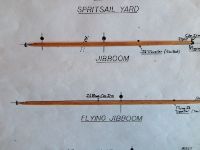

JIB BOOM / FLYING JIB BOOM

Thanks for the heads up JT. I actually typed in bass wood when it should have been birch wood. I am using the dowels that I ordered from Blue Jacket as outlined in their parts list for the Connie. Very reasonably priced, especially since my LHS does not carry them.

This is yet another first for me and I was unnecessarily worried about it as it turned out to be not only easy, but fun to do. As I have been working w/ wood for the first time w/ this model, I am finding it much nicer to work w/ than styrene and am now seriously considering my next build after the upcoming Alabama to be entirely a wood kit. Anyways....

Assembly materials: Brass sheeting, hexagonal styrene, birch dowels

I followed the advice about using a drill to do the tapering using my cordless variable speed propped in my lap, left hand on the trigger, right holding the sanding stick.

It went really quick and easy. I checked it against the BJ scale plans rather than using calipers and adjusted until I got a match (or as close to one as I could)

I finished up by trimming the extra length off the ends and final shaping, then staining w/ min-wax colonial maple.

Using scissors, I cut some narrow strips from the brass sheeting and made bands, one for the flying jib, and one for the cap end of the jib boom. The octcagonal styrrene connector was glued to the band for the flying jib. The BJ instructions did not have much instruction on this, but it did have an image of what it should look like, and I think I came pretty damn close if not right on.

The flying jib boom is offset to Port by 45 degrees and slightly above the jib boom and buts into the bowsprit mast cap. I ended up deciding to use epoxy to lock it in place as I was nervous that w/ all the tension from rigging, there would not be a strong enough bite w/ such little surface area to glue to.

I have to say that I am quite happy w/ the results considering this is my first endeavor.

The black rings on the jib boom and flying jib are travelers for the running rigging that will come into play later. I still need to attach a number of bullseyes and blocks for the rigging, but that will have to wait for supplies in the mail to arrive. As you can see, I used the kits bow sprit and maritngales. They fit the BJ plans profile almost exactly, Although the BJ rigging plans calls for a set of fairleads that I will have to add as well as the blocks and bullseyes.