I snagged this kit a couple of weeks ago and have spent some time on it lately, because I really like the gray/gray paint scheme these things wear, and I do love French aircraft.

Kitty Hawk and Kinetic both make kits, and I picked up the Kitty Hawk for the markings, then realized that I'm going with some of the most generic ones in the kit, but anyway, I also haven't built a Kitty Hawk kit and just wanted to see what they're like.

The fuselage consists of several pieces. Two halves cover the portion from the intakes to the break for the engine cover on the rear. The cockpit is two halves, and slots into the rest of the fuselage sort of like how the Hasegawa Harrier does. This creates a four-way seam, but that is covered by a two-piece spine (I wish it was one piece, but oh well).

In test fitting, I realized the rear portion of the fuselage was going to be a pain if I built it up per the instructions.

Much like the Hasegawa P-40 kit, I think this one is best approached by mating the rear part to the middle part in halves, then working any issues out on the top and bottom seams (especially since the tail covers much of the top seam and the arrester hook covers much of the bottom one.

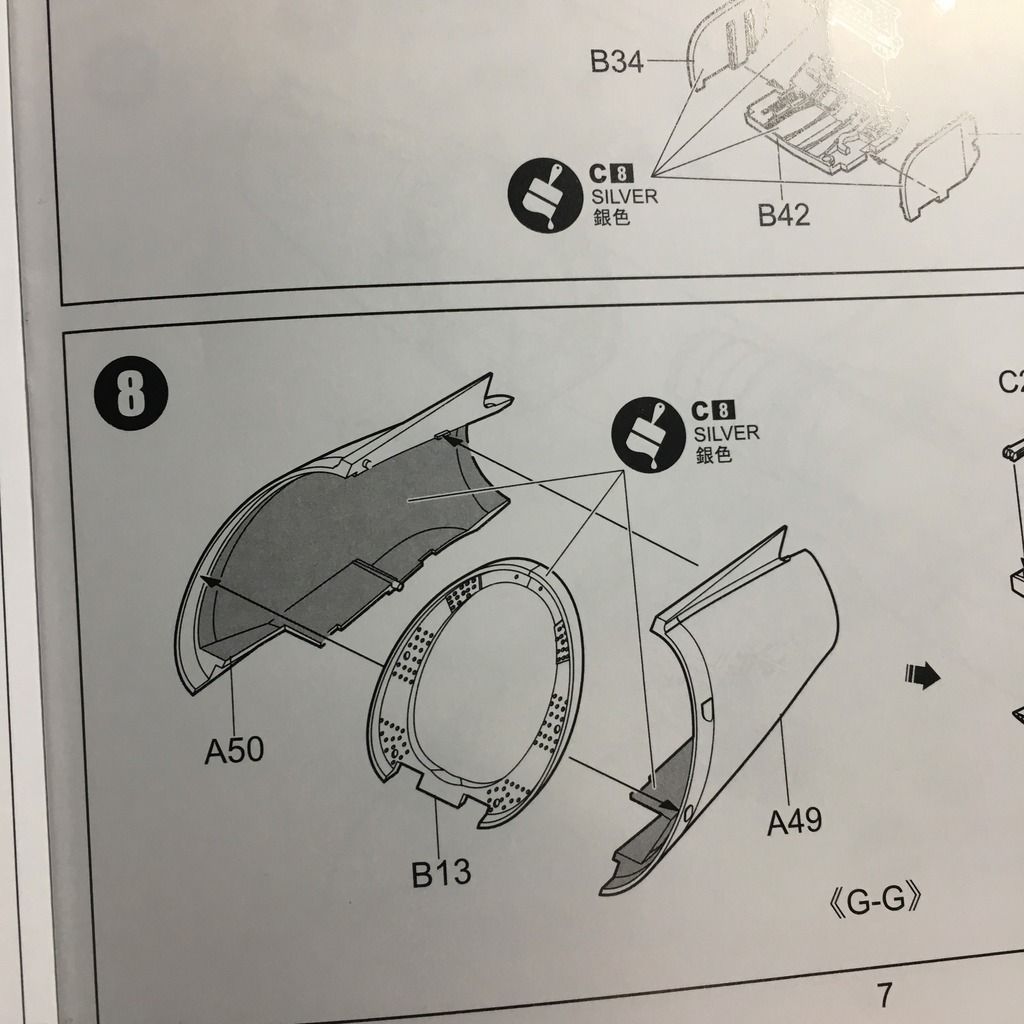

The hard part of this is that the plastic is pretty thin where the joints butt together. The instructions show the rear halves going together around a circular framework (B13 in the pic below), but they don't show any similar bulkhead/framework on the middle part. The piece does, however, exist and it, when installed, provides a better butt join, but there are no locating tabs or anything like that on it.

I decided the best way to approach it was to glue the two framework pieces together, then cut them at the top and bottom so I had two framework halves to match the fuselage halves I was building. This gave the fuselage pieces something to grip while being put together.

Above, you can see the halved B13 connected to half of its opposite number in the middle fuselage piece.

That gave me this on the exterior. I was able to match the curvature, but the joint is a little overscale. I'll force some Perfect Plastic Putty into it and then lightly scribe it so it more closely matches the rest ofthe panel lines.

