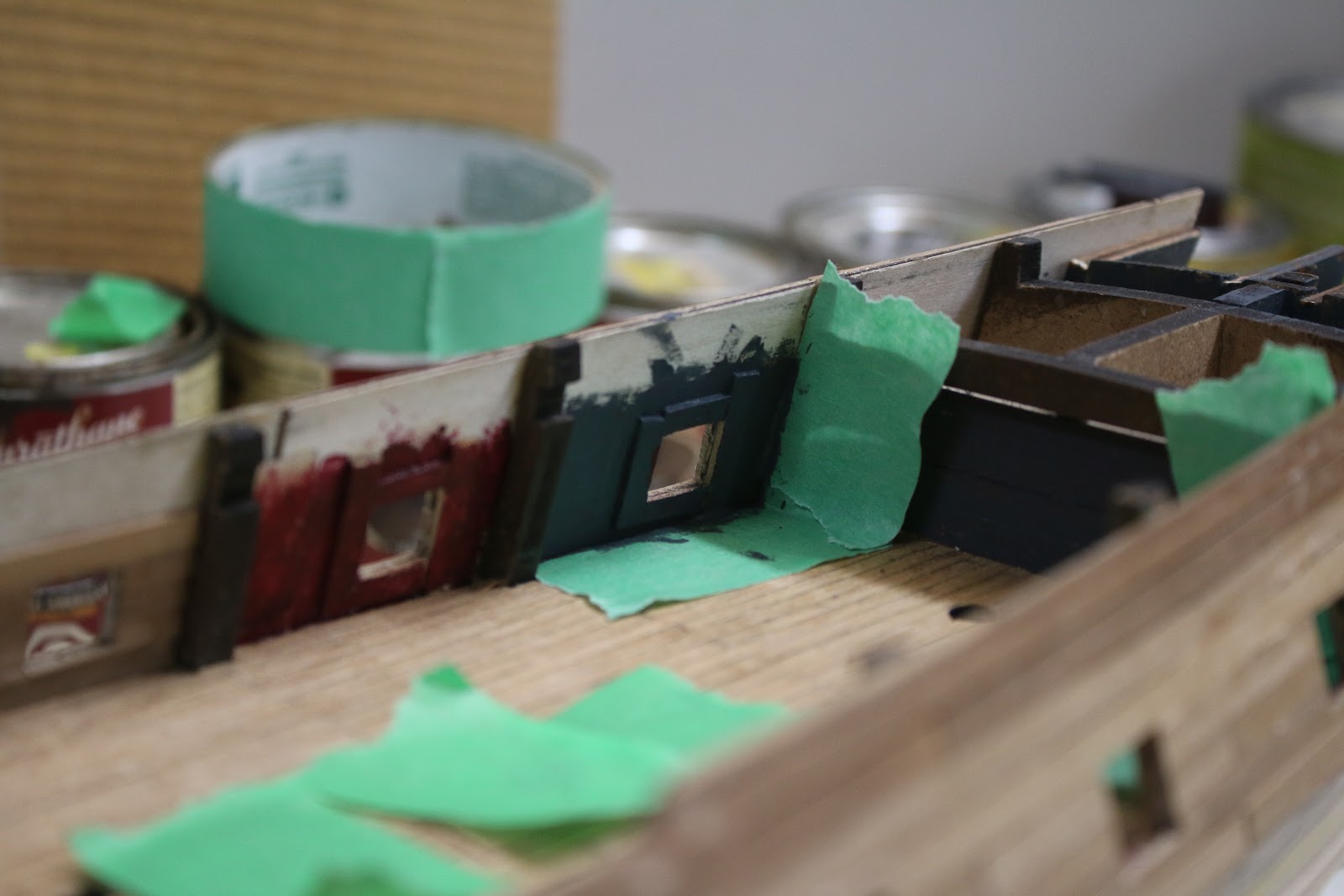

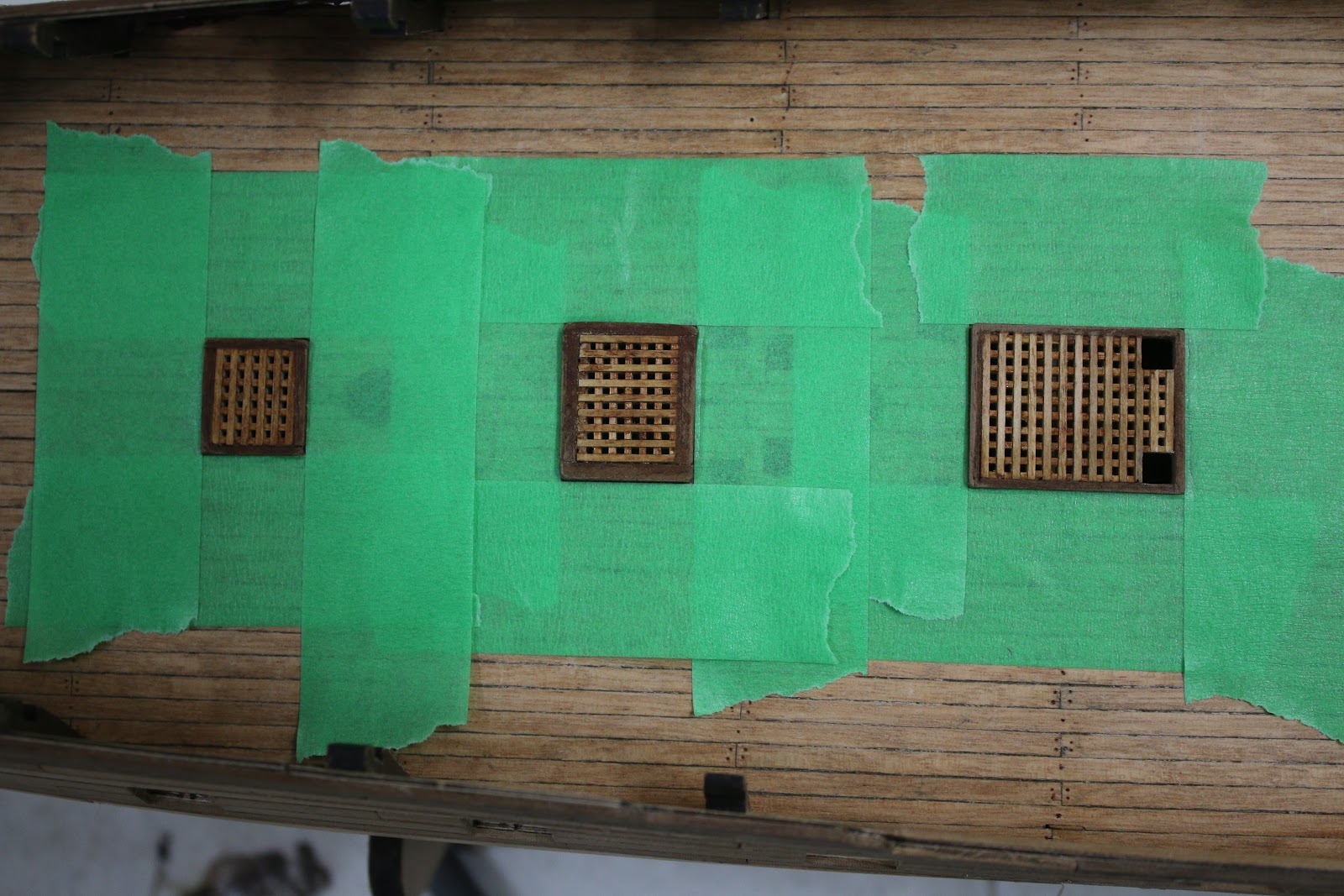

I then framed the hatches in masking tape and refinished them.

I then taped up the interior planking to prepare for the stain.

And finally, I refinished the deck and got the exact finish I was aiming for. Some of the scratches do remain but they are mainly where a cannon will be and would be sliding back and forth and at this point, there's nothing that I can do to fix the scratches, so I’ll just have to live with them.

And here's a few pictures of the ship I took while she dried.

And that's where I left off today. My main focus now will be working on the planking as much as I can and I will also be covering the gundeck up with paper and tape to protect it while I work. As soon as I get a new cherry red stain I will be staining the interior planking and I’m extremely excited to do so. In the meantime between the next post, I wish you all good health in this unusual and trying time and best of wishes.

-Jamie