Thank you! I don't have trouble with the fogging, maybe because the CA I'm using is getting a bit aged (like me) and isn't so "hot" any more. I use accelerator all the time and it doesn't cause trouble either. I find for window glazing that I can't ever fix, the PVA glues just aren't sure enough although I do use Formula 560 Canopy Glue for windows in my railroad structrures. I also use MicroMark's Pressure Sensitive Adhesive for these kinds of apps. My problem is getting the darn stuff on the glazing which is entirely operator error.

Today nothing particularly bad happened. I finished the landing gear, assembled the bombs and started painting them, and modified and completed more machine guns.

After installing the wire loops in one side of all four bombs, I glued them together, sanded the edges to remove the seams and painted the yellow that would form the yellow rings. After two coats of yellow (a mixture of Vallejo and Tamiya). I then cut some Tamiya masking tape strips to cover the yellow in preparation for the olive drab which will follow tomorrow.

This is an old model and the seam fits weren't so hot. Not like the new stuff.

The landing gear is installed first into the upper Gear well sheet. This, in turn, is glued into the bottom wing. Before gluing anything, I tried the fit of this part into the wing, and quickly found out that both resin exhaust pipes leading to the turbos were too high and holding the gear sheets away from their mounting points. I took the Dremel and removed the excess resin until they fit properly.

I then CA'd the main gear struts into position. One of my brass locking arms had separated from one strut. I waited until the main gear was set and then got the locking lever into place and CA'd it fast. Next on was the gear actuating levers which were styrene kit parts. These parts needed a little coaxing since they were now mating with scratch-built metal parts. All in all, everything worked.

When I was okay with the installation, I masked the bases to protect the interior green. This proved to be unecessary as you'll see in a moment. I sprayed it with the Tamiya Bare Metal rattle can spray, followed by Dullcoat.

After I pulled the tape I found that it pulled about half the green left the plastic. Most likely, it's because I don't wash my styrene before painting, and the Model Master Acrylic doesn't have the grip that Tamiya paints do. Makes a great peeling paint effect if I wanted that.

After brush painting to repair the missing paint, I painted the brake lines and the gear was done. I put on a light coat of alcohol/India ink mix to tone it all down. I also did this to the wheel hubs. With that the main gear are ready to install into the airframe.

The tires have "weight flats". The kit's gear had an axle with two flats that aligned to the wheel hub's hole that was also shaped the same way. But the resin gear has a round axle. I had two choices, file flats on the gear axle or drill the wheel hole out to be round. I chose the latter since it was easier to control AND I can rotate the wheels to contact the ground properly before gluing them in place after the plane is finished.

Machine Guns:

The Verlinden resin Brownings have separate very fine barrels and receivers. The problem is they're missing other aspects of the kit's guns that enable them to be mounted correctly in the model. So I'm making hybrids of all of them as I did with the top turret. With the waist and radio room guns, I used the same method, drilling the receiver and shaping the barrel so they were a tight fit and CA'd into place. For the bombardier compartment guns this method wouldn't work, since there's a lug on the barrel portion that goes into a fitting on the window. This part was too narrow to drill the barrel-sized hole, and a straight butt joint would be very fragile. I needed to pin the barrel in place.

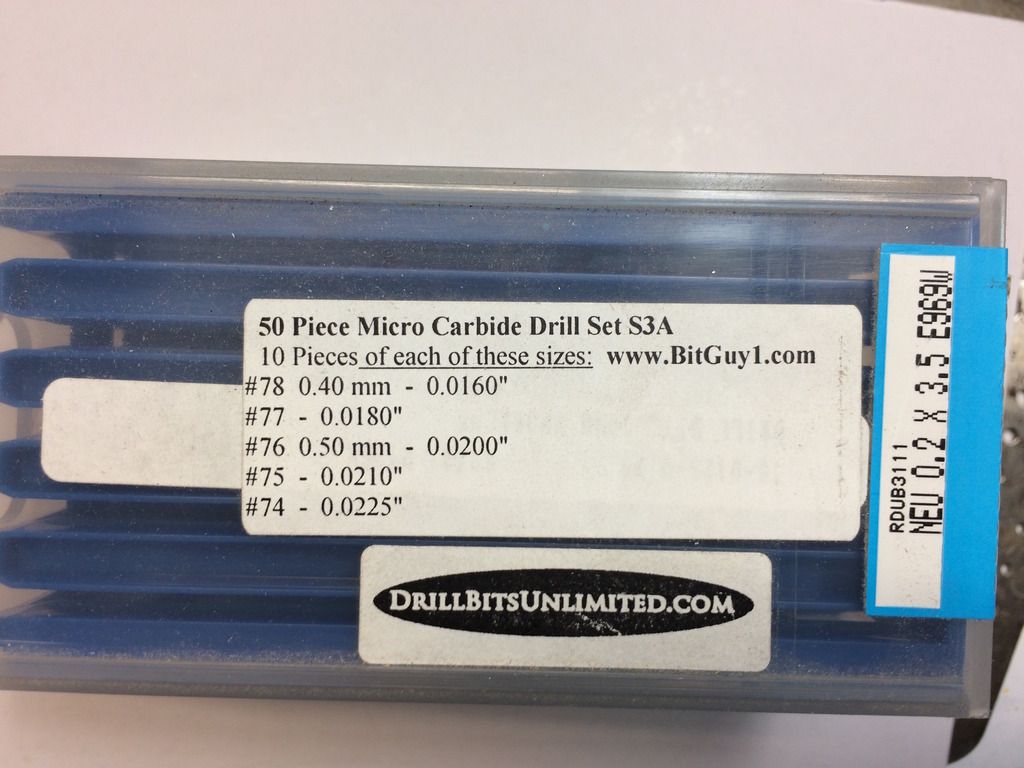

For very small diameter rods I use B and E guitar strings. The E string is 0.009". There's actually no drill size you can easily get that's this small. I have a selection of carbide drills that I buy from Drillbitsunlimited.com. This set has 10 each of small sizes and it's a good barging. But... there's a caveat. These are solid carbide and very brittle. A tiny bit of side thrust and "snap!". They are very sharp and originally are used to drill circuit board fiberglass. That sharpness is a blessing and curse. When drilling brass it's a curse since it grabs on exit and breaks the drill almost every time. I went through a ton of these when building the Missouri working with the PE.

Here's the drill I used. It's a #78 and is oversized for the guitar string, but with ample CA it ultimately held. They all have an 1/8" shaft so there's lots of support. These were originally used in automated drilling machines.

Here's the sequence. I file both the receiver and barrel mating surfaces flat and square. I then use a divider point to make a pin *** in as close to dead center as I can. I then use the #78 to drill both pieces.

The newly joined barrel is reasonably strong. Here are all guns done today.

Before closing up for the day, I painted all the guns Tamiya Gunmetal. I had a problem with the chin turret. Its guns are noticeably longer than the rest and have flash shields on them. The Verlinden replacements are just too small. I may use the kits guns in this one instance. I like to paint the barrel tips silver. I don't know if this is prototypical, but I like the look.

Tomorrow, I'll finish the bombs and mount them to the bomb rack. This will pave to the way to start installing everything into the right fuze half including all the glazing and then put the Fuze together. The seams will need a lot of filling, and being an ancient kit, all the panel lines are raised. I'm not of spirit to shave them all off and engrave panel lines. I would wait until I build the HKM 1/32 scale bird which already has engraved lines. Meanwhile, the wings can also be built. From now going forward, the build is going to accelerate.