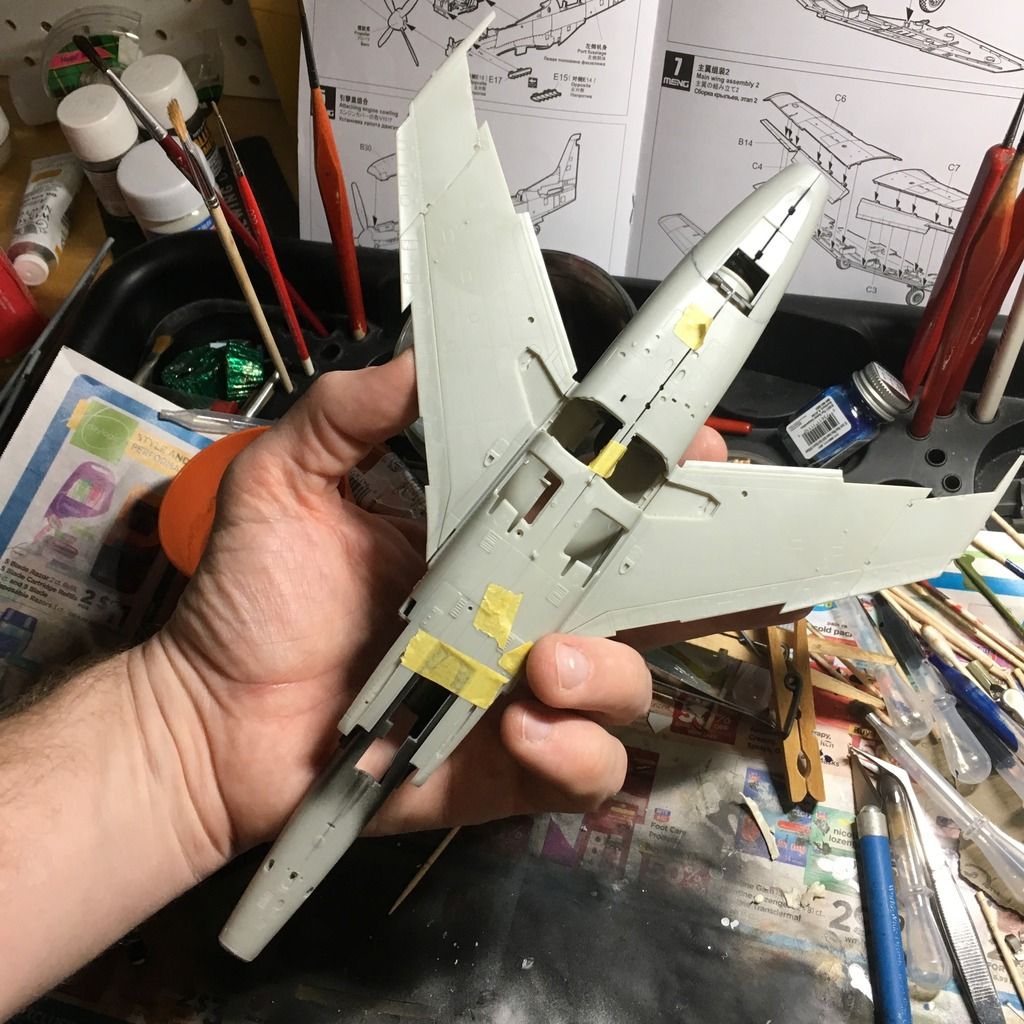

Once that was done, I built up the multi-piece tail fin and most of the wings, then dry-fit the major components of the aircraft to see how well it went together.

At this point, it was time to start painting the internals, so I built up the gear bays and some of the cockpit and got to work.

They insist on giving you a full engine, which is cool, I guess, but in my take just necessitates more nose weight. It's hard to see the engine, so I just painted the fan blades and bulkhead and left it, then glued the fuselage halves together around it.

The fuselage halves went together ok, but there is only one locating pin on the bottom, and this led to a step that I missed when I was assembling them. If I were doing it again, I would have cut some styrene and made tabs on each side to better fit them together. Oh well.

I do like the way the separate pieces on top cover the main dorsal seam.

After this pic was taken, I fiddled with the part a bit to make the mating surfaces more even. Then, some Mr. Dissolved Putty went on the seams, and once dry, I wiped it smooth with a paper towel dipped in Mr. Leveling Thinner.

Next up was the cockpit while I worked the seam on the bottom of the fuselage.

It's pretty straightforward. I used all the kit pieces here because the bang seat was good enough on detail. I built it up, puttied the top seams, then built up much of the rest of the pit before painting it black. I then heavily drybrushed it with NATO Black, then lightly drybrushed it with dark gray.

The instrument and side console details are provided as decals, but Kitty Hawk doesn't note this in the instructions. The instrument panel was four decals, but it was clear where they went, and they snugged down nicely with Micro Set/Sol.

Next up is closing the cockpit and forward wheel bay in the nose piece of the fuselage, then adding that to the already-assembled bits.

And NOT FORGETTING NOSE WEIGHT!

-BD-